Testing the BMW iX5 Hydrogen: It works – but is it convincing?

You won’t find a test car like this on your doorstep every day: It’s a white BMW X5, of which – admittedly more commonly in grey, silver or black – thousands are on the road in Germany. However, a few blue accents, typical of the BMW i electric subsidiary, and above all, the eye-catching foiling emphasise that this is not a typical X5 with a six-cylinder diesel or plug-in hybrid.

First things first: this is not a detailed analysis of how sustainable the drive concept is over its life cycle and how fuel cell car’s ‘well-to-wheel’ emissions compare to a battery-electric vehicle. That would go beyond the scope of a driving report. Therefore, the focus here is on driving experience. How can you travel with a fuel cell car in Germany today with the current infrastructure, what does it cost, and what are the strengths and weaknesses of the concept and the iX5 Hydrogen from the customer’s point of view? After more than 800 kilometres in the car, we came to a conclusion.

The structure of the vehicle is simple: the fuel cell stack is located under the bonnet in the ‘engine compartment’ and relies on components from Toyota. The Japanese company supplies the cells, while the stack and the overall system were developed in-house by BMW – incidentally, the automated research facility for manufacturing the fuel cell stacks was supported by a further grant from the German government. The larger of the two hydrogen tanks sits lengthways in the cardan tunnel, while the smaller tank sits transversely under the rear seat – together, they hold a maximum of six kilograms of hydrogen. The electric motor, which utilises BMW’s ‘fifth generation’ technology, i.e. the separately excited synchronous motors also used in the iX, i4 and i7, is located on the rear axle. The battery, which serves as a power buffer, is located between the electric motor and the boot floor.

How does a five-million-euro prototype drive?

The fuel cell has an output of 125 kW, sufficient to cover the energy requirement when travelling at a constant speed. In the event of brief power peaks, additional power is drawn from the battery, which is constantly recharged by the fuel cell without the driver noticing. BMW has opted for an electric motor with an output of 295 kW – after all, the iX5 Hydrogen should still drive as dynamically as customers expect from a BMW. With an acceleration of less than six seconds to 100 kph, it can still fulfil this claim, but die-hard BMW fans may disagree, considering its top speed of 180 kph.

But how does a five-million-euro prototype drive? Honestly, it’s surprisingly smooth and very mature for technically being a ‘prototype.’ Step on the brakes, press the start button, select a gear like an automatic and off you go: quiet, comfortable, and powerful on request, with the equivalent of 401 hp. While you could still hear the fuel cell hissing quietly under full load in the first-generation Toyota Mirai, for example, the BMW is as quiet as a battery electric car. The further development of the technology can be felt.

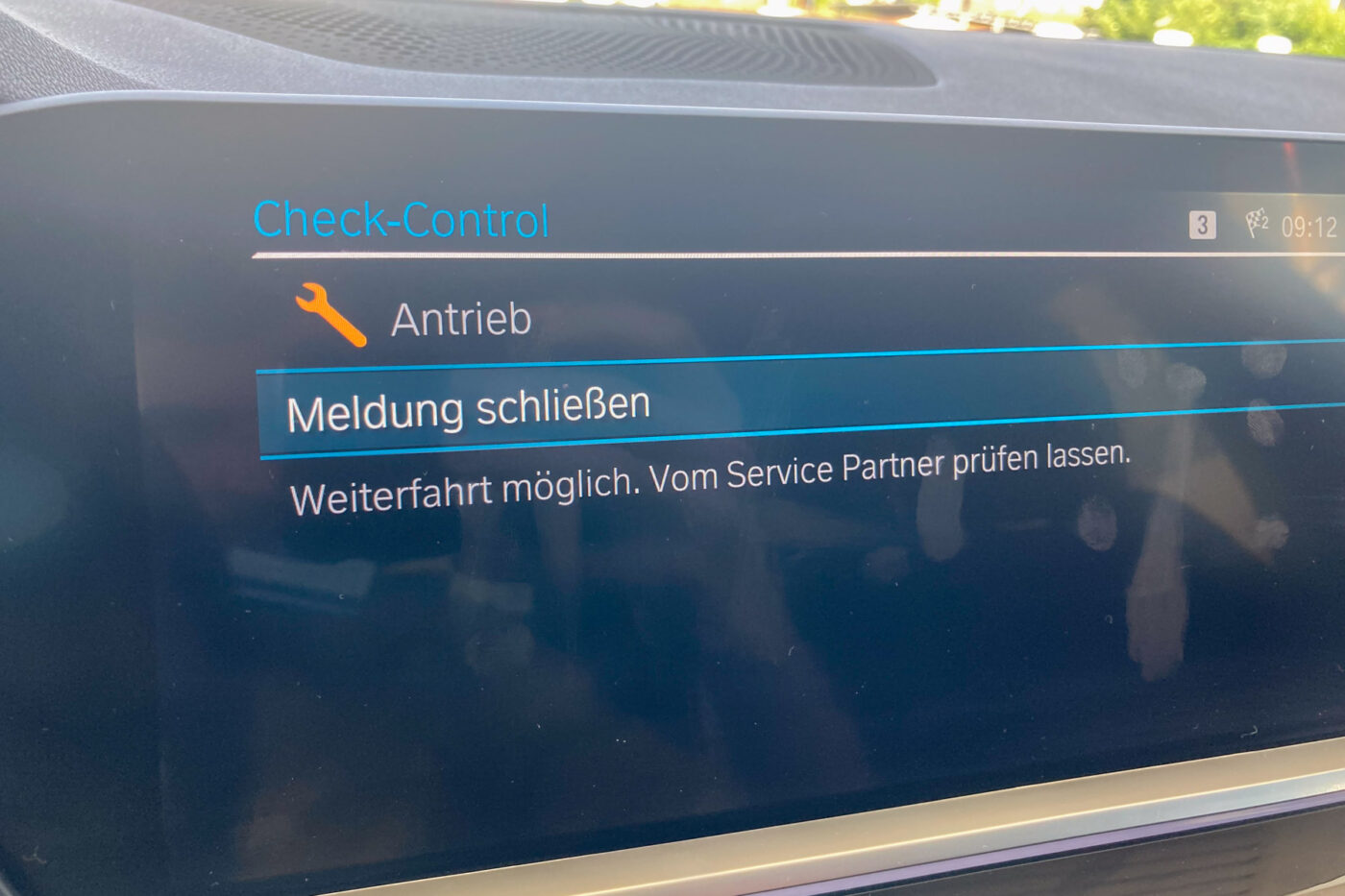

I have never doubted that BMW would deliver a cleanly developed and well-tuned vehicle with the iX5 Hydrogen. The German carmaker has been cooperating with Toyota on hydrogen technology since 2013 and has already trialled fuel cell prototypes based on the 5 Series GT before the iX5 Hydrogen. BMW has even more experience with hydrogen, at that time still for combustion engines. And the battery-electric series models have long since proven that the developers can tune electric drives. The iX5 Hydrogen functions exceptionally well. The prototype is only noticeable in the details. In the fuel consumption indicators on the displays, the representation “kgH2/100km” without spaces looks a bit weird; after all, diesel or petrol is not added in the case of combustion engines. And there can be drive error messages, especially after a warm start or refuelling – but BMW pointed out in the run-up to the test drive that we can ignore those.

However, the decisive aspect for (potential) customers is the infrastructure – similar to the early days of battery-electric mobility. Where do I get the hydrogen? What does it look like on long journeys when you leave the radius of action around your familiar petrol station near home? And what about the range in general?

That’s why we set off with the iX5 Hydrogen, covering 800 kilometres of motorway and country roads. At the start in Düsseldorf, the fuel level was around 80 per cent, according to the onboard computer, and the displayed range was 357 kilometres – BMW has opted for a combustion engine-like fuel gauge and not a percentage display as is often found in battery electric cars. The first, admittedly conservatively planned refuelling stop took place in Limburg an der Lahn. The next refuelling station was in Wiesbaden, which would have meant a slight diversion from the originally planned tour – and if (for whatever reason) the refuelling process didn’t work, the diversions to Frankfurt would have been even longer. If it doesn’t work out in Limburg, Wiesbaden would be plan B – that was the thinking. I didn’t want to go straight to the limit at the first hydrogen refuelling stop in a few years. Just as the battery newcomers don’t usually drive to the charging station for the first time with a single-digit remaining range.

There were no major hurdles when refuelling in Limburg. Although the user experience could be improved (you first have to authorise payment at a terminal on the far right of the picture using the H2 Mobility card and a PIN, then connect the fuel nozzle to the vehicle and then start the refuelling process at the terminal via a green button), the refuelling itself went smoothly. After five minutes and ten seconds, the tank was full again – at the start, it was still roughly 35 per cent full. We will come back to the costs of the refuelling processes later in an overall calculation.

But it also showed that the quick five-minute refuelling process was not a real advantage here. After all, there was no time to visit the toilet or buy a coffee while refuelling. So, as with the combustion engine: first refuel, then re-park and take a break. The time from leaving the motorway to getting back on was similar to that of a modern electric car. Of course, the break was shorter than with an older electric car with a charging time of 30 or 40 minutes, but EVs have made significant progress in this area in the last few years.

With a BEV, a second stop would not be necessary

With a full tank and a range of 429 kilometres on the on-board computer display, we set off on the next stage. And here – as with battery electric cars eight years ago – things got a little tricky. Even if the real range was slightly less than the onboard computer indicated, we would have reached our destination with 429 kilometres, albeit with a fairly empty tank. However, there is no H2 refuelling station available close to our destination, so we had to plan a second “safety” refuelling stop on the outward journey in order to have enough hydrogen for the first leg of the return journey. Unlike the battery electric car, the iX5 Hydrogen with the fuel cell cannot be charged at the destination, either via a socket or wall box charging station.

The iX5 Hydrogen requires some manual planning, which is probably more due to its prototype status. The H2 Mobility app is integrated into the infotainment, which can be used to find hydrogen filling stations and retrieve some information – including the address, which can be directly transferred to the navigation system as a destination. However, the refuelling stations are listed bluntly according to distance from the current location. So you should know roughly where there are service stations along your route, because the list is filled with all possible locations in every direction. For a later production model, as BMW is aiming for by the end of the decade, integrated route planning similar to the software used in battery electric cars should be possible.

Back to our journey: in this case, the H2 filling station in Bad Rappenau was a logical choice, close to the motorway on the site of a car depot. During an initial route check in the H2 Mobility smartphone app a few days before the journey, there was a slight shock: three consecutive refuelling stations along my route (Wiesbaden, Bad Rappenau and Fellbach near Stuttgart) were offline due to maintenance work. On the bright side, at least I had freshly serviced fuelling stations for the trip, which worked quite reliably. If you want to look at it critically, three consecutive refuelling stations being out of service would have left you stranded if I had set off without a plan. Fortunately, it didn’t come to that.

After just 182 kilometres, however, the tank was already well emptied again on arrival – for test purposes, we drove a little faster than the recommended speed on the motorway at times, as many diesel X5s are also driven at over 130 kph on open motorways. Accordingly, after refuelling in Bad Rappenau, the onboard computer only showed 314 kilometres of range, given the latest average consumption. Incidentally, I saved time during this refuelling process compared to the battery electric car – refuelling and getting back on the road took less than ten minutes, including some waiting time at the traffic light. But you can also look at it another way: Since I could have charged an electric car at my destination, this refuelling/charging stop would not have been necessary because I could have arrived with zero kilometres of range remaining. So, another ten minutes lost.

But one thing is clear: the remaining 75 kilometres to the destination were no problem with a full tank. The next day, the hydrogen fuel from Bad Rappenau lasted all the way to the station in Limburg – a total of 330 kilometres. The 255 kilometres back to Limburg were especially economical. The consumption indicator for this section was 1.3 kilograms of hydrogen per 100 kilometres.

To complete the test, we planned a final refuelling session in Ratingen shortly before the destination in Düsseldorf. While the stations in Limburg and Bad Rappenau are designed as stand-alone hydrogen refuelling stations, the pump in Ratingen is integrated into an existing Shell filling station. The fuelling process is slightly different here, as there is also a rotating fuel gauge with a classic nine-segment display. However, the refuelling itself went similarly smoothly. And we didn’t have to wait at any of the refuelling stops or had another fuel cell vehicle directly in front of us – which might have resulted in a short wait until the filling station had added enough hydrogen.

The fuel consumption chapter will follow shortly, but this much can already be revealed: After the 157-kilometre stage, we refuelled with 3.01 kilograms of hydrogen for 50.42 euros. If we had travelled this distance with a Tesla Model X of comparable size, the costs – calculated using the average consumption of 26.8 kWh/100 km – would have cost us around 15 euros at the Supercharger rather than 50 euros.

We noticed considerable variations in consumption and range during the test depending on the speed. With a relaxed motorway driving style at 130 kph or the applicable speed limit, it was between 1.3 and 1.4 kg/100 km. In the most economical case, we had a range of 492 kilometres according to the display after refuelling to 100 per cent. However, if you increase the cruising speed with the iX5 Hydrogen and drive at the speed of a diesel X5 on open motorways, the onboard computer only indicated a range of 314 kilometres after refuelling. Consumption was then more in the range of 1.8 to 1.9 kilograms – and with a maximum of six kilograms in the tank, 300 kilometres is a realistic range. In practice, even a little less if you want to avoid rolling up to the petrol pump with an empty tank.

No large range reserves

During our test, the onboard computer showed an average fuel consumption of 1.4 kilograms over 855 kilometres – a calculated range of 429 kilometres for a full tank. The BMW indicates a fuel consumption ex works of 1.6 kilogrammes over 13,891 kilometres, reducing the range to 375 kilometres. Around 400 kilometres on average, almost 500 with an economical driving style and more like 300 with a sporty driving style – these are figures that a battery-electric BMW iX xDrive50 can also achieve. Thus, We could not grasp this superior range of fuel cell cars; in fact, the iX5 Hydrogen is comparable to its BEV competitors. However, that also means there are no large reserves, for example, for energy-intensive operations like towing a trailer. A trailer load was not registered for the prototype anyway, but that could change for a series model.

As described above, we would hardly have been any slower with an iX xDrive50 on our test route; the time advantage of the shorter refuelling process is not so significant on long journeys. However, with an iX – similar to the Model X – we would have been significantly cheaper in terms of energy costs, as the bill shows.

For the first refuelling in Limburg, we paid 49.55 euros for 3.52 kg. In Bad Rappenau, we filled up with 4.06 kg for 72.07 euros. It was the only refuelling process for 17.75 euros per kilogramme. At the other stations, it was 16.75 euros. On the way back, we refuelled again in Limburg, this time 4.56 kg for 76.38 euros. And then again in Ratingen. Here, it was the above-mentioned 3.01 kilogrammes for 50.42 euros.

BMW iX xDrive50 would hardly be slower, but cheaper

That makes a total of 248.42 euros in refuelling costs. The conversion to the 855 kilometres driven by us is not possible because the vehicle was not filled up to 100 per cent at the start of the route. So we use the average consumption: with our test consumption of 1.4 kg/100 km, it would be 23.45 euros per 100 kilometres or 200.50 euros for 855 kilometres. With the ex-works consumption of 1.6 kg/100 km, it is 26.80 euros per 100 kilometres or 229.14 euros for our test route, if we take the cost of 16.75 euros per kilogram as the basis, which is the more typical price for hydrogen at 700 bar.

For comparison, according to spritmonitor.de, the BMW iX averages 23.7 kWh/100km (at higher speeds, consumption of around 30 kWh/100km is also possible, no question). With 24 kWh/100km, even with the ad-hoc price from Ionity, the cost per 100 kilometres is only 16.56 euros – or 144.59 euros for our test route. With the ‘Ionity Passport Power,’ it would be 9.36 euros per 100 kilometres and 92.01 euros in energy costs – whereby this amount already includes the 11.99 euro monthly fee. Without the fee, you get 4.78 kilograms of hydrogen for 80.02 euros – which is enough for 341 kilometres with our test consumption. And not 855 kilometres.

Incidentally, the supposed advantage of fuel cell cars being lighter than heavy battery electric cars does not apply to the iX5 Hydrogen. The vehicle registration document states a kerb weight of 2,570 kilograms and a permissible gross weight of 3,150 kilograms. It remains to be seen what the optimisation potential would be if a vehicle were consistently designed as an FCEV from the outset and the components were not all installed in a combustion engine. What is clear, however, is that with a kerb weight of 2,585 kilograms and a gross vehicle weight of 3,145 kilograms, an iX xDrive50 is on the same level, except for a few kilograms. So, as with the practical range, you could say that the battery can already do what the fuel cell promises.

Conclusion

To answer the question posed in the headline: I am not sufficiently convinced by the iX5 Hydrogen to see a future for hydrogen cars in Germany and Europe (and, honestly, in the rest of the world). There are also problems in the vehicle, for example, with the space required for the many components. With the current and somewhat more advanced technology, I don’t see a small and affordable fuel cell car, as is currently called for in battery electric cars. There would have to be huge leaps in efficiency. Until then, fuel cell cars will remain as large and heavy as the BMW. The technology simply requires a lot of space. It works but is not suitable for mass production. And it is also expensive.

Two points in particular don’t convince me about the hydrogen ecosystem in cars: the refuelling technology and the infrastructure. It is clear from the basic laws of physics how many kilograms of hydrogen can be stored per cubic centimetre at a specific temperature and a certain pressure (in our case, 700 bar). In the iX5, the two pressurised tanks take up an enormous amount of space. Further development of the tanks would perhaps make them somewhat cheaper and lighter – but there is nothing to be done about their size at 700 bar pressure. The tank has to be bigger if I want to store more hydrogen in a car to increase the range. A higher energy density is possible with a higher pressure, for example, but this puts more stress on the tanks and requires an entirely new infrastructure. Or switching to a different type of storage, such as -253 degree cold liquid hydrogen (sLH2), as favoured by Daimler Truck for its fuel cell truck. But that also requires a new infrastructure and poses further challenges – especially in private cars.

Then there is the infrastructure itself. The hydrogen refuelling stations are complex, maintenance-intensive and expensive (even compared to an HPC park including a transformer). At the end of 2023, BMW CEO Oliver Zipse said that fuel cell technology was “the missing puzzle” in regions with insufficient charging infrastructure for electric cars. And his recent visit to China and Japan “reinforced” his assessment. I also see the challenge of directly electrifying cars, trucks and buses in the booming mega-cities of some developing countries with already overstretched power grids – or the simply necessary vehicles in remote regions of China or, for example, in villages in the Peruvian Andes. However, I wonder whether the complex fuel cell and hydrogen refuelling station technology in these regions will provide the solution when, even in Germany, the refuelling stations are sometimes offline for several days for maintenance work.

It is also clear that the vehicles are hardly marketable at the current cost level. Toyota virtually admitted in November 2023 that the Mirai was anything but a commercial success. Only 22,000 vehicles have been sold worldwide since 2014, which is unlikely to have covered the development costs for two generations of the vehicle. The current hydrogen prices in Germany – or even in California, where they have recently risen to 30 dollars per kilogramme – are not exactly an advertisement for fuel cell cars. The German carmaker has yet to reveal how expensive and how large a possible BMW series vehicle with a fuel cell could be.

3 Comments