BASF & partners to localise battery supply chain in North America

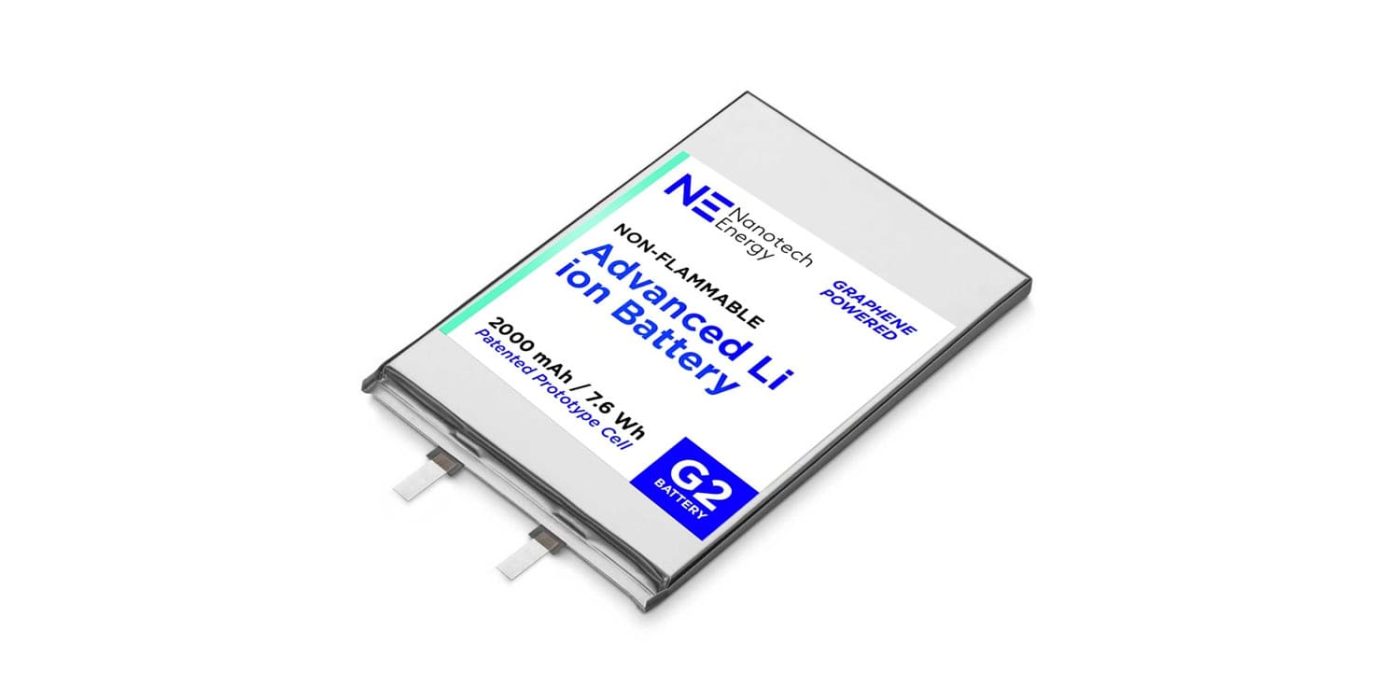

BASF and Nanotech Energy have struck a deal to close the loop for lithium-ion batteries in North America. BASF will produce cathode active materials from recycled metals in Michigan for lithium-ion battery cells produced by Nanotech Energy.

BASF says it will be the first company in North America to provide cathode active materials produced with recycled metals on a commercial scale starting in 2024 but with support from American Battery Technology Company.

ABTC is a battery recycling company in Reno, Nevada, as reported. Also part of the newly forming network is TODA Advanced Materials, which specialises in manufacturing pCAM (precursor for Cathode Active Material) and metal hydroxide material. Toda is headquartered in Ontario, Canada, and the last link in BASF’s “localised battery value chain for the North American consumer electronics and automotive industries”.

Along that chain, battery scrap and off-spec material from Nanotech’s pilot plant in Chico, California, and its planned commercial facility will be recycled by ABTC. The partners explain that the metals recovered by ABTC – such as nickel, cobalt, manganese, and lithium – will subsequently be used by TODA and BASF to produce new precursors and cathode active materials. Nanotech will then reuse these materials in its battery cell production, closing the loop.

Daniel Schönfelder, Senior VP of Battery Base Metals and Recycling at BASF, called the partnership with Nanotech, ABTC, and TODA an “important step for BASF’s global battery recycling business”.

The company has already been providing recycling services and cathode active material based on recycled metals as a closed-loop solution in Asia for years, also in cooperation with Toda, as reported.

BASF has also announced similar steps in Europe, where it inaugurated its cathode materials factory in Brandenburg, Germany, in June 2023. The plant in Schwarzheide is already sold out for the next few years. It is expected to manufacture battery materials for over 400,000 electric vehicles annually, reportedly using precursors from BASF’s plant in Harjavalta, Finland.

As with the US operations now underway, BASF said it was the first company to establish a “co-located battery materials and recycling centre and close the loop in the European battery value chain – from the collection of used batteries and the recovery of mineral raw materials to their use in the production of new battery materials”. The battery recycling plant is currently under construction. It shall come online by 2024.

BASF also appears to plan a battery recycling plant in Tarragona, Spain. Official confirmation is outstanding, but the facility is on the list of 41 clean-tech projects the EU is funding with more than 3.6 billion euros.

0 Comments