Johnson Matthey & OnTo launch recycling cooperation

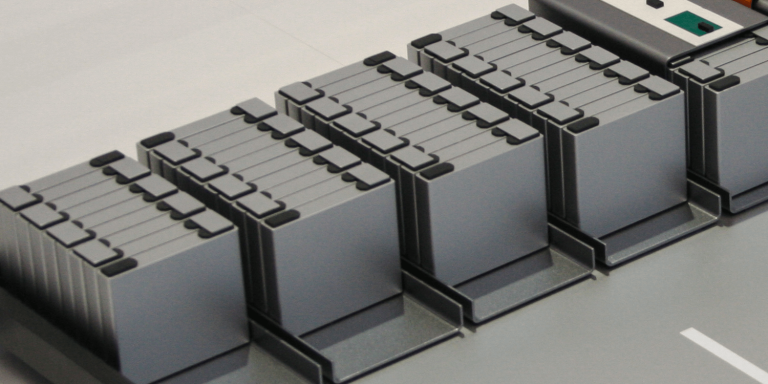

The British chemical company Johnson Matthey is cooperating with OnTo Technology, a developer of battery recycling solutions. The aim of the partnership is to further develop OnTo’s patented recycling process ‘Cathode Healing’. The focus is on battery waste that is already generated during production.

The collaboration between Johnson Matthey and OnTo also involves the UK Battery Industrialisation Centre (UKBIC), which opened in Coventry in July. The partners also receive financial support from the UK government. At the heart of OnTo’s approach is so-called “direct cathode recycling”, in the course of which “valuable electrode coatings can be recovered from battery production waste”. The patented process is said to be able to recycle the coating material in such a way that it is suitable for use in the manufacture of new batteries.

“We are excited to be working with Johnson Matthey and UKBIC to unlock the potential of direct cathode recycling,” said Steven Sloop, president of OnTo Technology. He says he is confident that with the combined capabilities of all three players, it will be possible to “develop a viable process that represents a compelling economic proposition for battery manufacturers”.

Johnson Matthey, meanwhile, cites a Bloomberg study that says production of lithium-ion batteries for electric vehicles in Europe is expected to increase more than tenfold from 82 GWh/year to 934 GWh/year in 2030. As the scrap rate in production is typically five to ten per cent, recycling key raw materials from production waste represents a significant opportunity to drive efficient and circular manufacturing technologies towards a net-zero future, the group says.

In April this year, Johnson Matthey had already signed an agreement with Stena Recycling to develop an efficient value chain for the recycling of lithium-ion batteries and battery cell materials in Europe. The division of tasks: recycling and disposal expert Stena is currently implementing facilities and processes to extract the materials from the batteries for further refining. Chemical company Johnson Matthey will then take over this refining and is developing the necessary processes for this.

The British company is also active in the primary raw material battery market: in April, the group also announced the construction of a new factory for the production of its nickel-rich eLNO cathode materials. This will be built in Finland as part of a strategic partnership with the Finnish Minerals Group (FMG). The plant will complement production in Konin, central Poland. Parallel to the announcement of the construction of the plant in Vaasa, Finland, the chemical group also made public in the spring that it had concluded contracts for the long-term supply of raw materials for the production of battery materials with Nornickel and SQM.

0 Comments