Chalmers University is developing a battery recycling process using oxalic acid

The process makes it possible to recover 100 per cent of the aluminium and 98 per cent of the lithium from electric car batteries, according to a statement from the university. It also minimises the loss of valuable raw materials such as nickel, cobalt and manganese.

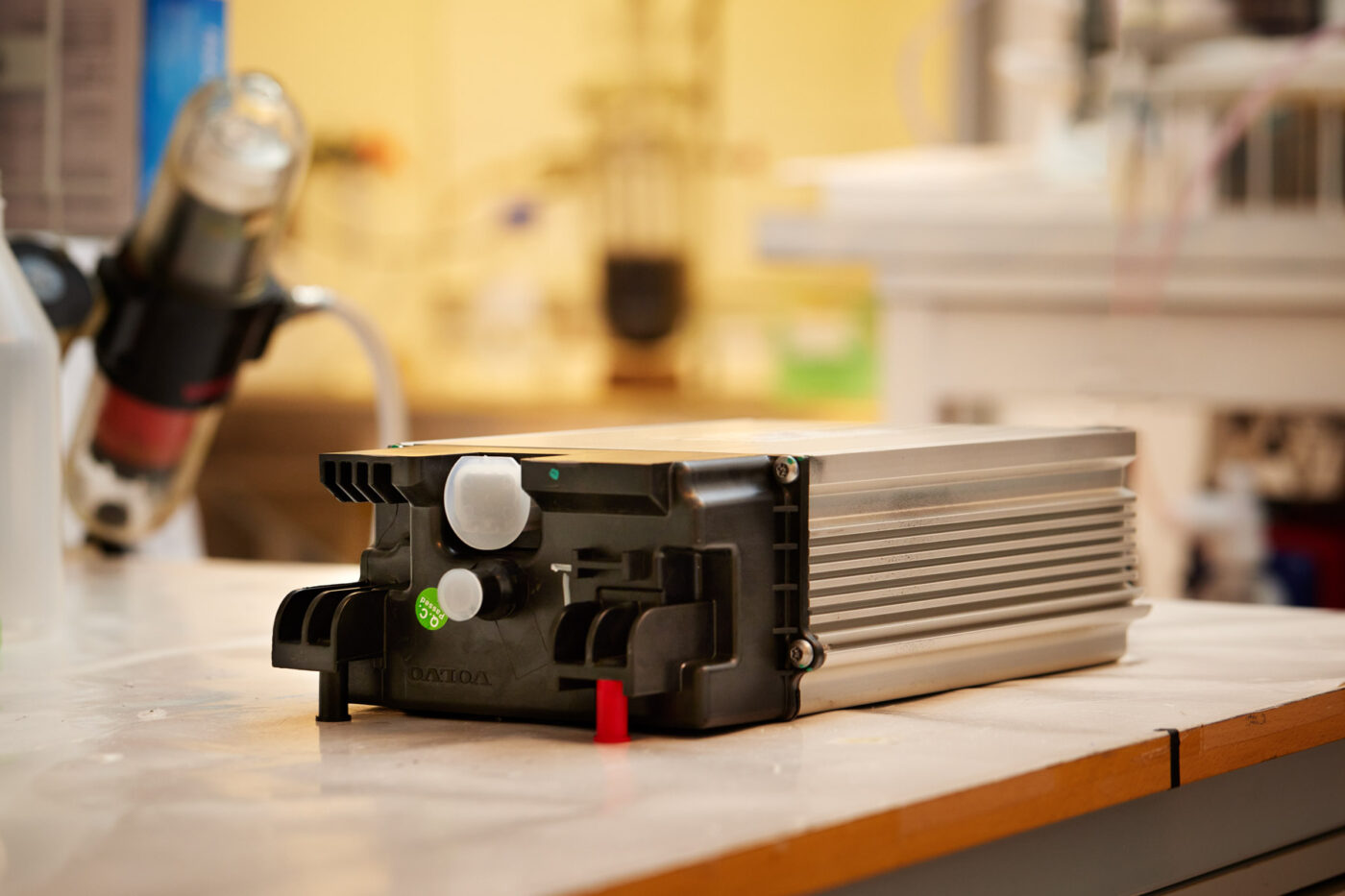

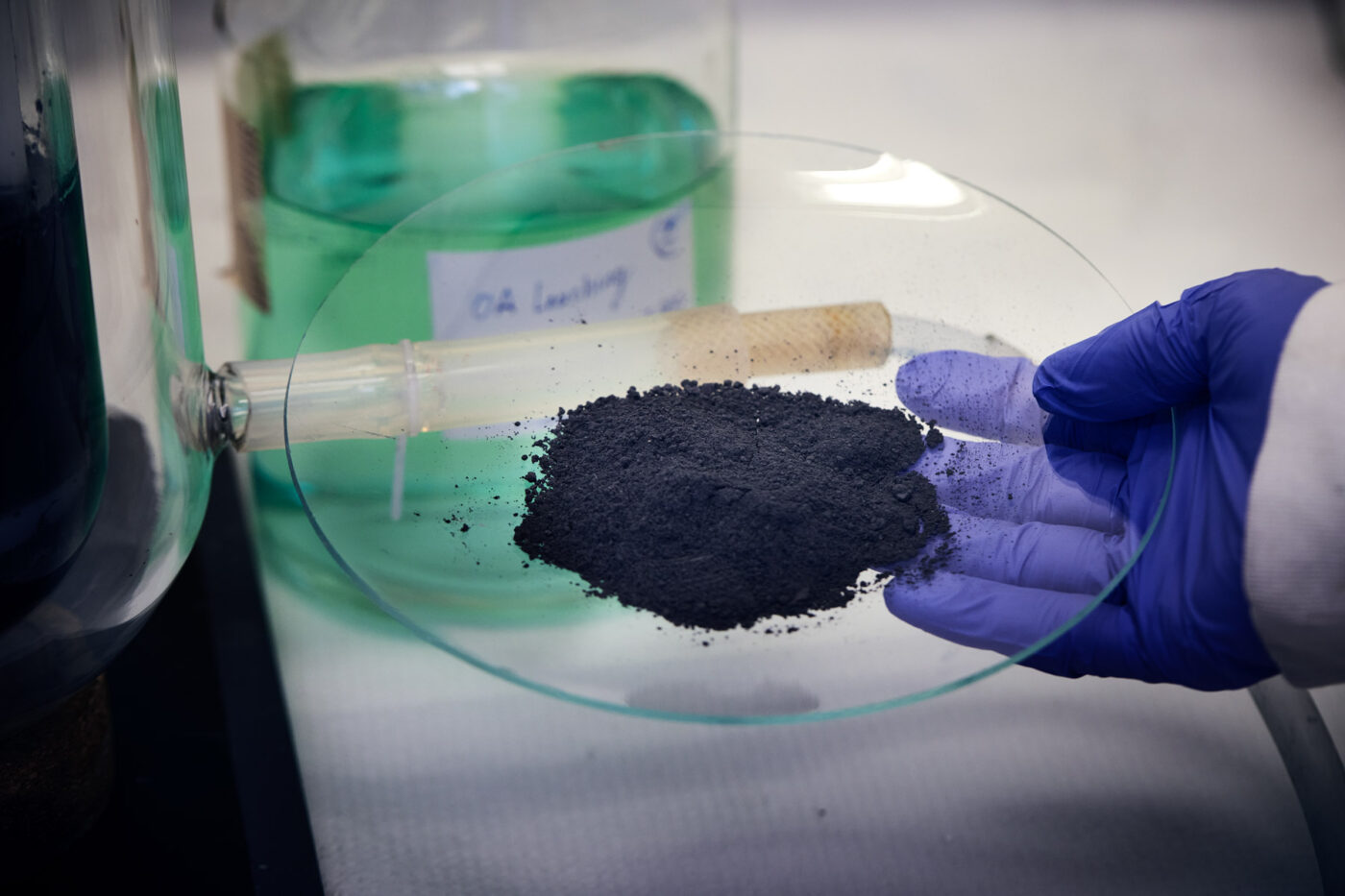

At Chalmers University’s battery recycling lab, the team experimented with processing black mass – the powdered mixture of a battery’s important active materials – in oxalic acid. Specifically, the battery in question is an e-car battery from Volvo. The memo describes the process as similar to “brewing coffee”. In fact, it is much more complex, as the temperature, concentration and duration had to be precisely matched in order for the procedure with oxalic acid to have the desired effect. Oxalic acid, by the way, is found in plants such as rhubarb and spinach.

“So far, no one has managed to find exactly the right conditions for separating this much lithium using oxalic acid, whilst also removing all the aluminium. Since all batteries contain aluminium, we need to be able to remove it without losing the other metals,” explains Léa Rouquette, a PhD student at the university’s chemistry department.

In the hydrometallurgical processes currently in use, the black mass is dissolved in an inorganic acid. Then, “impurities” such as aluminium and copper are removed to separately recover the active materials such as cobalt, nickel, manganese and lithium.

The researchers from Sweden note, however, that even with small residual amounts of aluminium and copper, several purification steps are required – and each step in this process could lead to lithium losses. With the new method, the researchers reverse the order and recover lithium and aluminium first. This allows them to reduce the loss of valuable metals needed to make new batteries.

There is also an analogy with brewing coffee in the next step: while aluminium and lithium end up in the liquid, the other metals remain in the “solids”. The next step in the process is the separation of aluminium and lithium. “Since the metals have very different properties, we don’t think it’ll be hard to separate them. Our method is a promising new route for battery recycling – a route that definitely warrants further exploration,” says Rouquette.

“We need alternatives to inorganic chemicals. One of the biggest bottlenecks in today’s processes is removing residual materials like aluminium. This is an innovative method that can offer the recycling industry new alternatives and help solve problems that hinder development,” says Martina Petranikova, professor in the department. However, the method needs further research, she adds. “As the method can be scaled up, we hope it can be used in industry in future years.”

0 Comments