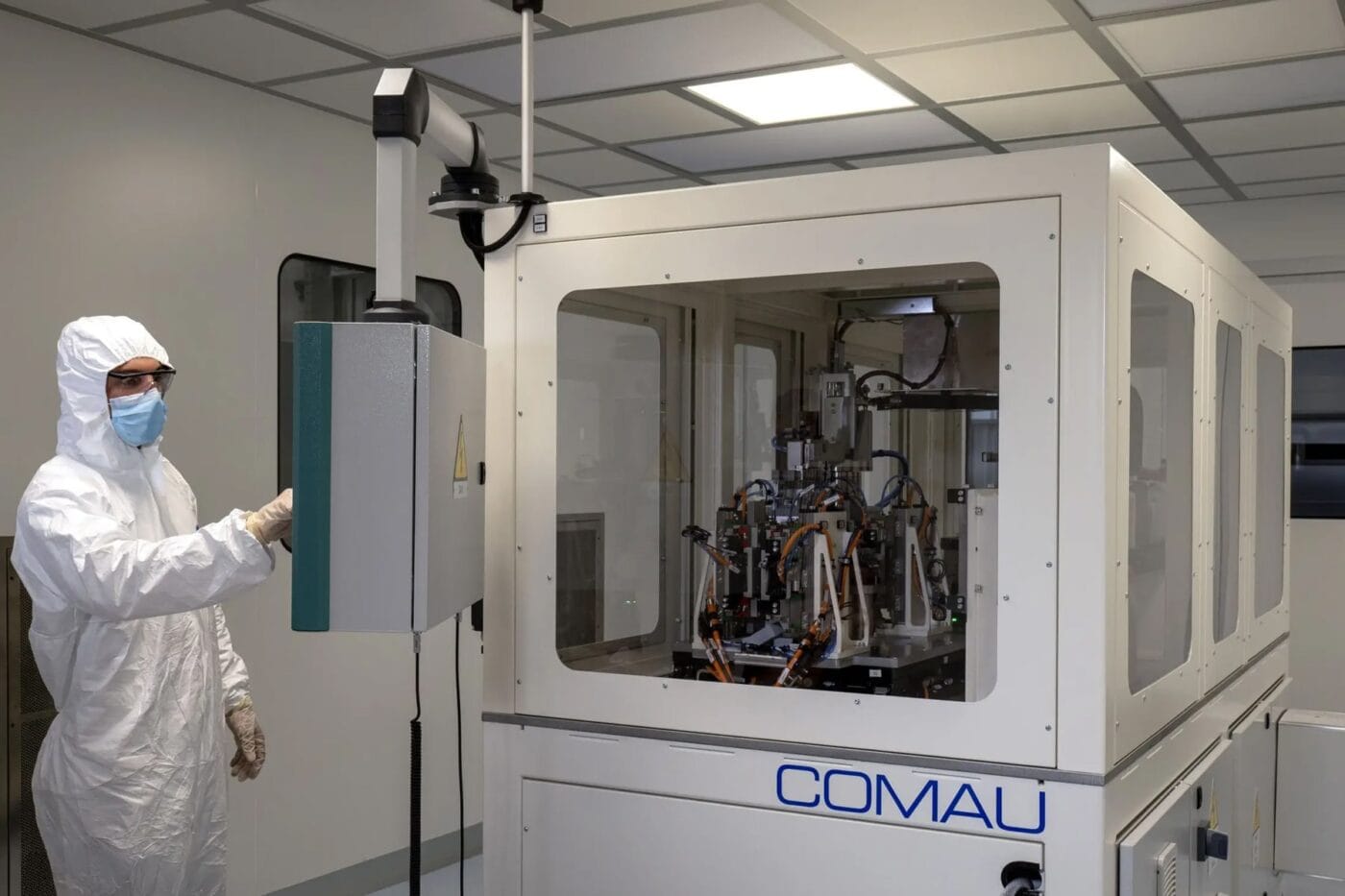

Comau inaugurates dry room laboratory

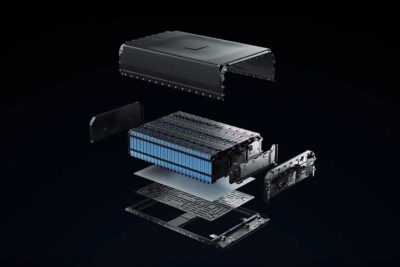

With the dry room, Comau is strengthening its expertise in the field of end-to-end battery solutions – and not just for current-generation batteries, but above all with a view to innovative next-generation batteries. The Italians have explicitly stated that one of their next milestones is to provide access to solid-state technologies. The new drying room, in which Comau says it has invested almost one million euros, is intended to accelerate development and commercialisation.

The laboratory has three so-called proto-test stations (two with a dew point of -40 °C and one with -50 °C). The room’s automation equipment includes the Comau Racer 5 Sensitive Environments robot. The facility is open to customers, universities and associations, in addition to Comau’s Global Competence Centre team, which currently consists of more than 40 engineers.

CEO Pietro Gorlier emphasised that Comau continues to invest in research and development in various industrial sectors, including electromobility: “As recently demonstrated by the launch of a new full line of Cobots and AMRs, as well as welding technologies, Comau continues to invest in research and development across all of its strategic sectors, including e-Mobility.” The new dry room will allow the company to “experiment with new battery cell formats and materials in a controlled, humidity-free environment, reflects our ongoing commitment to advancing industrial innovation while also reinforcing our presence and investments in Italy.”

Comau announced a cooperation with the US company Intecells in the battery sector only around a month ago. Together, the duo is working on the integration of cold plasma into industrial processes for the production of battery cells. The aim is to make solvents and binders superfluous in cell production in the future.

Additionally, Comau presented a platform for small-scale cell moulding at the beginning of June. Despite the withdrawal of Stellantis as a shareholder in January, Comau also remains active in European battery projects such as BATTwin and the Reinforce recycling project.

0 Comments