Scania and Fraunhofer electrify semi-trailers

Volkswagen subsidiary Scania made a solar cell clad trailer to power a plug-in hybrid truck and is preparing testing in Sweden. In Germany, Fraunhofer LBF was looking at semi-trucks as well and developed a lightweight high-voltage battery system for heavy-duty EVs.

The new solar supported trainer is a research project for Scania. The company is working with Swedish haulier Ernst Express, which also collaborated with Scania in trials of the world’s first electric road with overhead catenary lines.

For the new trial, Ernst Express will operate an 18-metre trailer with solar cells covering the entire area along the sides and roof of 140 square metres. The partners expect the solar panels to annually generate 14,000 kWh in Scania’s homeland with initial tests indicating “possible fuel savings of 5–10 per cent in Sweden and twice that amount in sun-rich southern Spain”.

The Swedish government’s innovation agency Vinnova funds the project. Local company Midsummer manufactures the solar panels and Uppsala University, which conducts advanced research on more efficient solar cells, and the energy company Dalakraft are also on board. Dalakraft will help to examine whether the trailer can feed electricity into the grid when the batteries are fully charged, and the truck is not in motion.

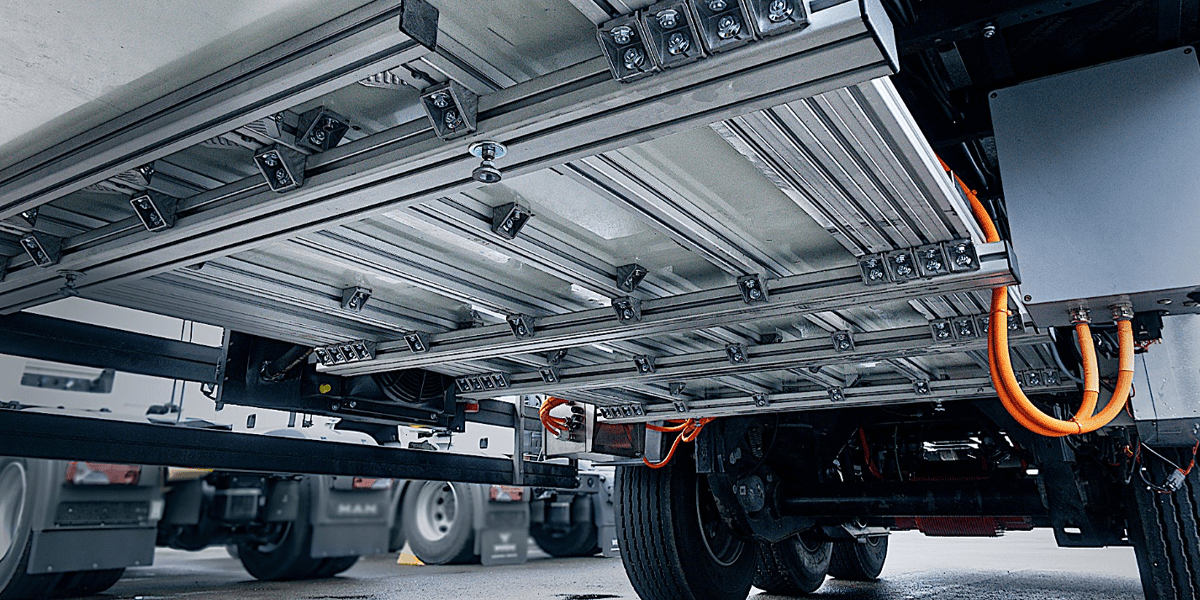

The Fraunhofer LBF project has yet to find such a real-life application. So far, research focussed on developing an energy storage unit to integrate into a semi-trailer. The unit designed by Fraunhofer LBF together with another Fraunhofer institute and the TU Darmstadt weighs just 600 kilos, including BMS and housing. 475 kilos comprise of battery material as the team integrated 10,000 cells in form factor 18650 with lithium metal oxide cathodes. The resulting energy storage has a total capacity of 100-kilowatt hours and a voltage range from 590 to 670 volts.

To combine that many cells, they developed unique current connectors using electrolytically nickel-plated cold rolled strip and then welded them to the cells that then formed modules of 240 cells each.

Adding other lightweight technologies such as sandwich structures for the casing, Fraunhofer LBF says they achieved a ratio of 0.8 between cell mass and total weight. “With such an ultra-lightweight construction solution for a high-voltage energy storage system, concepts such as the evTrailer are possible and develop perspectives for achieving the CO2 reduction targets in freight transport,” explains Rüdiger Heim, who supervised the joint research project at Fraunhofer LBF.

The researchers defined long-term use as 700,000 kilometres and determined that the discharge had to be limited to 50 per cent of the maximum possible capacity given the studied degradation. In-use applications have yet to surface.

volkswagenag.com (Scania), fraunhofer.de (in German)

0 Comments