VW Components opens battery research lab in Salzgitter

Volkswagen Group Components has opened a laboratory for cell research and development in Salzgitter, Germany. The company is thus further expanding its expertise in battery technology and taking the next step towards developing and producing its own battery cells for electromobility.

From 2025 onwards, the Volkswagen unit cell is to roll off the production line in Salzgitter. Cell development, analysis and testing will take place in a total of four laboratories. Volkswagen is investing around 70 million euros in the facilities.

The new laboratories will initially cover an area of 2,500 square metres and will enable “extensive cell testing programmes with up to 200 different analytical procedures as well as the development of new formulations”. “In the future, innovations for the cells of today and tomorrow will be created in Salzgitter,” explains Frank Blome, head of the Battery Cell and Battery System Division: “Its equipment makes the new laboratories one of the most modern facilities for cell research in Europe.”

With appropriate technologies, the cells would be put “through their paces”. For example, Salzgitter has “one of the few scanning electron microscopes in the world for detecting lithium”. Other equipment includes a highly automated test field to test cells for performance and signs of ageing during rapid charging and discharging. The test includes cells that could be charged from 5 to 80 per cent battery power within 12 minutes.

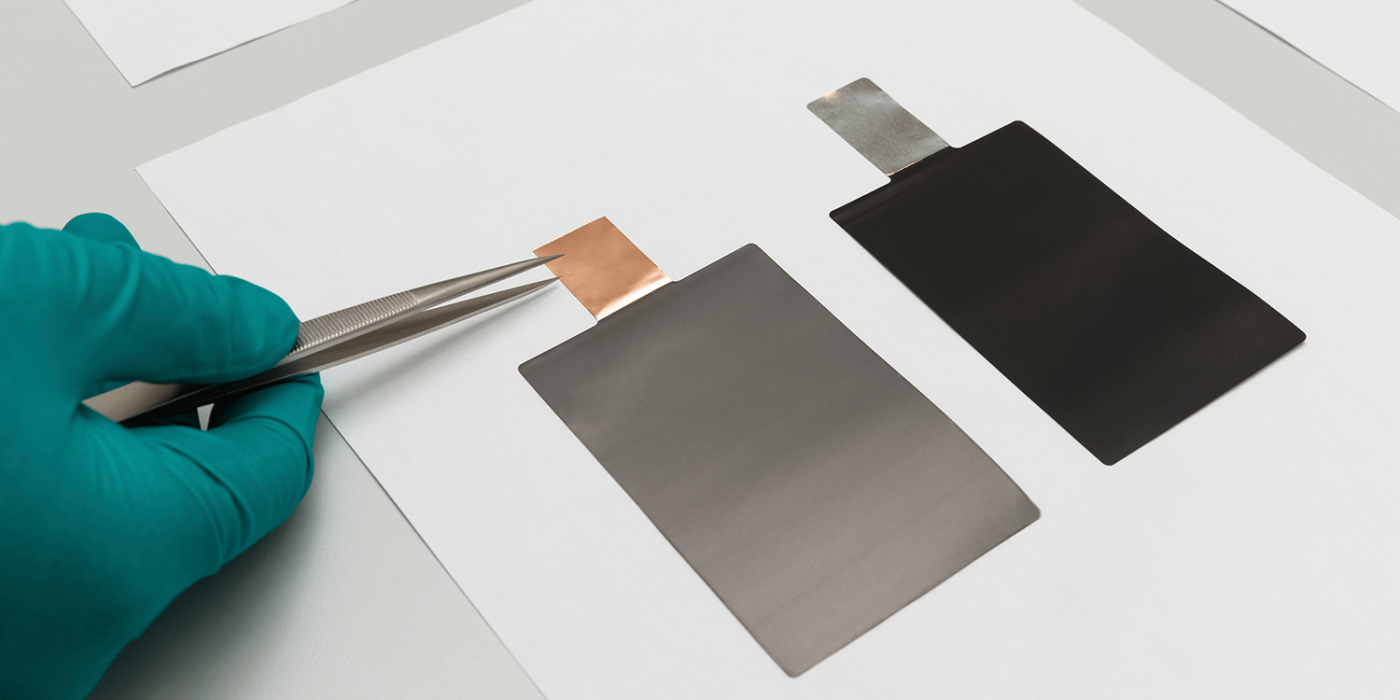

In the analytics lab, the components and raw materials of the cells are disassembled and competitive analyses and quality assurance are carried out. In the environmental and safety laboratory, cells are subjected to endurance tests in six special chambers. New test methods are also researched here. In the electrical test field, laboratory and series cells of all formats and power classes are measured electrically and tested for performance, ageing phenomena and long-term robustness.

The competence centre in Salzgitter is responsible for Group-wide material testing, release testing, quality assurance and series monitoring of cells for electric car batteries. “Of the approximately 500 employees at the Center of Excellence (CoE) Battery Cell in Salzgitter, around 160 are currently involved in cell development. By the end of 2022, the CoE is expected to grow to more than 1000 employees, including around 250 experts for research, analysis and development of suitable cell materials and formats,” VW elaborates.

“With the new, state-of-the-art laboratories, we are further expanding our development, process and production expertise for the battery cell – the heart of the battery electric vehicle. Volkswagen’s Salzgitter site demonstrates how the transformation of the German automotive industry from conventional drive systems to e-mobility can succeed,” says Thomas Schmall, Group Board Member for Technology at Volkswagen AG and Chairman of the Board of Management of Volkswagen Group Components, who is responsible for the Battery and Charging Technology Roadmap across all brands in the Group. The roadmap was presented at the ‘Power Day‘ in March 2021, and the future technologies of battery and charging were again brought into focus as key areas of the Group’s ‘New Auto’ strategy in July.

0 Comments