Stellantis buys into Li-S battery developer Lyten

Stellantis invests in lithium-sulphur battery developer Lyten, working on a novel three-dimensional graphene material platform. Stellantis wants to get in on what could be a breakthrough in the Li-S sector.

++ This article has been updated. Kindly continue reading below. ++

Utilising Lyten developments, Stellantis aims for advanced Lithium-Sulfur based EV batteries, vehicle lightweighting, and enhanced vehicle sensing solutions. Li-S batteries could deliver more than twice the energy density of lithium-ion and represent an alternative, non-nickel-manganese-cobalt cathode solution, emphasises Stellantis.

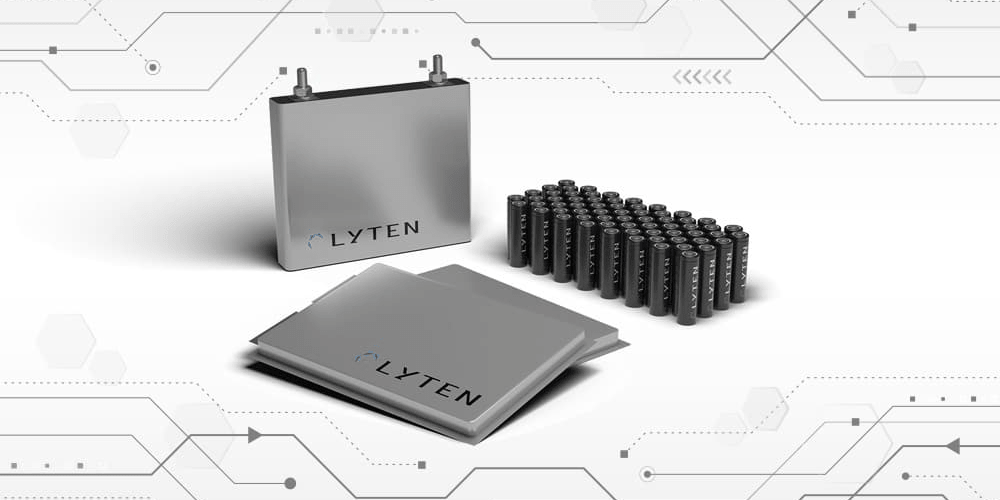

Specifically, Stellantis is invested in Lyten’s 3D Graphene applications, including the LytCell Lithium-Sulfur EV battery, lightweight composites, and novel onboard sensing – all trademarked. The LytCell platform has been in development since 2021, with Lyten targeting a gravimetric energy density of 900 Wh/kg and a start of production and market availability in 2025/26. However, there has been no update in today’s statement on whether these targets still stand.

The Lyten 3D Graphene also took years to refine, according to Lyten. The company describes it as a “decarbonisation supermaterial” engineered from natural gas. It can be tuned at the molecular level to meet the specific requirements of battery applications.

The third achievement Lyten cited in earlier communications is the so-called Sulfur Caging. This is the key to unlocking the performance potential of sulphur by preventing the so-called polysulphide shuttle effect – a process that has previously impaired service life and prevented the practical use of Li-S in battery-powered electric vehicles, the Californians say.

The company initially worked closely with the US government to test the technology for military purposes and spent several years improving the platform’s capabilities in selected defence-related applications.

As for civilian vehicles, Stellantis points to Lyten’s Lithium-Sulfur batteries being free from nickel, cobalt, or manganese, resulting in an estimated 60% lower carbon footprint than today’s batteries. Raw materials for Lithium-Sulfur batteries have the potential to be sourced and produced locally, in North America or Europe, emphasises Stellantis, enhancing regional supply sovereignty. Lyten adds its technology will also have an estimated 40 per cent lower carbon footprint than solid-state batteries.

Dan Cook, president and CEO of Lyten, added, “Unlike two-dimensional forms of graphene, the production of our tunable Lyten 3D Graphene™ has been independently verified to be carbon neutral at scale. We are converting greenhouse gases into a new class of high-performance, high-value carbon materials and are incorporating these tuned materials into applications that will decarbonise the hardest to abate sectors on the planet.”

“Having recently visited Lyten together with our CTO Ned Curic and our head of Stellantis Ventures, Adam Bazih, we walked away impressed by the potential of this technology to help drive clean, safe and affordable mobility,” said Carlos Tavares, Stellantis CEO. “Lyten’s materials platform is a key investment for Stellantis Ventures, in line with our Dare Forward 2030 goal to accelerate deployment of innovative, customer-centric technologies.

Lyten’s Lithium-Sulfur battery, composites, and sensor technologies are initially being produced on its campus in Silicon Valley. The company adds it will soon explore locations for a second phase of output capacity. Besides making EV batteries, Lyten is working with previous customers to start delivering Li-S batteries and 3D Graphene-infused composites for speciality markets in 2023.

Stellantis Group include the Abarth, Alfa Romeo, Chrysler, Citroën, Dodge, DS Automobiles, Fiat, Jeep, Lancia, Maserati, Opel, Peugeot, Ram, Vauxhall, Free2move and Leasys brands.

The partners have not disclosed the investment sum done through Stellantis Ventures.

Update 16 June 2023

Lyten has opened its first automated pilot manufacturing facility. The pilot line at Lyten’s Silicon Valley plant is scheduled to begin supplying lithium-sulphur battery cells for testing to launch customers in the automotive sector, among others, later this year. The production capacity of the pilot line is limited to a maximum of 200,000 cells per year. Both pouch and round cells will be produced there. According to Lyten, the gravimetric energy density of the Li-S cells produced there exceeds that of lithium-ion batteries with NMC chemistry. As reported, Lyten is aiming for 900 Wh/kg. The company expects the start of production and market availability in 2025/26.

stellantis.com, lyten.com (update)

0 Comments