ZF reveals an electromechanical brake system

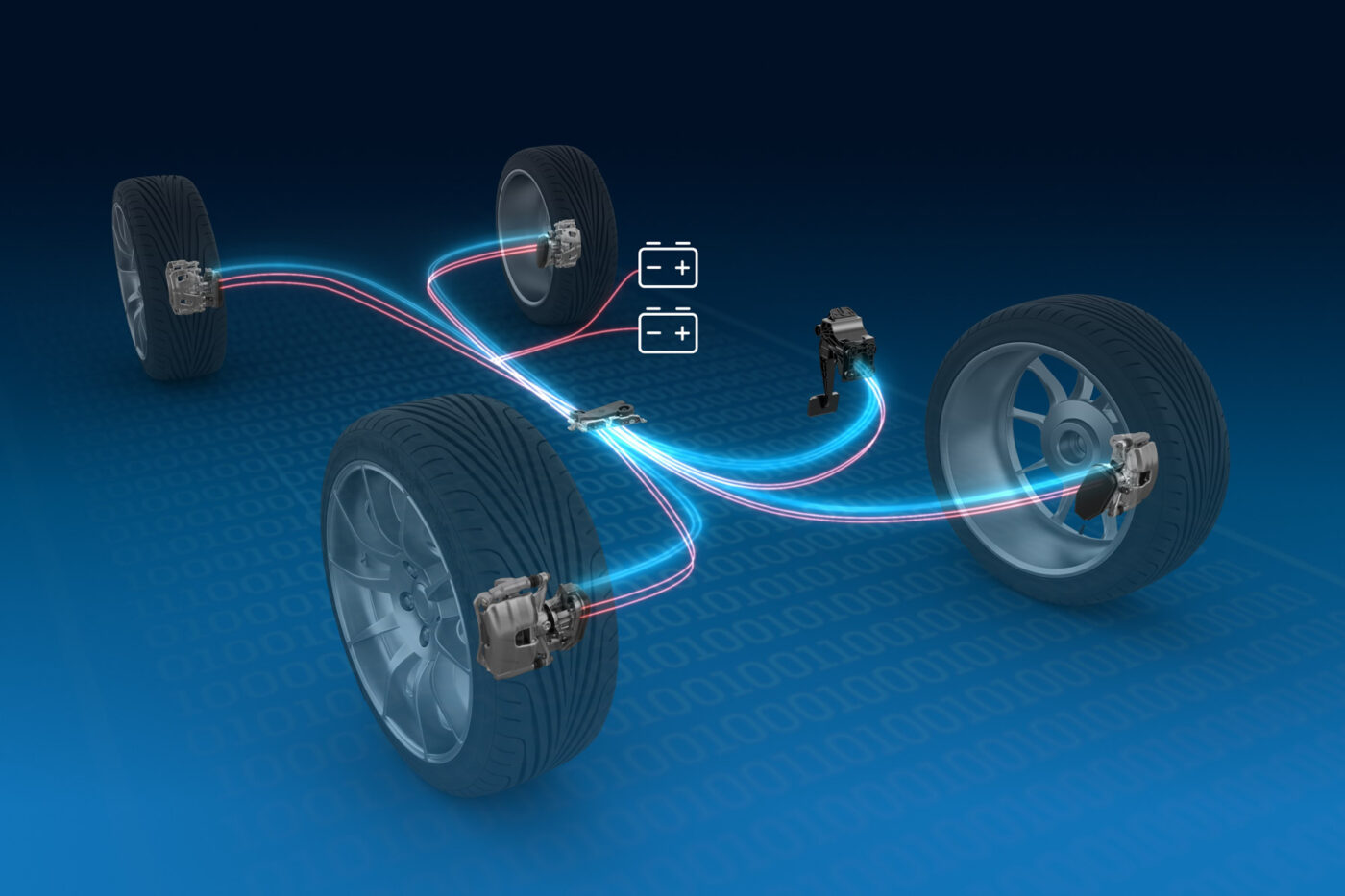

The braking system now presented by ZF involves the braking force generated at each wheel by an electric motor, i.e. without a hydraulic system or brake fluid, as ZF explains in a statement. There is still a disc brake or friction brake, in which the brake pads are pressed against the disc by hydraulic pressure to generate the friction required for deceleration.

This means that the “dry” brake-by-wire system can also be used in cars with combustion engines or various hybrids and is not restricted to electric cars with batteries or fuel cells. However, ZF states that this braking system shows its advantages “especially in software-defined and electrically powered vehicles” and opens up “new freedoms in design and development”. ZF claims “significantly lower assembly and logistics costs” in vehicle production, as the system has fewer parts. According to the press photo, ZF tested the system in a BYD Han.

According to ZF, the new brake-by-wire system, just like the Integrated Brake Control (IBC) already introduced, enables shorter braking distances, better braking energy recovery and lower maintenance costs compared to conventional braking systems.

Explained in a concrete example: in an automatic emergency stop at a speed of 100 km/h, the braking distance can be up to nine meters shorter than with conventional braking systems. In addition, electric cars can achieve up to 17 per cent more range thanks to the improved recovery of braking energy.

This is made possible by one characteristic: in conventional brake systems, the brake pads rest minimally on the brake disk while driving, which creates a so-called residual drag torque – i.e., a driving resistance that has to be overcome with additional energy (from the drive battery). In addition, the brake pads are slightly abraded, resulting in fine dust emissions. With dry brake-by-wire systems, ZF says the residual grinding torque can be “reduced to almost zero.”

This not only reduces emissions but also wear – which leads to lower maintenance costs. In terms of maintenance costs, ZF also points out that the electromechanical system no longer requires brake fluid to be changed over the service life of the vehicle – because there is no more brake fluid.

Incidentally, the braking feel should still correspond to a hydraulic brake – as should the safety. According to ZF, the safety of data transmission and processing and the power supply of the electric motors, is guaranteed by the duplication of all connections and systems, as is also common in by-wire systems in aviation.

“Our purely electrically controlled braking system is a significant addition to our portfolio of networked chassis systems,” said Dr. Holger Klein, CEO of ZF Group. “With such by-wire systems, we are opening the door to a new era of vehicle control.” Klein added that this is especially true in software-defined and electrically driven vehicles, where this type of brake system has even more advantages and opens up new freedom in design and development.”

reporting by Sebastian Schaal

2 Comments