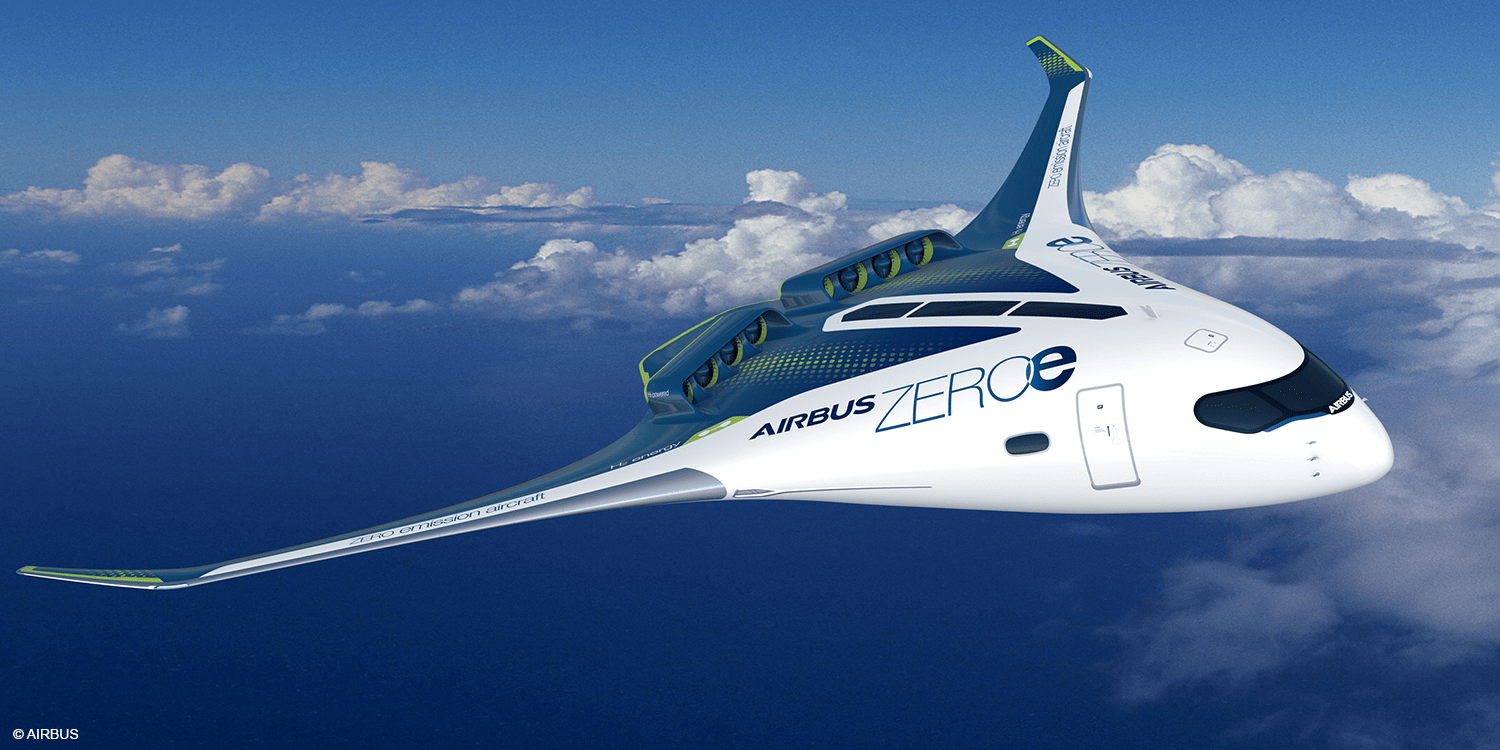

Hydrogen fuel cell aircraft – what for and when?

With increasing fuel prices and climate change, the aviation industry is having to look at life after fossil fuels but is facing a particularly tough challenge – passenger aircraft needs to be light and very safe, and what about longer distances? We asked aviation insiders where hydrogen fits in.

* * *

We caught up with Andy Reynolds, Head of ZEROe, the hydrogen program at Airbus, and experts from ZeroAvia at the Reuters Hydrogen conference in Amsterdam, as well as start-ups working on new solutions presenting at Germany’s largest aviation trade show, the ILA, in Berlin.

Although experts agree that hydrogen is key to all low-emission solutions beyond small, local flights, all of these options are only optimal for some sections of the industry, and all of them face big challenges before they become commercially viable – so it’s complicated.

In short, there is no single solution to aviation without fossil fuels. To understand where hydrogen fuel cell technology fits in, it is prudent to give a very quick and broad overview of non-fossil fuel options:

Battery electric aircraft are already in use. Due to the required energy density to get aircraft off the ground, these are only considered feasible for smaller, local aircraft.

Synthetic and biofuels – called Sustainable Aviation Fuel (SAF) – will theoretically be able to power regional aircraft, but here, more development is required to have aircraft running on 100% SAF, as well as to remove the remaining CO2 and toxic emissions. Hydrogen plays a role here: While bio SAF is made from left-over oils, such as cooking fat, hydrogen feedstock can be used for synthetic SAF, which is already being blended into kerosine fuel and used by, for example, KLM in the Netherlands. Even so, these fuel types are generally not considered feasible in the kind of abundance required to cover current demand.

The only zero-emission solution for larger regional passenger aircraft is currently hydrogen fuel cell electric propulsion systems. These use hydrogen in gaseous form, but much higher energy density can be achieved with liquid hydrogen, which requires cryogenic tanks to store the hydrogen at extremely low temperatures, sometimes at -253 degrees Celsius. We will come back to this later.

While SAF and hydrogen fuel cells are both viable for regional flights, some planes still need to travel further. So far, the only viable non-fossil fuel option for intercontinental flights is hydrogen combustion engines – which is what NASA has been using for years to send rockets into space. This is not entirely emission-free and comes with its own challenges.

Hydrogen is key to all low-emission solutions

Following the series of panel discussions on the future of aviation at the ILA, their press office surmised at the end of the show: “All participants in the panel on hydrogen at the ILA Future Lab agreed: hydrogen has what it takes to make aviation climate-neutral. But there was also agreement that the associated challenges are great and require joint efforts worldwide.”

Andy Reynolds of Airbus confirmed this statement when speaking to us at the Reuters hydrogen conference in Amsterdam. The head of the Airbus ZEROe unit is not just involved in hydrogen fuel cell aircraft but has been working on fuel efficiency in aviation for 30 years. While Reynolds sees the immediate option for decarbonising aviation in SAFs, he says: “We believe it (SAF) is potentially still not enough.” Especially when looking at the kind of abundance required to cover current demand.

David Morgan, head of Flight Operations at EasyJet agrees: “Yeah, availability of SAF is an issue.” EasyJet is already blending small percentages of SAFs in flights today, as are other airlines such as KLM.

Hydrogen can be produced in a number of ways but is only emission-free if made via electrolysis from renewable energy, so-called green hydrogen. “The availability of ability of cheap energy to produce the hydrogen potentially to produce the SAF or just to be used directly is going be the key. So, it’s places in the world where we can get relatively cheap energy and then produce (hydrogen). That’s going to be key to where it’s going start,” explains Reynolds.

Airbus has started to get ready. In June this year, industrial gases company Linde signed a memorandum of understanding with Airbus to work on the development of hydrogen infrastructure at airports worldwide.

In April this year, the fuel cell aviation start-up ZeroAvia announced a new partnership with ZEV Station to develop green hydrogen refuelling infrastructure at airports.

Like in other industries, because of the higher costs of transporting hydrogen, the most affordable and doable option for hydrogen infrastructure is for it to be produced on-site or as close as possible. In September last year, Airbus and Air New Zealand announced a joint initiative to research the ways in which hydrogen-powered aircraft could assist the airline with reaching its goal of net-zero emissions by 2050.

When can we expect zero-emission regional aircraft?

Larger regional zero-emission aircraft are not expected to be in commercial operation until the mid-2030s. Here, Airbus and ZeroAvia have clear goals. Says Reynolds: “Airbus has started very, very seriously. What we’re working on is a hundred people, a thousand nautical miles probably in the mid-thirties. It’s a huge challenge to get there, but we believe it’s achievable.”

For ZeroAvia, getting there is a different process. ZeroAvia is not an aircraft manufacturer and is still an early-stage company that is about four and a half years old. Zero Avia CFO Katy Akulincheva says: “We are a propulsion company. We’re not building a new aircraft. We’re building a new powertrain system that uses green hydrogen as an input initially in gaseous form, but over time using liquid as well, and then uses fuel cells to convert that back to electricity. We chose that system early on because it’s the best way to true zero and take into account some of the non-CO2 effects as well.” Here she is referring to the toxic gases produced by both SAFs and hydrogen combustion, which engineers and scientists still have to work on eliminating.

She explains, “We see our role to really scale that particular solution up starting with small aircraft, where technology is already, where it needs to be, to deploy that very in the very near term. Our first product will be introduced in 2024, and that can power aircraft up to 20 seats.” Beyond these goals, she says: “Over time, we think that technology can scale to aircraft of a larger size to the regional space and hopefully beyond.”

Just last month, ZeroAvia began cooperating with Otto Aviation to develop a fuel cell propulsion system for a long-range Otto aircraft. The ZA600 hydrogen-electric powertrain from ZeroAvia will be adapted for the Celera aircraft from Otto Aviation.

While Airbus is one of the world’s largest aircraft manufacturers next to Boeing, there is a lot of admiration and interest for start-ups with a solely zero-emission focus. “It’s going be really interesting to see how people like ZeroAvia introduce much smaller products. They will be ploughing the furrow for us a little bit in terms of certification,” says Andy Reynolds.

Retrofitting existing aircraft and moving on to liquid hydrogen

The aviation industry currently has around 26,000 commercial aircraft in operation. The enormous task to decarbonize the sector will not only rely on completely new aircraft or using new fuels in old aircraft but also on retrofitting old aircraft with new powertrains.

This is the aim of a private-public partnership that has just begun in the Netherlands called HAPPS, standing for Hydrogen Aircraft Powertrain and Storage System. This major partnership is building a hydrogen system that can be used to retrofit existing regional aircraft. The partners hope this system will allow commercial hydrogen-powered aircraft to take off with their help in 2028 and aim for the planes to have a capacity of 40-80 seats. The company is already aiming for a 10-20 seat commercial plane on hydrogen by 2024.

The HAPPS system envisages replacing a classic combustion turboprop engine with electric motors that get their power from fuel cell systems positioned in the engine bays behind the motor and propellors. Liquid hydrogen tanks will be placed in the tail of the aircraft. However, like Airbus, ZeroAvia and others, HAPPS will have the challenge of cryogenic liquid hydrogen storage tanks to reach a higher energy density. This has been a major focus at Airbus.

In May, Airbus opened a Zero Emission Development Centre (ZEDC) for hydrogen technologies in the UK. A priority for the UK ZEDC in Filton near Bristol will be the development of a low-cost cryogenic tank. According to Reynolds, “One thing that Airbus is very clear on, we are not the experts in cryogenic hydrogen, and that it is difficult.” However, he adds, “It’s really interesting as an engineer to begin with it. So, recruiting people to join the project is not a problem. Getting them aligned and delivering is more difficult and understanding the scale of all the things that we have to do.”

In Germany, there was a recent breakthrough on this front: The German fuel cell aircraft developer H2FLY says it has started final preparations for the integration of liquid hydrogen tanks into the HY4 test aircraft. An intensive programme of ground tests is scheduled to start in early 2023.

Is enough being done fast enough?

What quickly became clear is that hydrogen, whether for SAF, fuel cell technology or combustion is the future of aviation beyond fossil fuels – but when will it grow to scale? Here Reynolds pointed out that a lot of people from all over the hydrogen industry talk about driving down the cost of green hydrogen. “We’re always talking here about green hydrogen and that it’s critical today.” He explains, “You know, both ends of that equation are probably going to shift. The price of kerosene is probably going to go up, and hopefully, we can drive the price of hydrogen down. And the reason that Airbus is investing a lot of people and resources and money in zero-emission technology is so that we have an option for the airlines on the day that hydrogen is obviously the fuel of choice.”

When that day comes is not certain. When asked what might happen if the price of oil – and therefore jet fuel – goes up faster than expected, Reynolds answers: “We’re pushing really, really hard on suppliers on ourselves on the supply side. Is it fast enough? Well, time will tell.”

Report by Carrie Hampel, editing by Nora Manthey

3 Comments