Dresden researchers to improve battery cell electrodes

Researchers at the Dresden ExcellBattMat Center at the Fraunhofer IWS want to contribute key components to the large-scale “Research Production Battery Cell” project in Münster. The research object is electrodes made of silicon or lithium layers.

Background: German scientists want to pool their expertise at various locations and develop new batteries for electric cars, among other things, in the “Battery Research Factory” roof concept, which can store at least 70 per cent more energy than conventional lithium-ion solutions with the same volume. We are talking about electric vehicles that are capable of driving up to 700 kilometres with one battery charge.

The overriding goal is to create the basis for Germany’s large-scale production of battery cells. To this end, scientists from Dresden are now presenting their three-year research contribution. Since this month, they have been working on electrodes consisting of wafer-thin Si or Li layers to achieve high energy densities. According to their statements, they act as a high-tech forge for new materials within the “Battery Research Factory”, which unites numerous battery funding activities of the Federal Ministry of Education and Research under one roof.

The Dresden project is entitled KaSiLi (Structural Mechanical Cathode Adaptation for Silicon and Lithium Materials) and is also embedded in the BMBF-funded ExcellBattMat competence cluster for battery materials. According to an accompanying press release, the research team wants to have functional demonstrators ready by 2022. According to an accompanying press release, the new battery design will flow into the battery cell research production project in Münster.

But what exactly is being researched? The answer: New materials, design principles and processing technologies for the electrodes of battery cells are to be developed in Dresden. Today, the anode in a lithium-ion battery usually consists of a copper conductor a few micrometres thick, covered with a graphite layer about 100 micrometres thick, explains the research team. This graphite layer is to be replaced by much thinner layers of silicone or lithium. In the laboratory, this is already working quite well and is already providing more energy storage capacity. “Today’s lithium-ion batteries have an energy density of around 240-watt hours per kilogram or up to 670-watt hours per litre,” says Stefan Kaskel, professor of chemistry at Dresden Technical University and head of both the ExcellBattMat centre in Dresden and the KaSiLi project. Their aim, specifically, is to achieve “well over 1,000-watt hours per litre.”

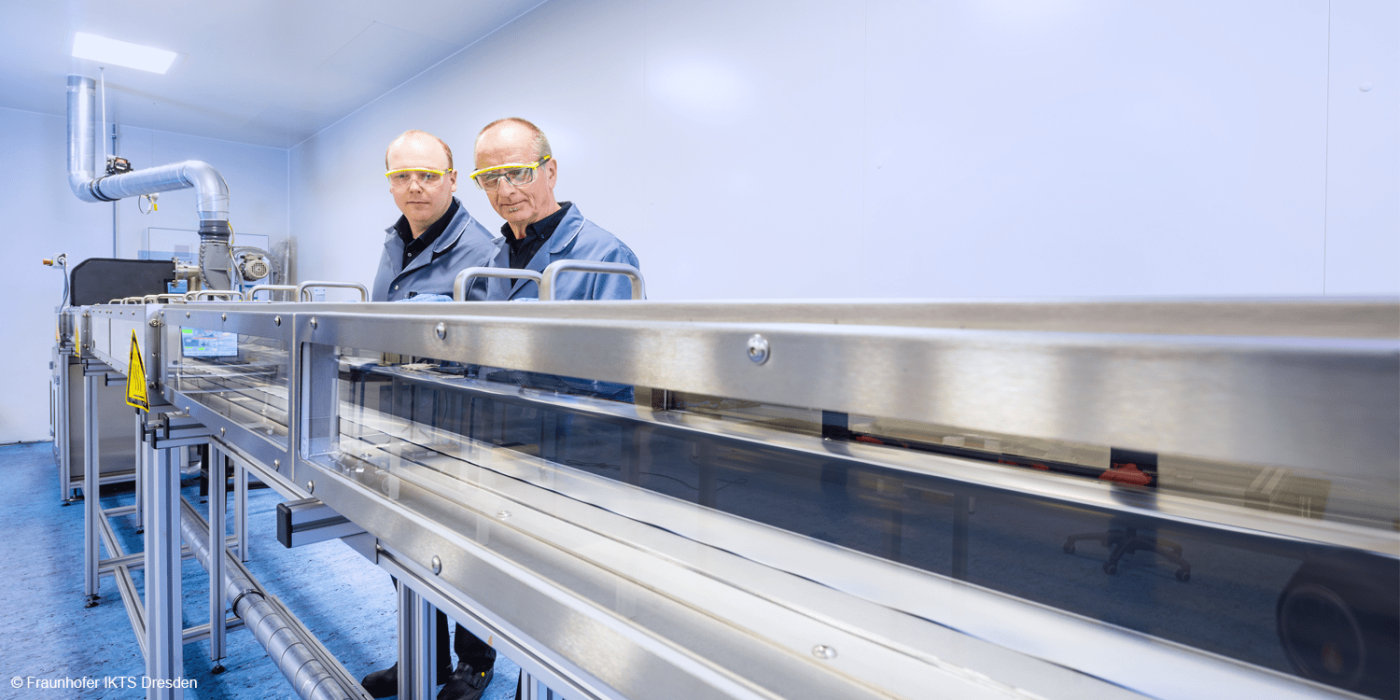

Several institutions are involved in the project: The Fraunhofer IWS contributes its experience in thin-film technology. The Fraunhofer IKTS deals with oxide cathode technology and its scaling. The nanoelectronics laboratory NaMLab at the Technical University of Dresden (TUD) uses special spectroscopy equipment to investigate the newly designed anodes. The Dresden Leibniz Institute for Solid State and Materials Research focuses on the structural analysis of electrode layers. The TUD Chairs of Inorganic Chemistry and Inorganic Non-Metallic Materials are responsible for the preliminary research for new electrode structures. Besides, the Dresden facilities cooperate with the three other ExcellBattMat centres in Germany in Münster, Munich and Ulm.

0 Comments