Mahindra opens EV production and battery assembly plant in India

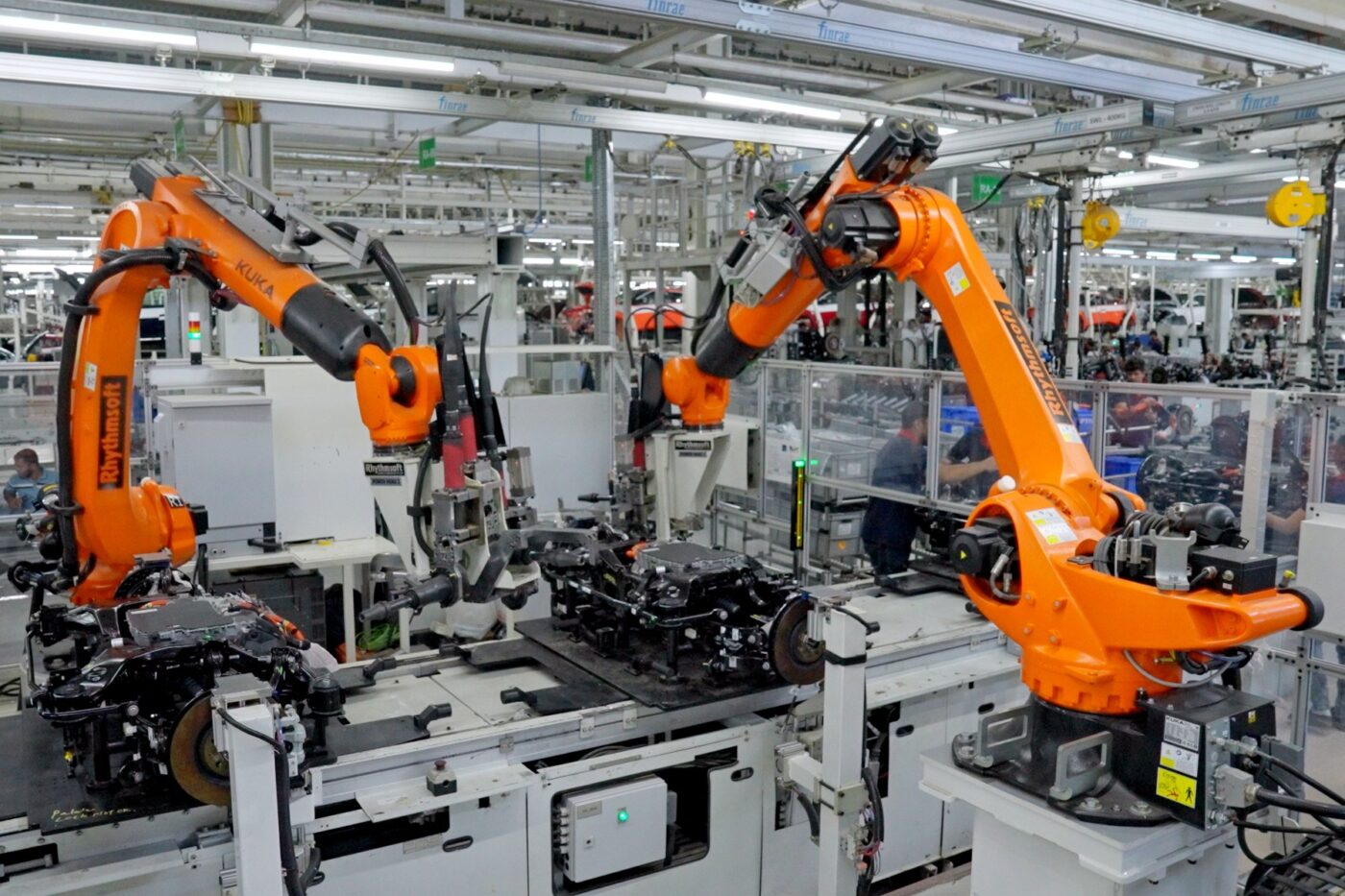

The new Mahindra EV plant spans an area of 88,000 m² and runs completely on renewable energy. The company uses over 1,000 robots and multiple automated transfer systems in this facility. The new factory has over 500 robots and fully automated transfer systems in the body shop alone. Mahindra says this plant is the first of its kind in India to feature laser brazing and pixel painting technologies.

Mahindra initially plans to manufacture 90,000 EVs at the dedicated EV factory, utilising less than half the annual production capacity – 200,000 units. The company expects to reach the plant’s peak after building a comprehensive vehicle lineup between 2027 and 2029.

As for the battery assembly inside the new EV facility, Mahindra says it is one of the world’s most compact battery manufacturing lines. The company states that 98% of its operations are automated. Other highlights are zero-touch cell handling, 3D vision-enabled plate mounting, and fully automated bolt integrity. However, it does not disclose the annual production capacity.

Mahindra started building the new EV plant in July 2023 and completed it quickly in January 2024, which it claims is a new record time. The company uses this factory to build the BE 6 sub-compact SUV-coupe and the XEV 9e compact SUV-coupe and assemble their LFP batteries. It expects to start selling these dedicated EVs in the domestic market in early March. The new production facility is part of an INR 4,500 crore investment, which Mahindra utilised even for powertrain development and two product top hats (BE 6 and XEV 9e), including their software and technology.

By the end of 2026, Mahindra plans to build a lineup of five dedicated EVs, or “Born Electric Vehicles,” as the company calls them. The Indian automaker aims to enter new challenging markets like the UK and Europe with these models.

mahindra.com (factory), mahindra.com (prices)

0 Comments