‘BATTwin’ research project on sustainable battery production

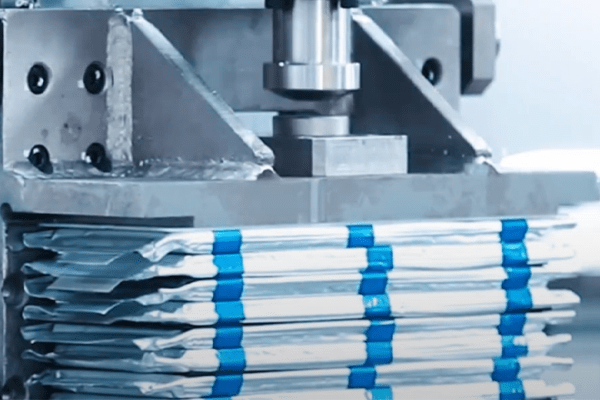

The team led by the Polytechnic University of Milan (Italy) aims to develop digital twins of battery factories by the end of the project in May 2027. The aim is to reduce waste, energy requirements and emissions from cell production in order to make the manufacture of batteries more efficient and environmentally friendly. The declared goal is a European “zero-defect gigafactory”.

A central topic – how to avoid the production of faulty battery cells – is being investigated in Oldenburg, specifically by the team led by computer scientist Andreas Rauh from the ‘Distributed Control in Networked Systems’ department. In order to reduce the current reject rate of around ten per cent, the researchers are developing models of the individual stages of cell production based on physical processes and coupling these with data-driven processes.

According to the university’s press release, the aim is to determine how well battery production lines are working and to predict possible errors. To this end, the models collect and manage process control data and characterise uncertainties in the manufacturing process that influence quality. “This makes it possible to gradually improve the production process and optimise important control variables not only during the design phase, but also during operation,” says the university.

Rauh and his team are building a laboratory infrastructure in parallel to this project in order to be able to experimentally test the charging and discharging processes of individual battery cells on their own test bench. This device will allow the team to test their own models. “These should enable conclusions to be drawn about the battery open-circuit voltage, for example, from measurements that are directly available during operation, and from this derive how good the condition of individual battery cells is and how quickly their ageing is progressing,” explains the press release.

BATTwin (“Flexible and scalable digital-twin platform for enhanced production efficiency and yield in battery cell production lines”) is being funded by the EU’s Horizon Europe programme with around 6.4 million euros. Around 630,000 euros of this will go to the University of Oldenburg. Six universities and research institutions as well as ten partners from industry across Europe are involved in the project, including plant manufacturer Comau and battery manufacturer Verkor.

0 Comments