BASF and Stena join forces in recycling batteries

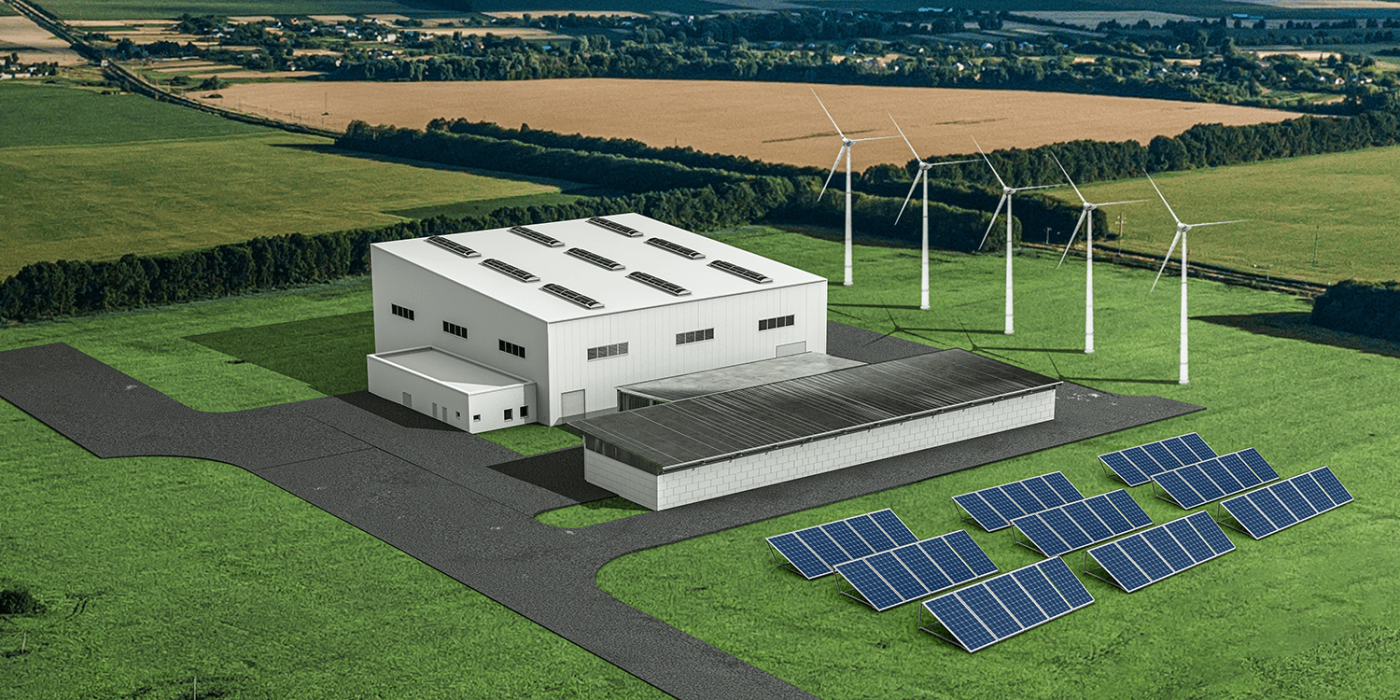

The cooperation will focus on developing improved processes to achieve high recovery rates for metals such as lithium, nickel and cobalt. Under the new agreement, Stena Recycling in Halmstad, Sweden, will collect, assess, and pre-treat end-of-life lithium-ion batteries and scrap from battery production to produce black mass. BASF will further process and refine the latter in its prototype metal refinery in Schwarzheide, Germany.

The so-called black mass is produced in the first phase of battery recycling. After the mechanical treatment of the battery (i.e. dismantling and shredding), components such as plastics and aluminium can be filtered out. The black mass remains, containing large quantities of the battery’s active materials – such as lithium, nickel, cobalt and manganese. In what is called a hydrometallurgical process, water and chemicals are used to separate this mass back into individual materials (which are then used to produce new cathodes).

The electrification of society has only just begun, and we want to boost a circular approach to battery production,” says Marcus Martinsson, Product Area Manager Batteries at Stena Recycling Group. “Cooperation between industry actors will be essential for a successful green transition. With this agreement in place, Stena Recycling strengthens its position as one of the leading recycling partners in Europe, to both battery manufacturers and the vehicle industry.”

“By entering into a cooperation with Stena Recycling, we are strengthening BASF’s ability to offer a broadened battery collection network with a strong partner in the Scandinavian countries so that we can expand our offer for individual and closed loop solutions to battery producers and electric vehicle manufacturers in Europe,” says Daniel Schönfelder, President of BASF’s Catalysts division, who is also responsible for the company’s battery materials and battery recycling business. “This is an important step towards a circular economy for the European electric vehicle battery market.”

Stena Recycling and BASF intend to transfer their model to BASF’s planned commercial-scale metal refinery for battery recycling at a later stage. The annual processing capacity is expected to be 15,000 tonnes.

0 Comments