BMW prepares plants for fuel cell production

While BMW is preparing a major shake-up with the debut of the new iX3 and, above all, the Neue Klasse at the IAA, the company is giving a glimpse of its next big e-mobility project a few days earlier: the long-awaited series launch of its first fuel cell vehicle.

The company’s competence centres in Munich and Steyr are currently building the first prototypes of the fuel cell system that will be installed in the production vehicle in three years. “Prototype production is currently focused on development and validation of the assembly and testing processes, with particular attention paid to industrialisation, quality assurance and scalability in the longer term,” BMW explains. The fuel cell systems from prototype production will then be used to develop operational strategies and validate the system at both vehicle and system level.

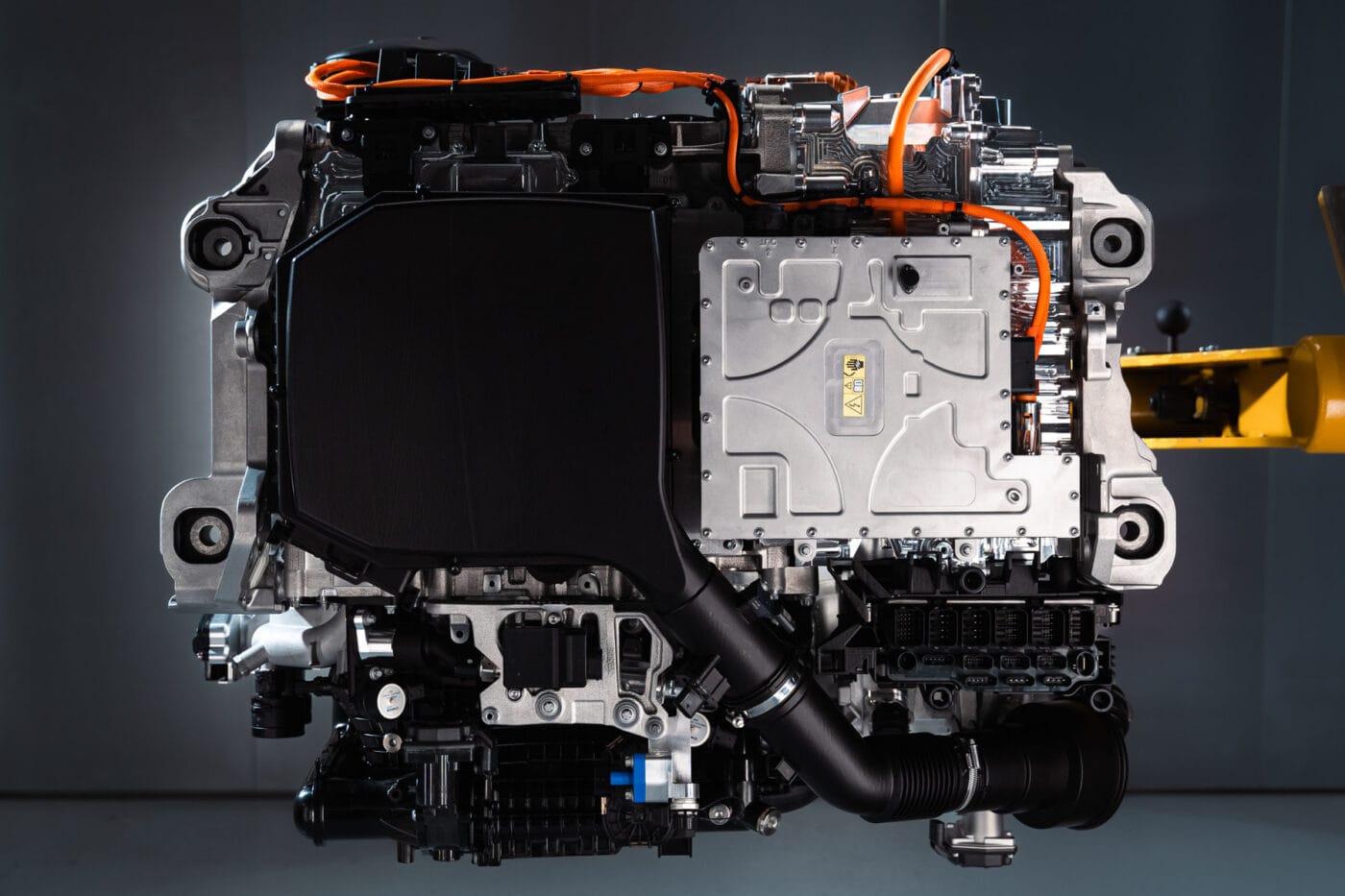

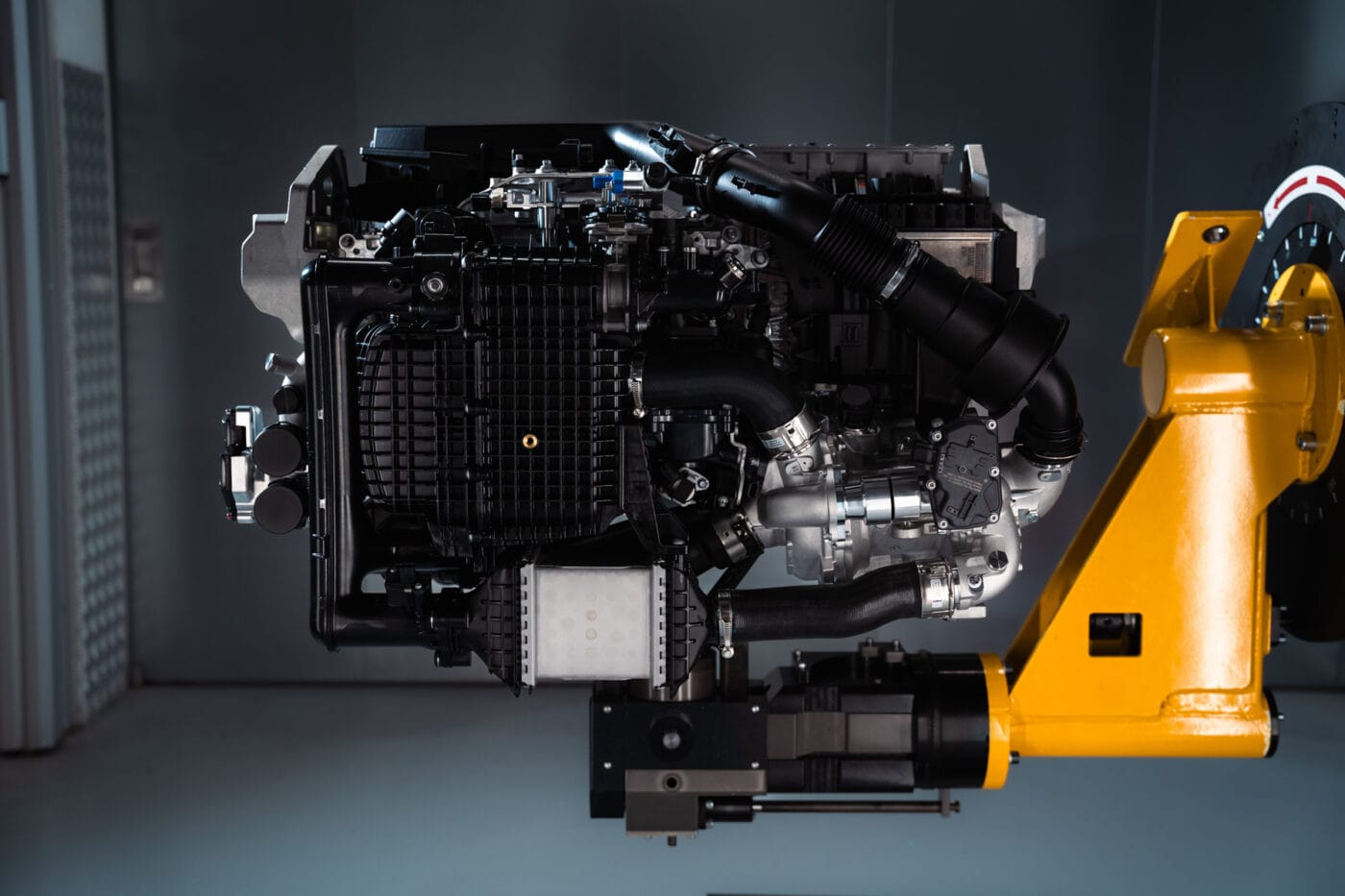

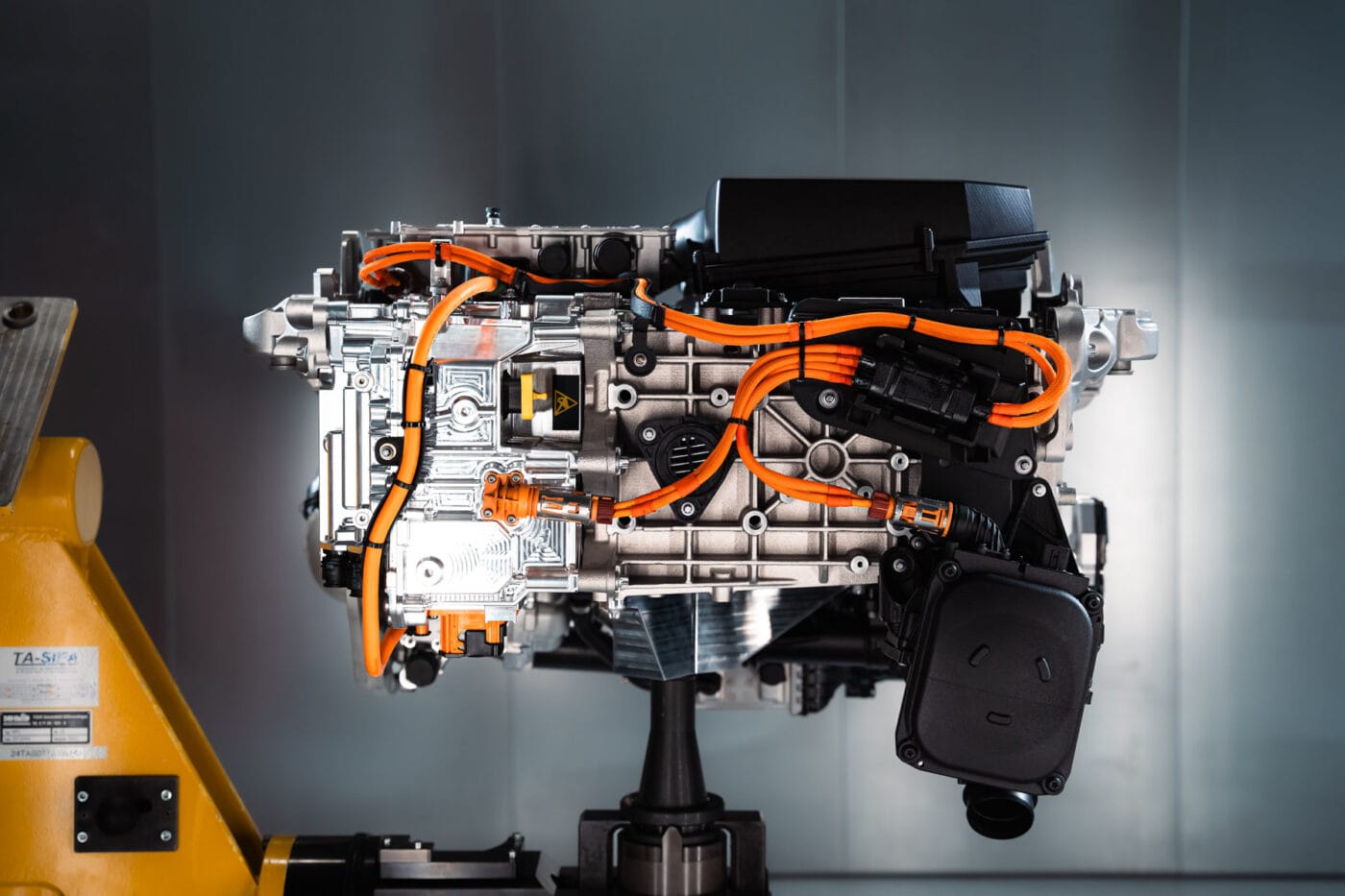

A bit of context: BMW works closely with Toyota on fuel cells. For the 2014 535iA, Toyota supplied the complete fuel cell drive – BMW integrated it into the vehicle, tested it, and gained experience. For the second generation, installed in the iX5 Hydrogen (here’s our test report), Toyota supplied only individual fuel cells. BMW developed the complete system itself. The fuel cell system includes not only the fuel cells but also all necessary components and subsystems required for efficient operation, such as the cooling system, hydrogen, and air subsystems.

New fuel cell system to be more compact and efficient

The third generation for 2028 is a joint effort between the two partners. “For the new generation, the BMW Group and the Toyota Motor Corporation jointly develop the powertrain system for passenger vehicles, with the core fuel cell technology creating synergies for both commercial and passenger vehicle applications,” BMW says. “This close collaboration enables both companies to leverage synergies in development and procurement while creating brand-specific models.”

Development focuses include efficiency, power density, and integration. Thanks to a significantly increased power density, the system is considerably more compact than the previous generation – the required installation space is 25% smaller. The high integration also makes the system easier to fit into various vehicle architectures, allowing BMW to maintain its technology-open approach, even though only one model has been announced so far.

Compared with the second-generation drive in the iX5 Hydrogen, efficiency is set to increase “substantially” – real-world range in our test matched current BEV levels. “This is being achieved by upgrading individual component parts that are based on the drive technology jointly developed with Toyota and by improved operating strategies,” BMW explains. “These improvements enable higher range and performance at lower energy consumption, representing a significant step up from the second generation.”

BMW has not yet disclosed specific data on the new drive system, such as stack performance and size, hydrogen tank capacity and technology, or vehicle range. However, the company has already outlined where and how the components for its own fuel cell drive will be produced.

The most important site is the component plant in Steyr, Austria, which already produces sixth-generation electric motors for Neue Klasse EVs – very likely also powering the 2028 hydrogen model. New test benches and production facilities are currently being installed and buildings adapted “to incorporate the new drive technology and constantly refine it.”

Landshut to supply key components

“We are proud to be producing another innovative drive technology at Plant Steyr in future alongside the latest generation of electric motors and combustion engines,” says Klaus von Moltke, Senior Vice President Engine Production at BMW AG and Director of BMW Group Plant Steyr. “This, together with the development expertise we have available on-site, makes our plant a prime example of the BMW Group’s technology-open approach.”

The Landshut plant will also play a role. From the end of May 2026, it will begin building new production lines for the series production of the hydrogen-specific “BMW Energy Master,” which manages energy supply in the vehicle – as in Neue Klasse battery EVs.

“This control unit is supplemented by various components that are specifically required for the fuel cell application,” BMW explains. “Production of the first prototypes of the hydrogen-specific Energy Master will begin in mid-2026 just a few miles away at BMW Group Plant Dingolfing, where the prototypes of the BMW Energy Master for the Neue Klasse models were also made.”

Additionally, the Landshut plant – as with the current iX5 Hydrogen pilot fleet – will produce the casing and media pressure plate for the next vehicle generation.

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments