CALB sets its sights on European production

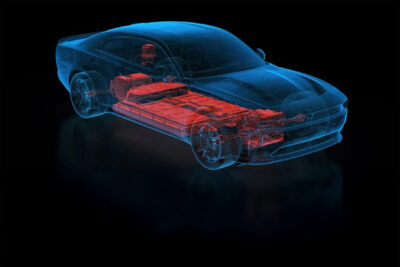

With CALB, short for China Aviation Lithium Battery Technology, another battery manufacturer from China aims for Europe. The state-owned company claims to produce lithium-ion batteries with NCM as well as LFP chemistry – in the order of 100 GWh per year.

In Europe, the company plans to build its own battery factory, according to the latest information. CALB emerged from a state-owned subcontractor in 2007, has its headquarters in Luoyang and about 1,700 employees worldwide. The company produces cells and modules for electric cars, commercial vehicles, stationary story systems for renewable and mini-grid, and grid-balancing projects.

The cars in which CALB’s battery technology is installed include the GAC Aion S and the GAC Aion V, several vehicles from Changan, the Geely Emerand EV450, the Geely Geometry C as well as the DFM Fengon E3 and the IA5 from GAC-Toyota. CALB cites three bus manufacturers (Kinglong, Foton, Yutong) and a van from UPS as references.

In a press release sent to us at electrive by email, CALB wrote that the company is aiming to double its production capacity to 200 GWh “in the near future”. Currently, the state-owned company has an R&D centre and three production sites in Changzhou, Luoyang and Xiamen.

Parallel to the increasing capacity in China, CALB wants to expand worldwide. The construction of a European factory is already planned. The company says it has founded a subsidiary to boost this project and organise pre-sales and after-sales services in Europe. As yet, CALB has not revealed further details on the time frame or location for the European factory.

In addition to the above-mentioned customers in the automotive market, the battery manufacturer has announced further partnerships by email. For example, it is a designated supplier to Honda and Guangqi Honda and plans “bulk deliveries” to GAC-Toyota and a French bus project. Projects are also in planning in Japan and India.

On a very recent front, CMB International, a wholly-owned subsidiary of China Merchants Bank, published an equity research company update on the GAC Group 3Q20 noting that: “The profitability of GAC NEV has gradually improved given 1) economies of scale brought by sales growth and 2) battery cost control given the introduction of new battery supplier CALB.”

From our own reports at electrive, the Chinese battery maker has indeed been making steady inroads into European markets. Back in 2017, we reported that the German supplier ElringKlinger set up a joint venture with Chengfei Integration Technology (CITC). The agreement will see CITC contribute lithium-ion battery cells via its subsidiary China Aviation Lithium Battery (CALB). At the same time, ElringKlinger will add all other module components and also oversee design and production.

We also reported a new cooperation in a joint venture between Continental and CALB in 2019. Continental’s joint venture with CALB will manufacture complete 48-volt systems with a motor, control unit, and battery in Changzhou. While CALB supplies the battery cells, Continental contributes to the battery management system, including the underlying software. The company’s goal is to start production of technically advanced battery systems by 2021. “The Chinese market will continue to be of pivotal importance for the future development of electric mobility,” confirmed Andreas Wolf, head of Continental Powertrain.

In April 2020, CALB also featured in a study conducted by a team at the Environment Campus Birkenfeld in Trier – not using metadata, but real-world tests and measurements. The researchers collected as much data as possible themselves – by dismantling a VW Caddy with a 1.6-litre petrol engine, analysing it and rebuilding it with an electric drive.

To electrify the Caddy, the Trier researchers opted for Lithium Iron Phosphate (LFP) cells from the Chinese manufacturer CALB. They installed a battery with an energy content of 25.9 kWh. They also simulated a battery twice the size with 51.8 kWh and included the original materials of the battery cells (according to the manufacturer CALB) in the analysis. In contrast to the nickel-cobalt-manganese (NCM) technology frequently used in the automotive industry, the LFP cells do not contain cobalt with its related extraction problems, especially in the Congo.

Source: via email, en.calb-tech.com, gg-lb.com (in Chinese)

0 Comments