PowerCo starts unified cell production in Salzgitter

In the first phase, Salzgitter will establish an annual production capacity of up to 20 GWh, which can be expanded to 40 GWh if required, as PowerCo announced at the start of series production. These figures were essentially already known. However, given that the VW Group is apparently scaling back further investments in PowerCo, it is significant that the planned capacities have now been reaffirmed.

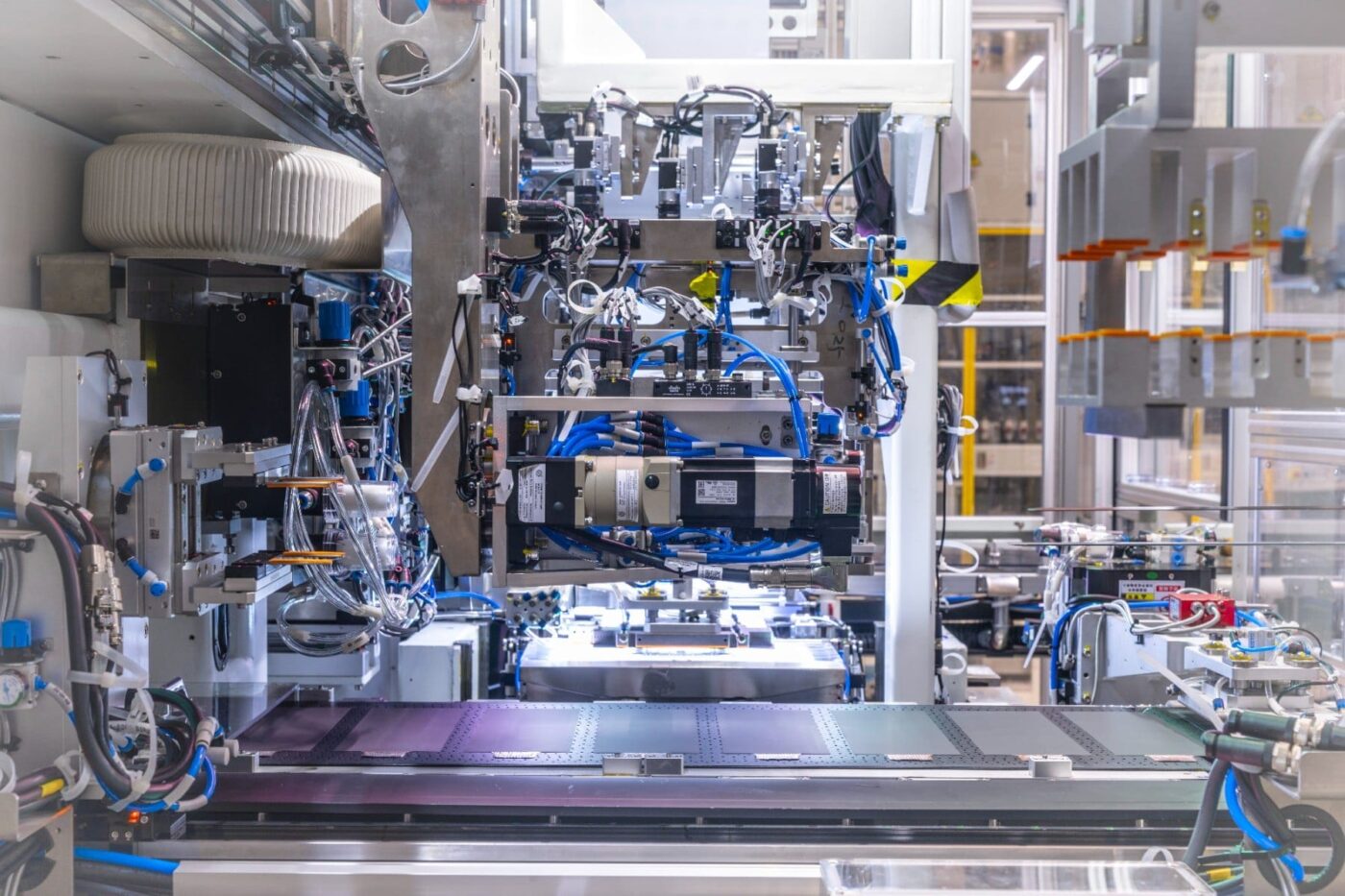

Herbert Diess and then German Chancellor Olaf Scholz laid the foundation stone for the “SalzGiga” in July 2022. The hall constructed since then is approximately 600 metres long, 350 metres wide, and 30 metres high. The 69,000 square metre area is equivalent to around ten football pitches. The first expansion stage of 20 GWh is expected to produce battery cells for around 250,000 electric vehicles, naturally depending on the battery size of the cars.

The unified cells now being mass-produced in Salzgitter are described by the VW division as a ‘milestone for the Volkswagen Group and the European battery industry.’ Not only is production taking place in Europe, but the cells were also designed and developed locally. This sets it apart from, for example, the CATL factory near the Erfurter Kreuz, where the Chinese market leader relies on technologies developed in China.

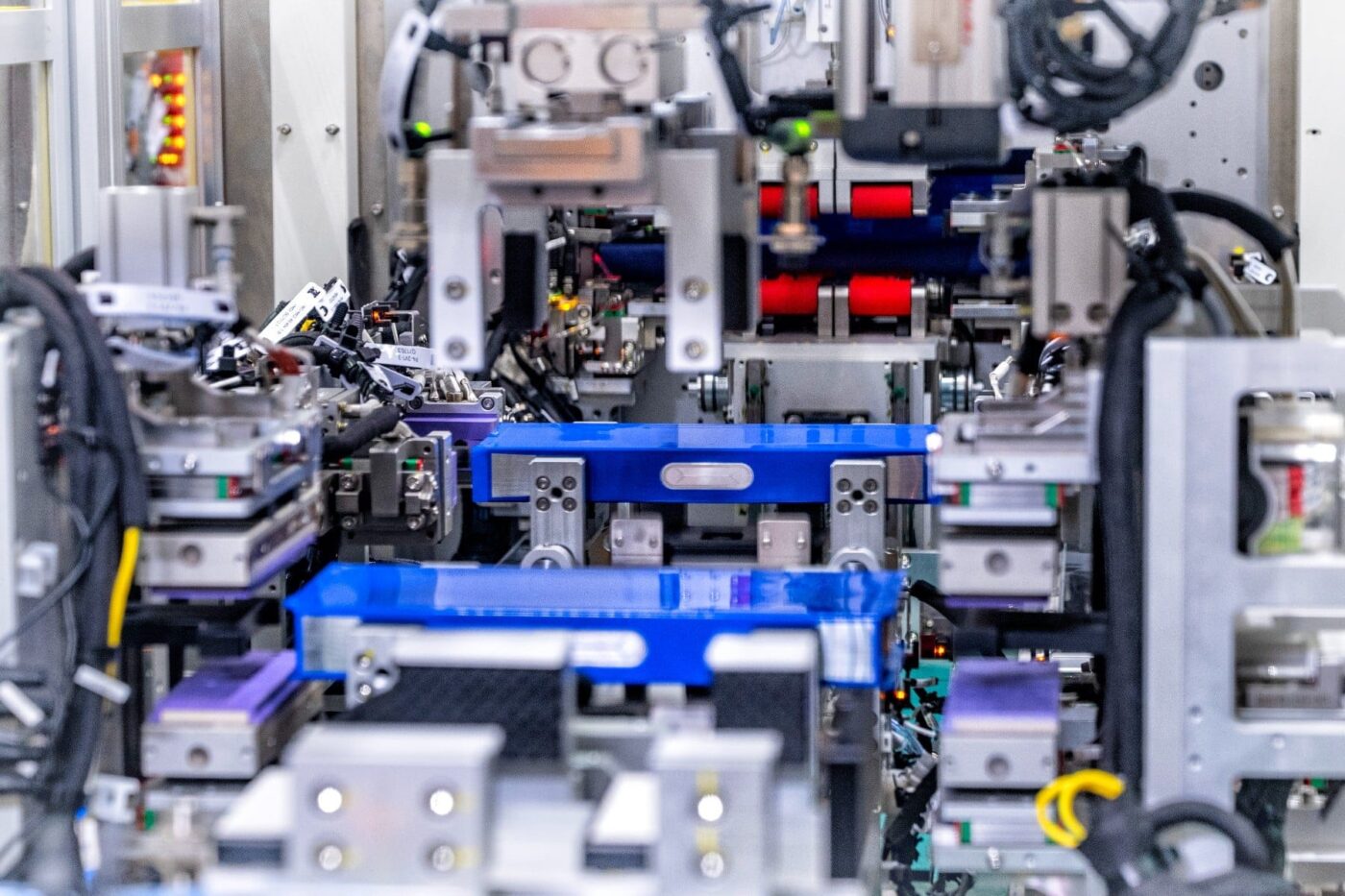

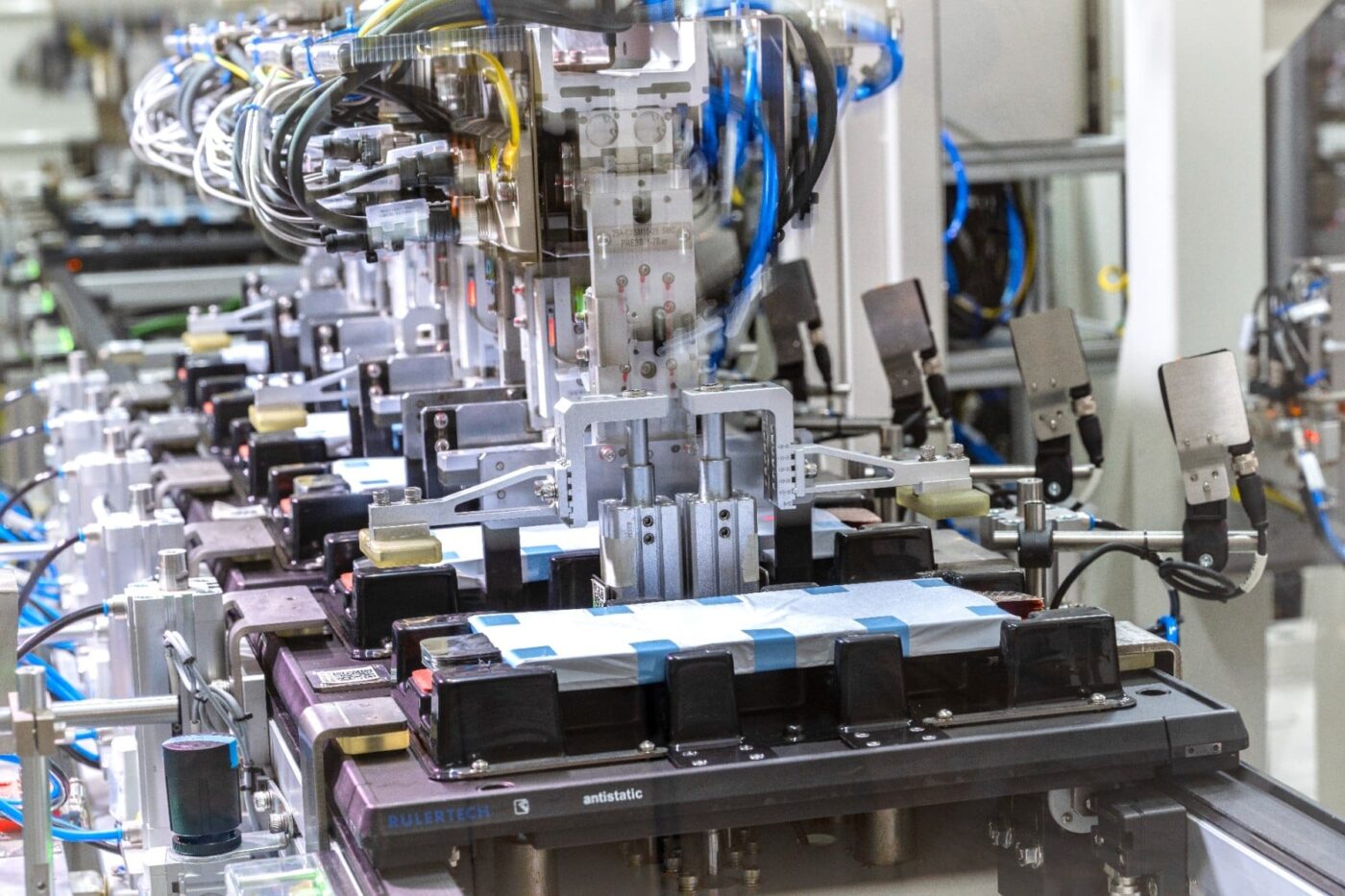

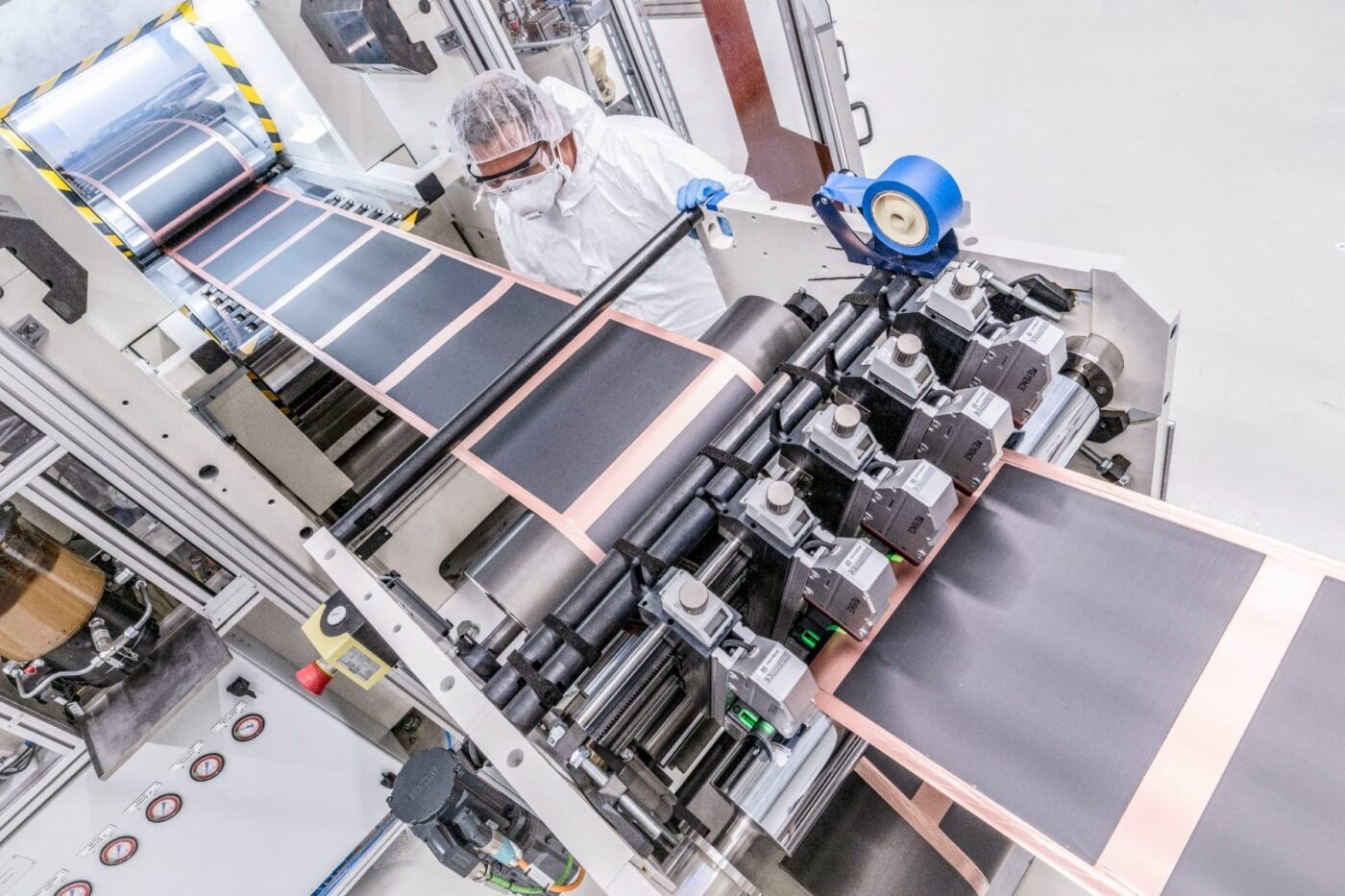

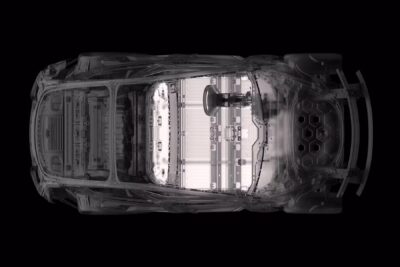

The unified cell dates back to Herbert Diess’ tenure as CEO of the Volkswagen Group. It is a prismatic battery cell with a standardised, uniform size—specifically, 256 x 24.8 x 106 millimetres. “The standardised cell architecture enables worldwide use across all brands and regions and offers economies of scale, cost advantages and technological flexibility,” PowerCo stated. However, to adapt the cell to the requirements of different vehicles—ranging from small electric cars to large luxury SUVs or Porsche sports cars—the standardised format can be filled with various cell chemistries, including future solid-state cells. This is already being implemented in the first series application of the unified cell: the Electric Urban Car Family, including the VW ID. Polo, will be offered with both LFP and NMC cells.

This flexibility, based on the standardised architecture, is also intended to ensure that the insights gained in Salzgitter can be utilised in PowerCo’s other factories. Salzgitter will serve as the lead plant for subsequent projects in Valencia (Spain) and St. Thomas (Canada), all of which are based on PowerCo’s standard factory concept.

VW partner Gotion also produces the unified cell

In Salzgitter, PowerCo has commenced production of an NMC cell, which the company claims is ‘one of the most powerful battery cells in the volume segment.’ Specifically, the energy density is expected to be around 10 per cent higher than that of currently used NMC cells. Additionally, the cell’s design is optimised for the Cell-to-Pack concept of upcoming VW electric models. “More variants will follow, for example the PowerCo Unified Cell with LFP technology,” PowerCo announces, though no further details are provided.

However, even with production in Salzgitter and the two additional PowerCo plants currently under construction, the VW Group will not fully meet its demand for unified cells—PowerCo will produce only about half of the required volume in-house. The remainder will be sourced from external suppliers, which also manufacture battery cells in the ‘unified cell’ format for Wolfsburg. Among these is the Chinese manufacturer Gotion High-Tech, in which VW holds a stake. Gotion has recently started producing its unified cells—apparently an LFP cell with a capacity of 91.5 Ah and an energy density of 190 Wh/kg, as well as an NMC cell with 115.8 Ah and 265 Wh/kg. In other words, even if Salzgitter cannot directly supply the unified cells required for small electric vehicles during the ramp-up phase, the supply chain for both cell chemistries is secured—there is no risky single-sourcing. Since Gotion has already begun production, PowerCo’s recent announcement refers only to the first unified cells ‘made in Europe’—not the first overall.

“The PowerCo Gigafactory in Salzgitter sends a strong technological signal for Europe and serves as a cornerstone on our path to becoming a global automotive tech leader,” said Oliver Blume, CEO of the Volkswagen Group. “We are the first European carmaker to establish our own battery cell development and production. This step strengthens our position and independence in the global competition.”

Thomas Schmall, Group Board Member for Technology, emphasised: “With PowerCo, we are consistently expanding our know-how in battery technology. In combination with the new battery system, the Unified Cell “made in Salzgitter” brings a real technological leap for our customers. This puts us in the driver’s seat when it comes to a key technology for e-mobility.”

“In just three years, we have built an entirely new company, developed a competitive product, and completed a cell factory along with its upstream supply chain. At the same time, we are already constructing the next cell factories in Spain and Canada,” says PowerCo CEO Frank Blome. “In short: we deliver. This achievement is the result of an outstanding team effort by many colleagues at PowerCo and Volkswagen – and I’m deeply grateful for that.”

The quotes from Schmall and Blome are particularly noteworthy, as internal resistance within VW to in-house cell production has reportedly increased recently. Given the Group’s declining profits, the Porsche and Piëch families in particular have questioned the rationale behind the high investments in cell production. The fact that the responsible managers are now emphasising the technological lead and competitiveness of the product is therefore aimed not only at external audiences, but also at internal critics.

Source: Information via email, volkswagen-group.com

0 Comments