AESC opens Gigafactory in Sunderland

The AESC plant’s annual production capacity is initially set at 15.8 GWh, as announced by the Automotive Energy Supply Company (AESC) at the start of production. At the groundbreaking ceremony in December 2022, the expected capacity at launch was still 12 GWh. However, plans for the AESC battery factory in Sunderland have evolved several times: in the initial announcement in July 2021, production was set to begin with 9 GWh. AESC has not disclosed the extent to which production will be scaled up in later expansion phases, though recent discussions have mentioned capacities of up to 35 GWh.

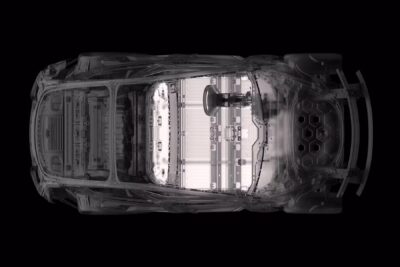

Some of the AESC battery cells produced in Sunderland will be used locally. The new gigafactory is situated near Nissan’s vehicle manufacturing plant in Sunderland, where the third generation of the Nissan Leaf is being produced. The Leaf relies on AESC cells, and the Japanese manufacturer officially commenced production of the new Leaf one day before AESC. Read our first impressions of the new Leaf here.

The new AESC plant is neither the UK’s first gigafactory nor the first AESC facility in Sunderland. AESC was originally established as Nissan’s battery division and has been producing battery cells in Sunderland since 2012 for the first-generation Leaf and the e-NV200 van, which was built in Barcelona—albeit at a much smaller scale of just 1.9 GWh. Later, Nissan sold its battery business, meaning AESC is now a partner rather than a subsidiary.

The new gigafactory features the UK’s largest cleanroom, as AESC highlighted during the launch. There, ‘the company’s cutting-edge battery cells are manufactured to the highest quality standards.’ Once fully operational, the plant is expected to employ around 1,000 people—a fourfold increase since AESC UK was founded in 2019. The company still has job vacancies and is actively recruiting.

“The launch of our new UK electric vehicle battery gigafactory represents a significant leap in battery technology. It will power the new Nissan LEAF and drive the electrification of the British car industry to a new level,” said AESC UK Plant Director Jim Marley. “Our original gigafactory was the first in Europe and the Plant 2 will anchor a resilient, globally competitive EV supply chain for the UK.”

Incidentally, on the same day as AESC, VW’s battery subsidiary PowerCo began series production of battery cells at its first gigafactory in Salzgitter. You can read all about the production of the VW unified cell in Germany here.

0 Comments