HyMon to improve monitoring processes for H2 tanks

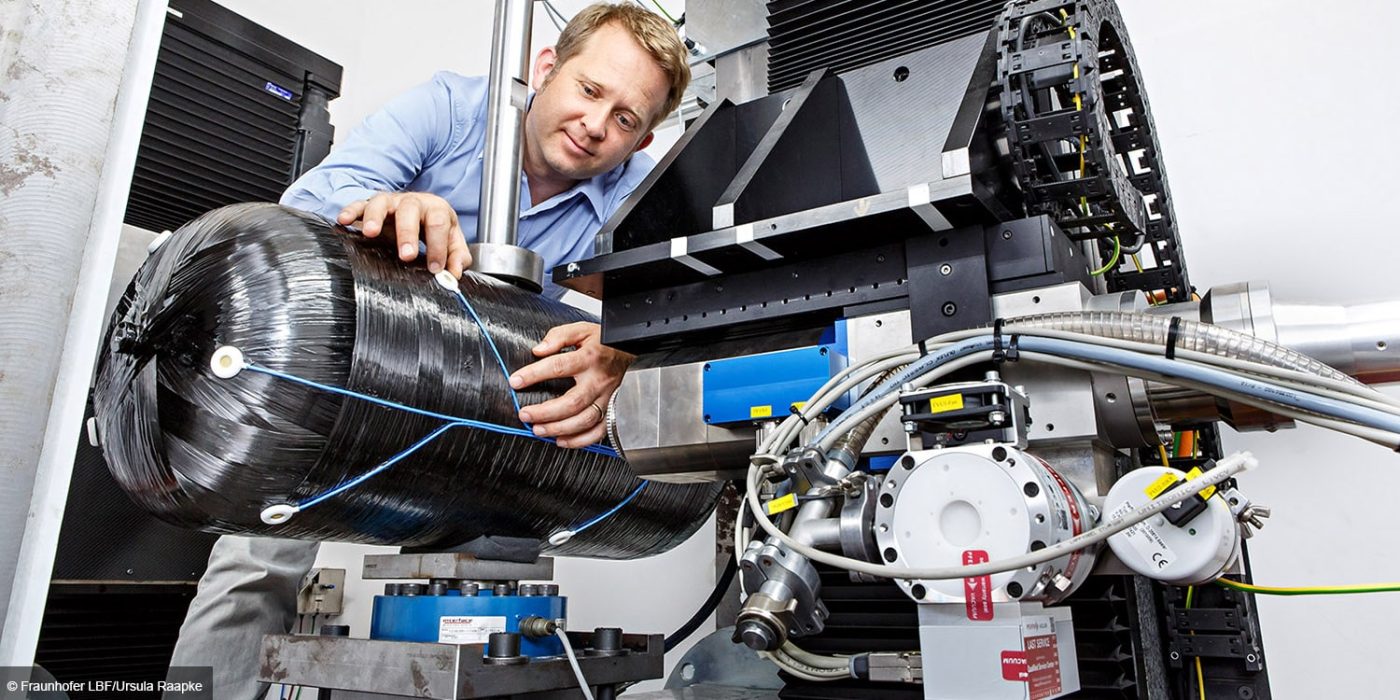

Researchers from the Fraunhofer Institute for Structural Durability and System Reliability LBF are developing a sensor-based on-board structural monitoring system that will enable continuous surveillance of the H2 pressure tanks – thereby ensuring a high level of safety for hydrogen vehicles.

Until now, the H2 tanks in vehicles have only been inspected externally for damage, which, according to the Fraunhofer Institute, is not sufficient in the long term. The development of on-board structural monitoring should reduce maintenance costs “and ensure safe utilization of the tanks over their entire service life.” In addition, the software could provide the necessary data in the event of service or repair.

Currently, researchers are relying on so-called acoustic emission sensors. “If a single carbon fibre breaks in the pressure tank, a sound wave is generated that travels through the fibres. The sensors record the high-frequency sound wave and can thus determine the number of broken fibres,” Fraunhofer LFP writes of the procedure. “Sensors on the tank pick up the high-frequency sound waves when a fiber breaks, and the algorithms detect the broken fibers, which are then counted. If the rate of fiber breakage suddenly increases, this is an indication that the hydrogen tank is at the end of its useful life,” explains Johannes Käsgen, a scientist at Fraunhofer LBF.

The algorithms and methods for detecting the fibre breaks are being developed at Fraunhofer LFB. For this purpose, different types of damage are generated on the test bench using sensor-equipped carbon fibre flat samples, and the “damage signals” are recorded by sensors. This is to ensure that sensors can detect the signals and that the algorithm can correctly assign them. According to Fraunhofer LFP, “in the next step […] the complete sensor system will be tested on thin-walled model tanks and then on high-pressure hydrogen tanks, which will be cyclically stressed under internal pressure until failure occurs.” The goal is to determine how many sensors are needed for on-board structural monitoring and where best to place them.

A total of six partners are involved in the HyMon joint project. These include FEV Europe GmbH, the Fraunhofer Institute for Structural Durability and System Reliability LBF, Hexagon Purus GmbH, mefex GmbH, RWTH Aachen University and Cologne University of Technology. The project is also funded by the German Federal Ministry of Digital Affairs and Transport.

0 Comments