BMW launches battery production for iX & i4

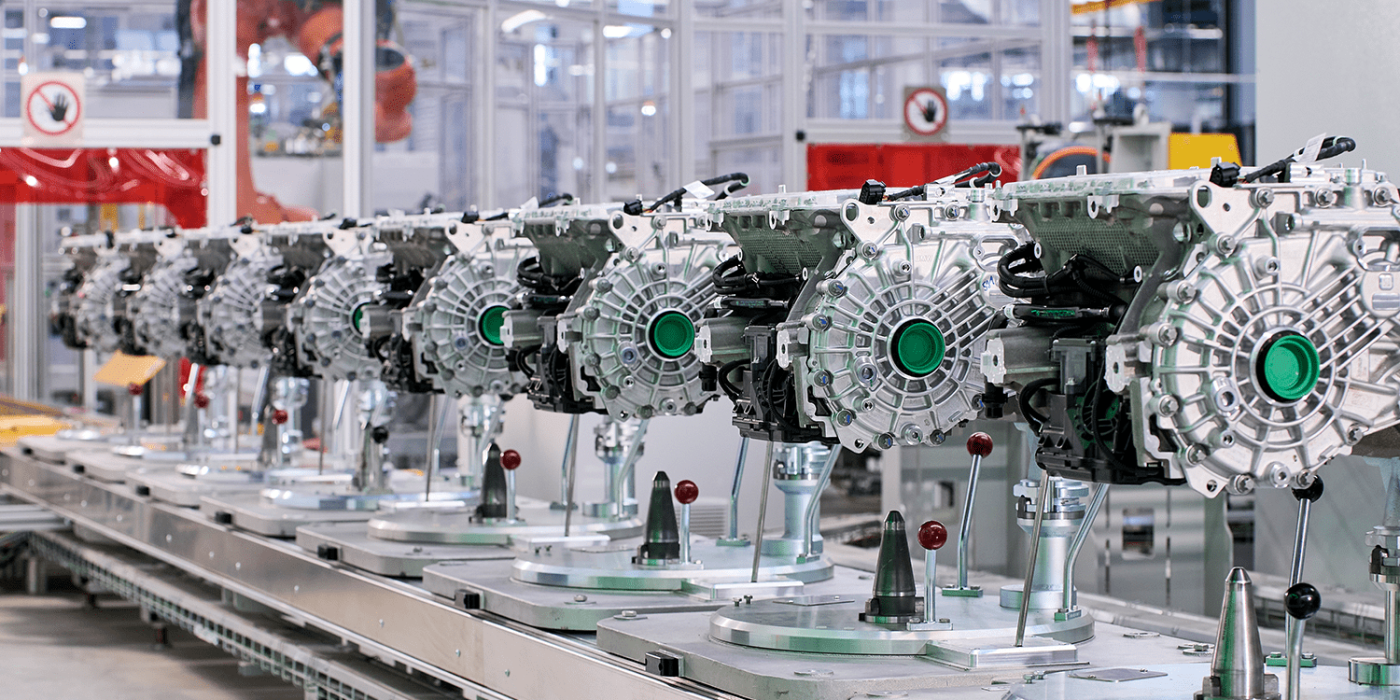

BMW has started manufacturing the high-voltage batteries and battery modules used in the iX and i4 at the Competence Centre for E-Drive Production in Dingolfing. The capacity for the production of the electric motors at the site has also been increased.

The batteries for the iX will remain in Dingolfing, where production of the electric SUV is scheduled to start “shortly”. The electric sedan i4 is to be built at the plant in Munich from autumn. BMW does not give any further details on the batteries assembled in Dingolfing in the press release. What is known, however, is that the cells are painted at the Regensburg plant before being assembled into modules and ready-to-install battery packs. According to BMW, painting the cells increases the mechanical robustness and thermal conductivity of the battery cell.

The cells, which are assembled into modules and packs in Dingolfing, were developed at the Battery Cell Competence Centre, which the company opened in Munich in November 2019. The cells can also be manufactured there on a prototype scale, but the actual large-scale production will be handled by CATL and Samsung SDI.

At the same time, capacities for the production of the fifth-generation electric motor will be increased. This generation of motors has been produced for the iX3 in Dingolfing since 2020 and is then transported to the vehicle plant in Shenyang in China. In future, motors from this modular system will also be used in the iX and i4 and installed in the vehicles in Germany.

According to the Munich-based company’s statement, the competence centre for electric drive production now covers 125,000 square metres and currently employs more than 1,400 people. “We are increasing capacity at existing drive train production locations – like here in Dingolfing – and developing capabilities at others – like recently in Regensburg and Leipzig,” says Michael Nikolaides, Head of Production Engines and E-Drives. “We are growing our staff for e-drive production almost exclusively through personnel restructuring.” By the end of 2021, around 1,900 employees are expected to be working in electric drive production in Dingolfing.

This means that electric drive production has grown faster than BMW itself expected: When the competence centre was opened in July 2020, BMW had still stated that the area was to grow to 80,000 square metres by 2022. Electric drive production in Dingolfing had already begun in 2015: at that time, the drive for the i3 was assembled on 8,000 square metres.

BMW will initially offer the iX in two variants. The iX xDrive 40 will have a system output of 240 kW from its two electric motors and a battery with “a gross energy content of more than 70 kWh”. The iX xDrive 50 has an output of 370 kW and a battery with a gross energy content of “more than 100 kWh”. In the case of the i4, only the top model’s output of 390 kW has been officially confirmed so far, and the battery is said to come to “around 80 kWh”.

0 Comments