£12 million to boost British battery material production through science

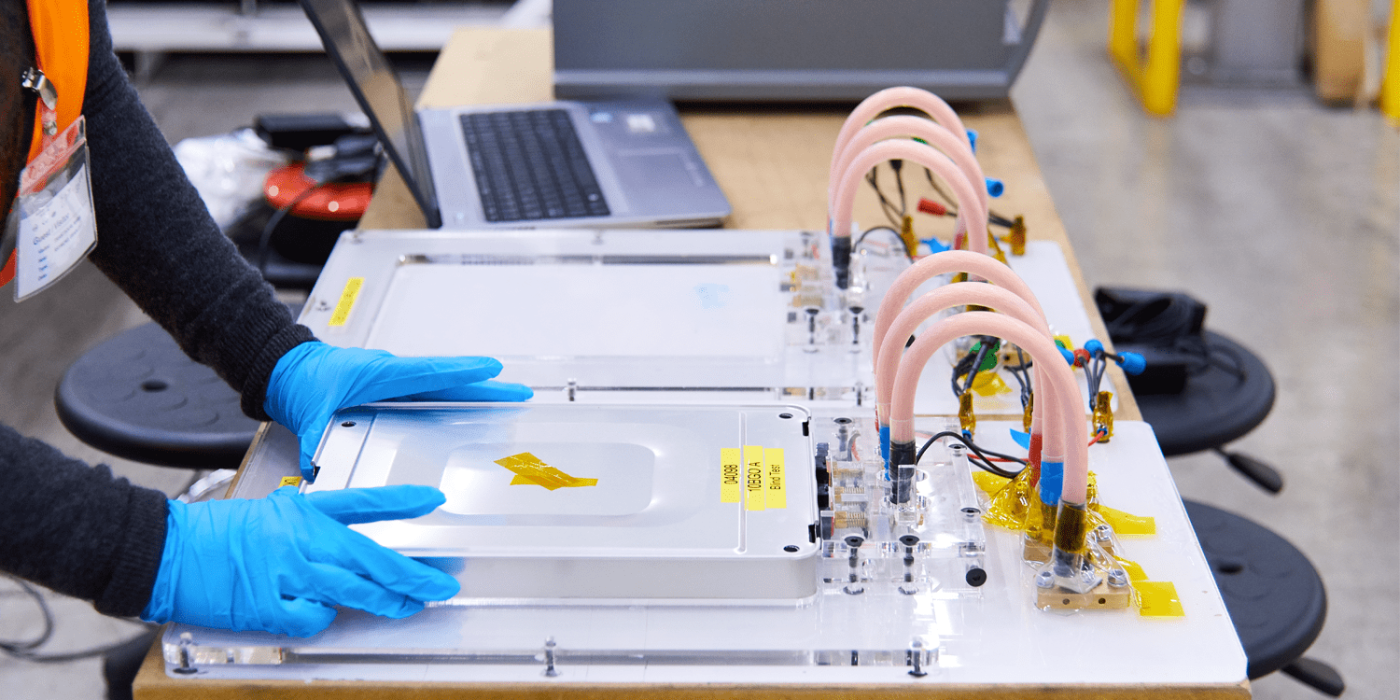

The University of Warwick expects the Advanced Materials Battery Industrialisation Centre (AMBIC) will bridge the gap between academic research and battery production. It will focus on how batteries can be made to work more efficiently, as well as on equipment and skills development.

The capital is equivalent to nearly 14 million euros or over 15 million dollars. It comes through the Faraday Battery Challenge to the High Value Manufacturing Catapult at Warwick Manufacturing Group (WMG) and CPI at NETPark (North East Technology Park) in County Durham.

The funds are part of a broader investment strategy by the Faraday Battery Challenge and the WMG to ramp up Britain’s domestic battery supply chain.

The British government committed £211 million for battery research and innovation through the Faraday Challenge in 2022 after funding the initiative as early as 2017, with the total budget now amounting to £541 million.

This funding, as well as today’s turn to academia, may also be set against the background of current British battery activities that have reached a near standstill. While Nissan recently agreed to build a third battery factory, this will primarily supply the carmaker’s EVs. (The University of Warwick worked with Nissan on batteries in 2020.) At the same time, another advance for a gigascale factory underway by Britishvolt has run into nothing but difficulty. The new owner Recharge Industries, reportedly faces legal action that could lead to bankruptcy.

However, Warwick Uni and the WMG initially also worked with Britishvolt to develop battery cell technologies and accelerate the route to market. Following a first project, the company and WMG were to embark on a two-year programme in June 2022.

Today’s communication makes no mention of these plans.

Britishvolt was also working with the UK Battery Industrialisation Centre (UKBIC) to further its cells with high nickel content, as reported as was Amte Power.

Sure enough, the WMG also collaborates with UKBIC and said today that this was to create a more resilient supply chain.

UKBIC is a government-funded research and manufacturing scale-up facility to support the British industry. The centre is located outside Coventry in Warwickshire County.

Thomas Bartlett, Challenge Deputy Director for the Faraday Battery Challenge, said: “With AMBIC and previous investments in cell, module and pack scale-up at UKBIC and R&D in the wider ecosystem, the UK will now be in a position to support businesses from ‘powder to pack’ and from lab to commercial scales.”

He added AMBIC would “bring together two emerging regions of battery innovation and manufacturing, the North-East and Midlands, under one facility to de-risk and accelerate battery materials scale-up in the UK.”

County Durham is in North East England and just a short distance from Sunderland, Nissan’s manufacturing base in the UK.

In other news today, UKBIC has secured a further £38m in funding to upgrade the facility’s scale-up capabilities. Announced as part of the Autumn Statement, the budget builds upon the £36m already committed by Faraday Battery Challenge in May. Preparatory work on the construction of the facility is underway.

Sean Gilgunn, UKBIC’s managing director, said “The investment in the new equipment and capability will mean that many more customers will be able to use the facility seamlessly to develop battery manufacturing through to large-scale demonstration.”

warwick.ac.uk, insidermedia.com (UKBIC funding)

0 Comments