Resch aims to cut battery module costs by one-third

The relatively small technology firm Resch, based in St. Stefan, Styria (Austria), has developed a battery module that, unlike typical solutions from Asian manufacturers, does not require adhesives or welding – a potential game-changer. According to the company, several automotive OEMs are currently evaluating the solution for series production.

Resch states that Asian battery manufacturers favour adhesive bonding and welding to maximise efficiency and minimise design variance, resulting in stable yet rigid units. This makes the replacement of individual defective cells nearly impossible. Resch’s approach addresses this exact issue: the family-run business began developing a new type of battery module back in 2023 – a “revolutionary concept,” said Gerald Resch, who runs the company together with his wife, Andrea Resch.

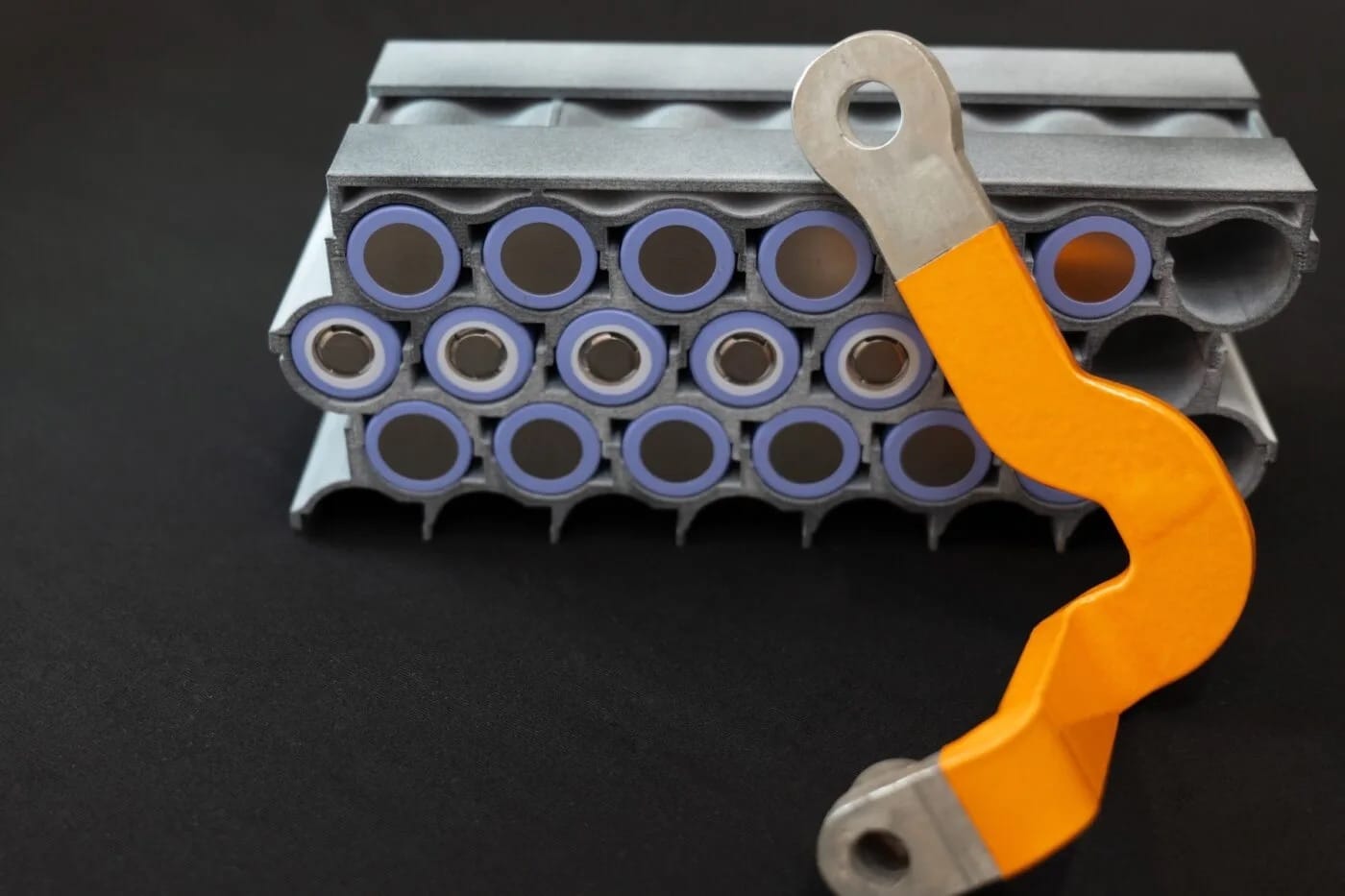

The most distinctive feature of the solution compared to conventional modules is the complete elimination of adhesives and welds. “Instead, the cells are assembled mechanically, allowing for targeted replacement of individual defective cells without needing to discard the entire module. Think of it like Lego,” explained Resch.

This design also aims to simplify recycling at the end of the battery’s life cycle. Another advantage, according to Resch, is that the new battery module is compatible with all standard cell formats.

“We’ve completely rethought the battery module – also with the goal of launching a market-ready solution from Europe,” says Gerald Resch. The principle has not only been realised technologically but, in the event of series production, is expected to reduce costs by up to one-third compared to conventional approaches.

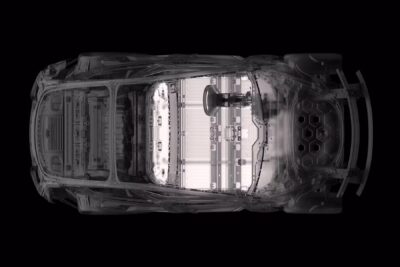

The solution may also have applications beyond the automotive sector. “Wherever electric batteries are involved – from aircraft and ships to stationary battery storage – our process can be applied,” added Resch.

The innovation is not just intended for small-scale but also for high-volume production: “The module has been designed from the ground up for fully automated manufacturing,” explained the managing director of the 25-year-old firm.

The construction process begins with a baseplate that can accommodate all common cell types. A modular carrier structure follows, allowing for variable lengths depending on cell count and power output. The assembly is completed by an end plate with integrated cooling.

Another key element is the safety concept for preventing thermal propagation – the spread of thermal runaway from one cell to adjacent ones. “When one cell overheats and ignites, it can cause a chain reaction,” the managing director explained. The new module prevents this with a folding mechanism that channels gases and particles downwards, combined with an insulating barrier that blocks heat transfer,” added Gerald Resch.

Source: Information per e-mail, automagazin.at (both in German)

0 Comments