Tesla resumes battery pack assembly in Berlin

In August, a fire broke out in the ‘Battery Pack Production’ area of Giga Berlin, Tesla’s car factory in Grünheide. No one was injured, but 512 battery cells were destroyed, equivalent to about two-thirds of a complete battery pack for a battery-electric vehicle.

Tesla has since reorganised its battery pack assembly in Grünheide and resumed production. It remains unclear whether the August fire was linked to the production changes. According to plant manager André Thierig, Tesla had previously produced around 100,000 units of an older battery pack type in Grünheide, but much has changed since then.

“We have invested heavily – in new technology and significant upgrades to plant engineering,” Thierig said during an internal event a few days ago. As a result, Grünheide has become ‘Tesla’s most highly automated battery factory worldwide.’

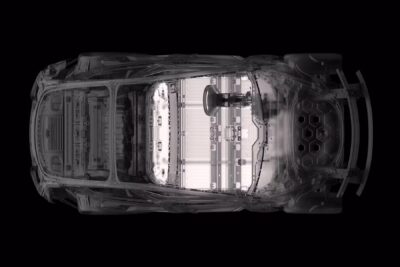

The modernised battery pack assembly introduces a key change: the battery packs now use cells manufactured by Tesla itself, specifically at its factory in Austin, Texas. Until recently, Tesla’s Grünheide plant used LFP cells from CATL and NCM cells from LG Energy Solution for the various versions of the Model Y.

This means that Model Y vehicles equipped with 4680 cells from Austin will soon be available in the European market. However, the Handelsblatt article does not specify which Model Y variant will receive these batteries.

Tesla had originally planned to produce battery cells in Grünheide but postponed its plans for series production of battery cells in Grünheide in 2022, prioritising the USA due to the prospect of substantial subsidies. For now, the focus remains on assembling battery packs, though cell production in Grünheide is still part of the long-term roadmap.

It remains unclear whether and when Tesla will implement battery cell production in Germany. While Tesla has recently advertised a position for a Battery Cell Production Manager and other roles related to cell production, this does not necessarily indicate imminent plans. According to plant manager André Thierig, CEO Elon Musk may hesitate to invest further in Brandenburg if IG Metall wins the upcoming works council election in March.

0 Comments