BMW integrates Solid Powers’ solid-state batteries into i7

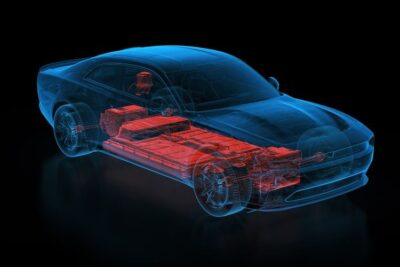

BMW and Solid Power have been working together on solid-state batteries for years. The beginnings of their partnership date back to 2016. Things turned serious three years ago when both sides signed a technology transfer agreement. One direct result is now the testing of solid-state cells in a BMW test car. The solid power cells with their sulphide-based electrolyte are fully integrated into a battery pack, which the BMW Group hopes will provide further important findings in the test programme in the coming months. In particular, the partners want to investigate the management of cell expansion. The partners are also focussing on how the operating pressure can be controlled and how the temperature boundary conditions can be adjusted.

BMW does not go into much more detail, but does state that the concept battery integrated in the test vehicle “combines proven Gen5 construction principles (prismatic cells in modules) with new, innovative module concepts for integrating ASSB cells from Solid Power.” Gen5 refers to the prismatic cells that are currently installed in modules in BMW electric cars. These are not yet the future round cells of the new class, which are labelled Gen6 in the company. The test car is also already tried and tested: BMW presented the i7 as its new electric flagship in April 2022.

BMW and Solid Power see “a higher energy density compared to current battery technologies” as a potential advantage of the solid-state battery. The Munich-based company emphasises that although the innovative cells are being developed and manufactured by Solid Power, this is being done in close collaboration with experts from the BMW Group. In the partners’ view, the potential is there, but there will be no rapid series production: “Further development steps are required to implement ASSB technology in a competitive overall storage system,” according to an accompanying press release.

Martin Schuster, Vice President Battery Cell and Cell Module at the BMW Group, comments: “Our BMW i7 ASSB test vehicle on the road is a perfect example of the BMW Group’s technology-open mindset. We are continuously advancing the development of new battery cell technologies and are constantly expanding our know-how with valuable partners such as Solid Power.”

“Solid Power is extremely proud that our partnership with BMW has resulted in the first demonstration of truly all-solid-state battery cells in a vehicle,” added John Van Scoter, President and Chief Executive Officer of Solid Power. “We believe in the promise of ASSB’s and continue to drive innovation of our sulfide electrolyte in support of that future for EV’s.”

Solid Power produced and delivered the first A-samples of the solid-state cells to BMW at the end of 2023. This delivery marked the start of the formal automotive qualification process. Even then, it was said that BMW wanted to install the cells in a first demonstration vehicle before the middle of the current decade – this has now been achieved. At the same time, BMW is setting up a prototype line for solid-state battery cells based on the solid-power designs at its Cell Manufacturing Competence Centre in Parsdorf near Munich. This is made possible by a research and development licence granted to BMW by the US company.

Solid Power was founded in 2011 as a spin-off from the University of Colorado. Today, the company is one of the world’s most promising developers of solid-state battery cells. In the summer of 2022, the U.S. company announced that it had completed the installation of its pilot production line and was now able to supply cells for qualification tests to its investors and customers. In addition to BMW, SK On and Ford are among the most prominent partners. The pilot line will automatically produce all-solid-state battery cells using the company’s own sulphide-based solid electrolyte material. At full capacity, the pilot line is expected to be able to produce around 15,000 cells per year. Series production is scheduled to start at a later date.

The company announced details of its solid-state battery platform in 2021. Conventional NMC cathodes are used, meaning that production does not have to be switched. In combination with a silicon anode and a solid electrolyte, Solid Power wants to build a cell with a gravimetric energy density of 390 Wh/kg. If a lithium metal anode is used instead of the silicon anode, the cell (still with an NCM-811 cathode) achieves an energy density of 440 Wh/kg.

0 Comments