MAN announces battery recycling strategy

MAN Truck & Bus is working on an after-use strategy for its batteries. The manufacturer is currently drawing up an action protocol for this. In parallel, MAN has launched a project to test used MAN vehicle batteries in stationary storage facilities.

MAN Truck & Bus wants to start early to ensure the subsequent use of its batteries. Customers of new vehicles are already to be trained to drive and charge the vehicles in a battery-friendly manner. Should parts of the battery pack nevertheless suffer a defect, the following protocol applies: “If parts of the battery pack suffer a defect during use, e.g. individual modules no longer function, repair of the battery is planned as a first measure. The battery can then be used again in the vehicle. The batteries that come back to MAN after use in the vehicle are analysed intensively. In the event that the battery packs can no longer be used as so-called traction batteries, they are forwarded to secondary applications.”

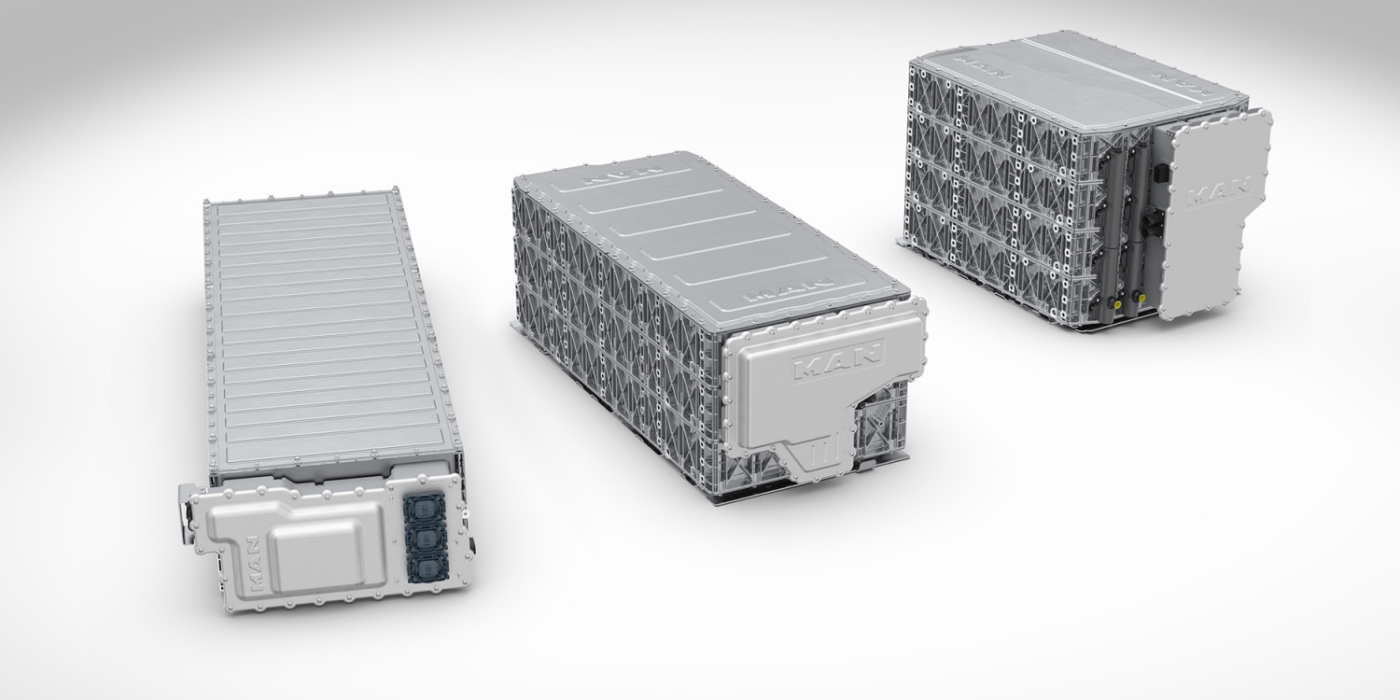

According to the company, there are three options for this as things stand today: A second use in the vehicle after factory repair (“2nd Use”), a second battery life (“2nd Life”), for example as buffer storage for solar or wind power plants, and the recovery of the battery raw materials for new batteries in the sense of closed-loop use (“Recycling”).

MAN is currently working with various partners and the University of Kassel on projects to evaluate whether used truck batteries are suitable for stationary storage. To this end, the company is handing over around 120 truck battery packs with an energy content of 18.6 kWh per pack to a storage manufacturer. The batteries come from the first field trial with battery-electric distribution trucks from MAN, which began in 2018 in Austria and lasted three years. The project partner at the time was the Council for Sustainable Logistics.

When it comes to recycling, MAN strives for a closed cycle for the battery raw materials. The raw materials recovered by recycling partners, such as nickel, manganese, cobalt or lithium, should therefore flow into the new production of batteries. For recycling, MAN says it prefers a mechanical process followed by hydrometallurgical treatment. “At present, the recycling rate is more than 70% in relation to the weight of the battery,” MAN states. As part of the Volkswagen Group recycling network, MAN cooperates with partners throughout Europe.

MAN is still in the process of developing its after-use approach. According to the manufacturer, there is still some time left: “The number of batteries that have come to the end of their service life in vehicles will therefore only reach industrial levels in around 10 to 15 years,” the company headquarters wrote.

0 Comments