German X-ray project should help improve batteries

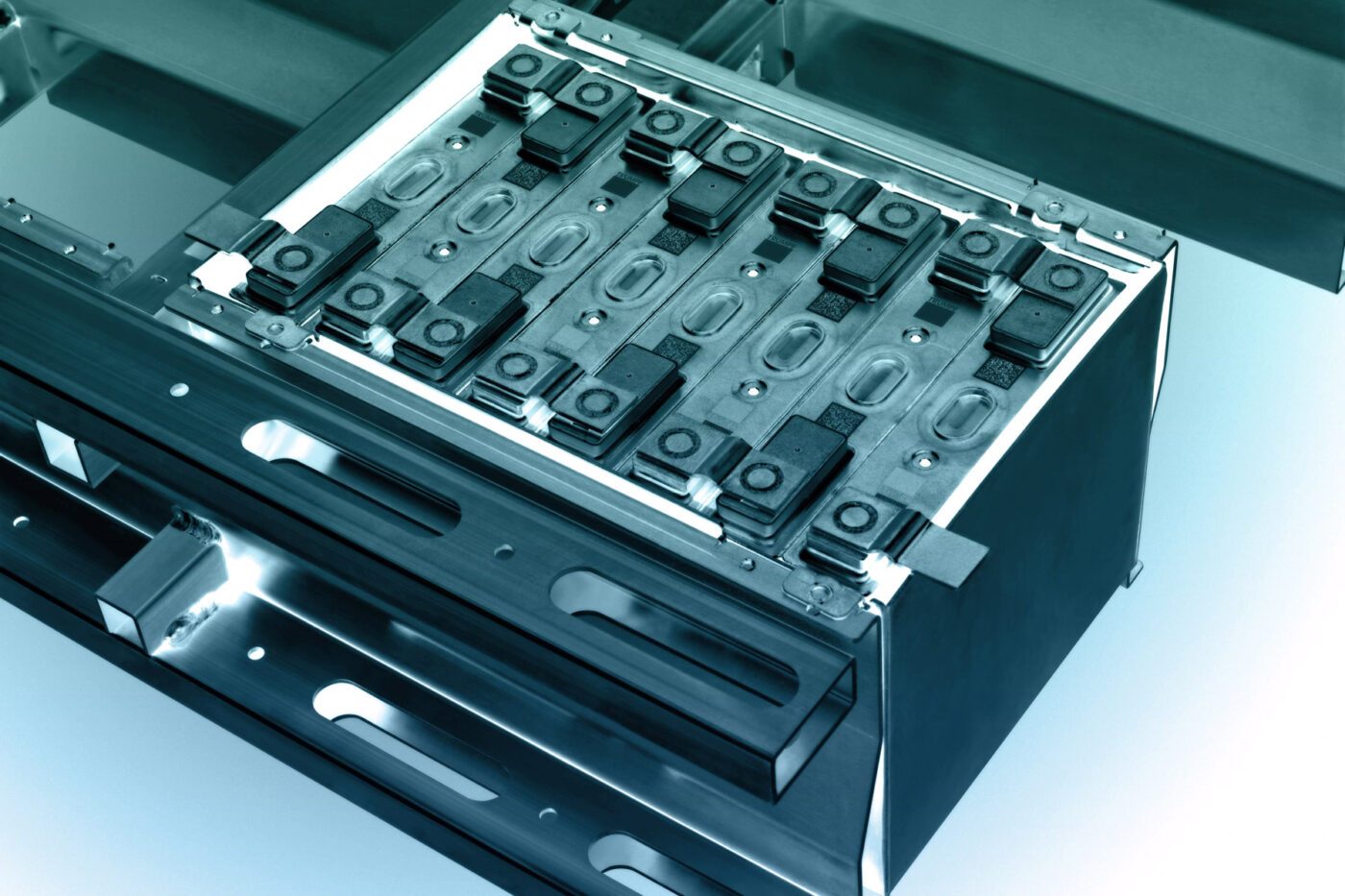

The XProLas development partnership has now started in Germany with the goal of producing the first demo systems by 2026. The systems currently being developed should enable manufacturers to monitor the charging and discharging of batteries in real time or determine impurities in the battery with particular precision. Manufacturers of electric car batteries could use the compact X-ray sources under development to X-ray batteries.

Under the lead initiative of Trumpf, Cellforce and BASF are also involved in the project, along with Amphos, Active Fiber Systems, Bruker, Excillum, Ushio Germany, Viscom, the University of Hanover and Fraunhofer Institutes in Aachen and Jena. The companies aim to incorporate the project’s findings into the development of new batteries. Trumpf says that the conclusions of the project’s analyses will, for example, enable manufacturers to improve the charging speed of electric car batteries.

The problem being solved by the multi-party project is that until now, the kinds of analyses under focus have only been able to be carried out on large particle accelerators that are over 100 metres long. The laser-driven X-ray sources under investigation in the XProLas project are only about the size of a mobile home and, therefore also considerably cheaper to manufacture, which Trumpf says will make them ideal for use in industry.

Another aim of the XProLas development project is to create a compact, high-brilliance X-ray source for analyzing cathode material. According to the project leader Trumpf, the exact composition of the cathode material can only be determined using X-rays. The project partners hope to replace large-scale research facilities with more compact, laser-driven variants in this field of application. This means that manufacturers of cathode material will be able to speed up their development work.

The multi-partner development project is being supported by the Federal Ministry of Education and Research (BMBF) with a research budget amounting to around 15 million euros.

0 Comments