Daimler Truck to build 100 advanced H2-powered semi-trailer tractors

After years of development and testing with first-generation prototypes, Daimler Truck has introduced the Mercedes-Benz NextGenH2 Truck as the next evolutionary step in its fuel-cell-powered heavy goods vehicle range. The refined model incorporates proven components such as the fuel cell from the joint venture Cellcentric and the liquid hydrogen technology already used in the first-generation truck. However, the NextGenH2 Truck now also benefits from series-production parts of its battery-electric counterpart, the Mercedes-Benz eActros 600, including the integrated e-axle, the aerodynamically optimised cab (‘ProCabin’), the Multimedia Cockpit Interactive 2, and several driver assistance systems.

As part of its recently announced small-series production plan, the manufacturer intends to build a total of 100 semi-trailer tractors in the coming months. However, full-scale series production is not expected before 2030. This delay follows Daimler Truck’s announcement of a cost-cutting programme in the summer of 2025, which includes deprioritising the GenH2 Truck. As a result, the planned start of series production was postponed from its original target of 2027 to the early 2030s.

Daimler Truck recently explained this decision, citing that ‘expansion of hydrogen refuelling infrastructure is progressing significantly slower than expected. As a result, customers will not be able to deploy hydrogen trucks in large numbers in the next few years.’ In addition to postponing the start of series production for the hydrogen truck, the group also anticipates lower production volumes. Furthermore, the German company is initially focusing its hydrogen powertrain development solely on Europe. That means the dual strategy—combining battery-electric and hydrogen-powered vehicles—remains in place for the European market, but not necessarily for other regions.

Daimler Truck first announced its intention to develop and build a fuel-cell truck in 2020. After several years of development, the first customer trials began in mid-2024 with Air Products, Amazon, Holcim, Ineos, and Wiedmann & Winz. Five vehicles were deployed, covering a total of around 225,000 kilometres, according to the company. In November 2025, the next phase of real-world customer testing followed as planned, involving five additional partners: Hornbach, Reber Logistik, Teva, Rhenus, and DHL Supply Chain. It is worth noting that these tests were conducted using the first prototype generation.

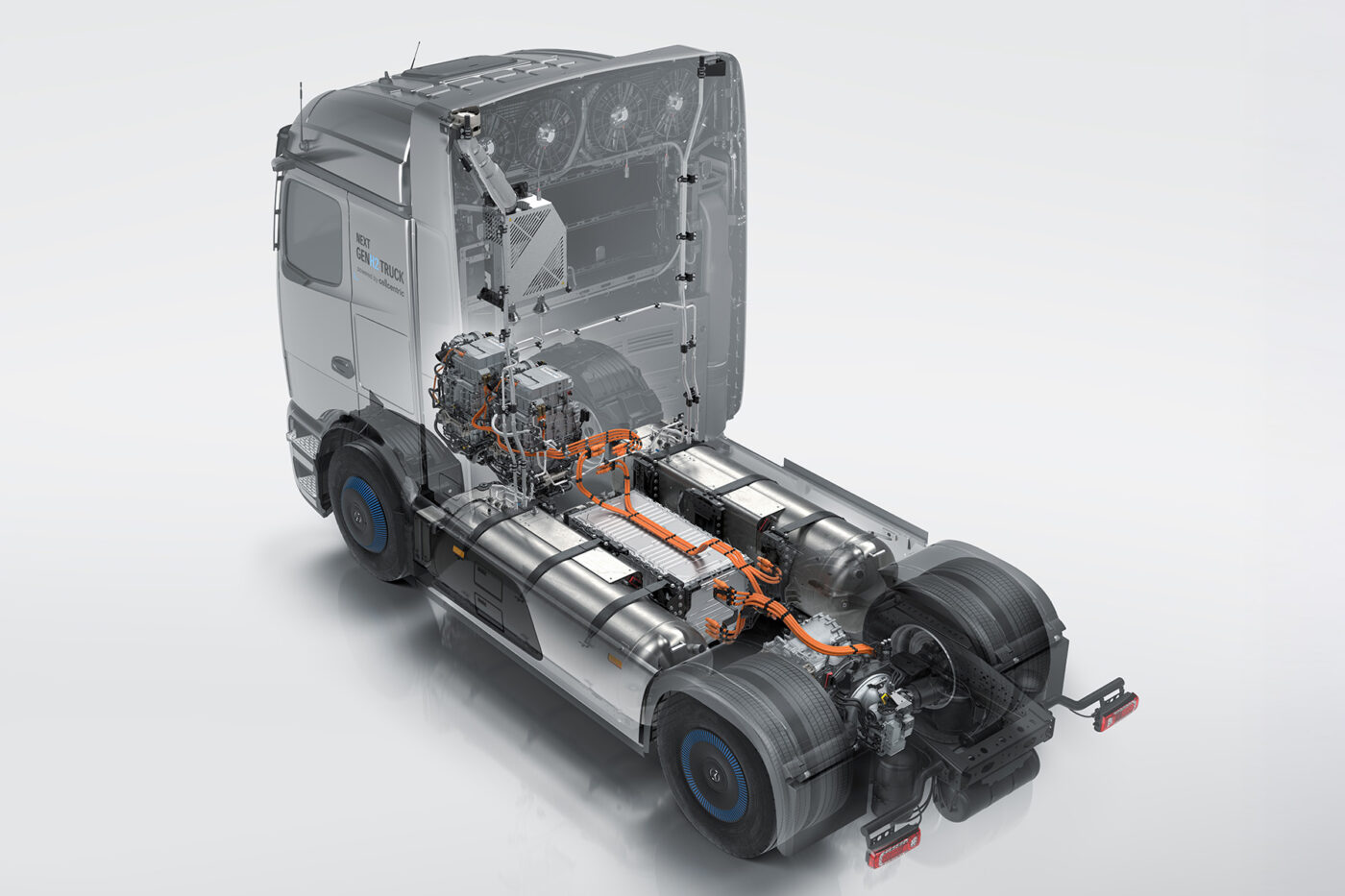

In parallel, the truck developers had already been working on the second generation, intended for small-series production. Daimler Truck has now unveiled this model with the following technical specifications: The centrepiece of the hydrogen truck remains the BZA150 fuel cell from Cellcentric (a joint venture between Daimler Truck and the Volvo Group), delivering a system output of 300 kW (2x 150 kW). This twin system is integrated into the engine compartment beneath the cab. Meanwhile, the capacity of the two liquid hydrogen tanks has increased to a combined 85 kilograms (previously 80 kg).

Daimler Truck continues to rely on liquid hydrogen (sLH2) as an energy carrier, as it offers a significantly higher energy density at -253 degrees Celsius compared to gaseous hydrogen, ‘allowing more hydrogen to be stored, substantially increasing range and delivering performance comparable to conventional diesel trucks.’ However, the drawback is that testing the NextGenH2 Trucks is far more dependent on infrastructure than battery-electric vehicles. Currently, these vehicles can only be refuelled at specialised sLH2 filling stations, which are available at only a few locations in Germany, such as Wörth am Rhein and the Duisburg area.

According to the manufacturer, refuelling the truck at such sLH2 stations takes between 10 and 15 minutes. Moreover, the use of liquid hydrogen ensures that the fuel-cell truck achieves a range of over 1,000 kilometres, as Daimler Truck demonstrated in September 2023: A road-approved prototype covered 1,047 kilometres on a single tank.

Returning to the technical specifications: The NextGenH2 Truck replaces the two previously used e-motors with the e-axle, including a 4-speed transmission, from the series-production eActros 600. It is an in-house development by the group. While the battery-electric version offers a continuous output of 400 kW and a peak output of 600 kW, Daimler Truck currently specifies up to 340 kW (in Economy Mode) and up to 370 kW (in Power Mode) for its hydrogen-powered counterpart.

To capture energy during downhill driving or braking and support the fuel-cell powertrain, the NextGenH2 Truck is equipped with a 101 kWh battery (the predecessor had a 70 kW battery). According to the German manufacturer, this is an LFP buffer battery developed specifically for this purpose. For comparison: The eActros features three LFP batteries, each with 207 kWh. The battery used in the fuel-cell truck thus corresponds to roughly “half” a battery module—just to illustrate the scale.

Additional components adopted from the battery-electric truck include all high-voltage components, the ProCabin (‘nine per cent improvement in the drag coefficient compared to the previous cab’), and the E/E architecture. Consequently, the NextGenH2 Truck incorporates the safety and assistance systems built on this architecture. Also new or revised are a Boil-Off Management System (to meet regulatory requirements for handling hydrogen), an integrated cooling system for stable operating conditions, new sensors (‘which responds to the highly unlikely event of hydrogen leakage, now allows overnight stays in the truck’s two standard beds fitted in the cab’), and a newly developed side skirt with integrated crash elements for enhanced protection of the liquid hydrogen tanks in accidents.

The manufacturer also states that it has succeeded in arranging the components in the ‘Tech Tower’ behind the cab more compactly, reducing its size and saving 15 centimetres in wheelbase. Compared to its predecessor, the NextGenH2 Truck now features a wheelbase of exactly four metres. “This increases customer flexibility by enabling compatibility with various trailer combinations and a wide range of standard trailers within EU length regulations,” Daimler Truck explains.

Daimler Truck has not provided details on payload capacity or fuel consumption. The predecessor offered a payload of approximately 25 tonnes with a gross vehicle weight of around 40 tonnes. During the first customer trials, consumption varied between 5.6 kg and 8 kg per 100 kilometres, depending on the application, with an average gross combination weight of between 16 and 34 tonnes. Significant differences in the advanced model are unlikely, however, as the manufacturer positions the NextGenH2 Truck as a semi-trailer tractor for ‘highly flexible and demanding long-haul applications,’ where everyday payloads and consumption levels are essential.

Achim Puchert, CEO of Mercedes-Benz Trucks, comments: “n addition to battery-electric solutions, hydrogen-based drives are crucial for the sustainable transformation of our industry. With the NextGenH2 Truck, we are taking the next technological step in fuel cell trucks. Together with our customers, we aim to introduce the small series with high range and near production-ready technology into daily transport operations from the end of 2026.”

The development, production, and practical deployment of the NextGenH2 Trucks are supported by the German Federal Ministry of Transport and the German federal states of Rhineland-Palatinate and Baden-Württemberg with funding totalling 226 million euros.

0 Comments