California looks at fuel cell trucking requirements

The Californian Fuel Cell Partnership (CaFCP), a coalition of government and multinational industry partners, have released a new foundational document for heavy-duty class 8 fuel cell electric trucks. The policy recommendation envisages 70,000 trucks supported by 200 heavy-duty truck stations by 2035.

The document called “Fuel Cell Electric Trucks: A Vision for Freight Movement in California and Beyond” aims to guide government policy and industrial activity along the West Coast. The document outlines economic and strategic viability noting that “As a complementary and viable alternative to battery-electric trucks, fuel cell electric trucks are the optimal one-to-one replacement solution for diesel trucks.”

“California has set aggressive goals to achieve zero-emission fleets across vehicle categories, including cars, buses, and trucks,” said Bill Elrick, executive director of CaFCP. “We can only achieve these goals through collaboration between government and private industry, and policies that promote and attract investment. The time to act—and invest—is now, if we intend to transition quickly and successfully to a self-sustaining market.”

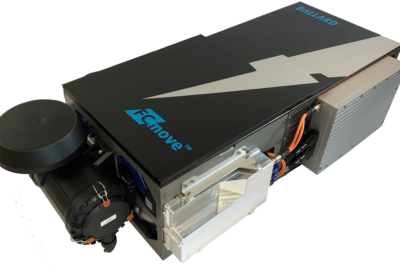

The Californian Fuel Cell Partnership is a coalition that includes government organisations such as the California Air Resources Board (CARB) and the US Department of Energy Efficiency and Renewable Energy, as well as multinational corporations such as Ford, Hyundai, Shell Hydrogen, Cummins, Toyota, Ballard, Daimler, Chevron, Air Liquid and General Motors among many others.

The policy recommendation document comes on the back of the Advanced Clean Trucks rule implemented by the Californian government around this time last year that requires manufacturers to sell a gradually increasing proportion of electric trucks, vans and pickup trucks from 2024 onwards until 2035. By the year 2045, every new commercial vehicle sold in the US state should have zero-emission propulsion.

The CaFCPsays that, with the right policy mechanisms in place, California can achieve a self-sustaining fuel cell trucking market by 2035. Last month the Port of Los Angeles deployed five new hydrogen fuel cell vehicles and opened two hydrogen fueling stations with partners that include Toyota, Kenworth Trucks and Shell. The Port of Los Angeles is the nation’s busiest port complex and is served by a fleet of more than 18,000 drayage trucks.

The document on fuel cell trucks was also contributed to by the Californian Governor’s Office of Business and Economic Development. Contributions from members, staff, and key non-member stakeholders who participated in workshops, discussions, and reviews organised by the coalition led to the development of the document.

1 Comment