Battery manufacturing seal to be ready by 2022

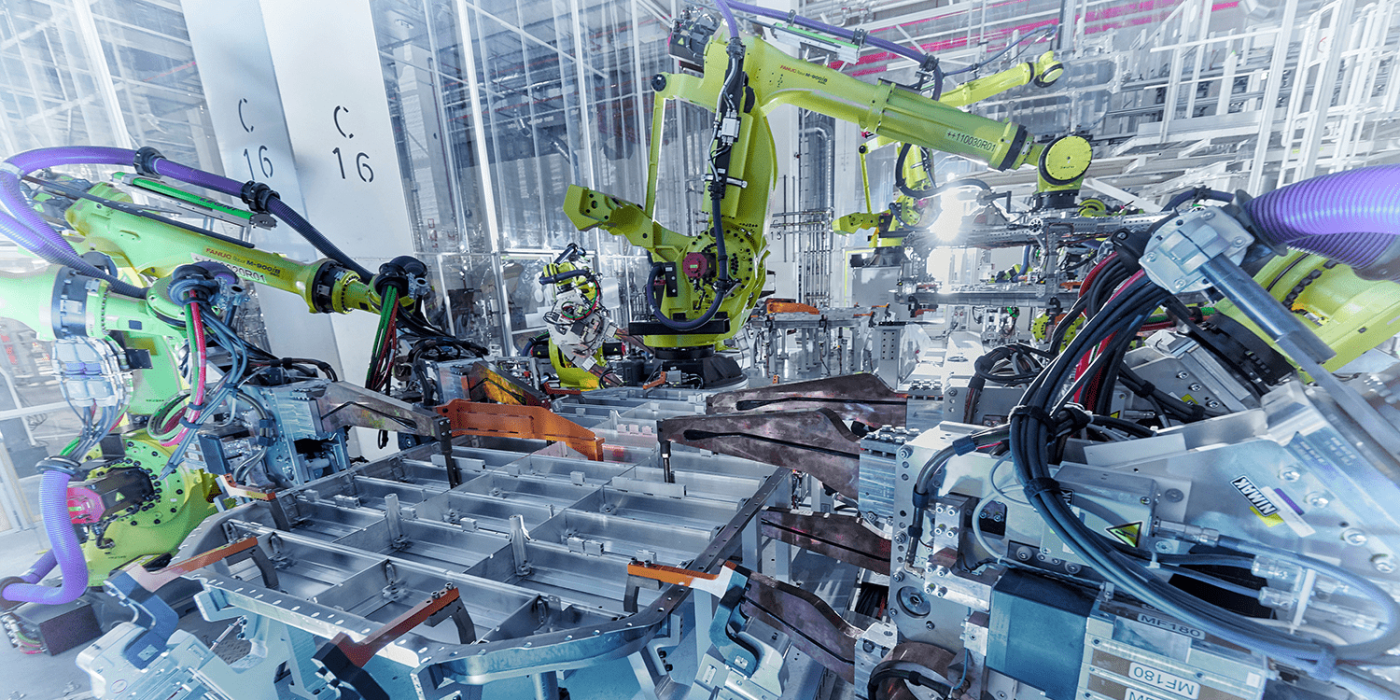

The Global Battery Alliance wants to complete its planned seal for fairly manufactured batteries by 2022. A prototype should be ready by the end of this year. The aim is to provide consumers with significantly more information about the production of the batteries when they buy an electric car, among other things.

One of the other issues the alliance seeks to tackle is to certify that no child labour is used in the extraction of cobalt and that safety and health standards are observed. With the battery passport, the companies involved in the Global Battery Alliance (GBA) want to counter the recurrent criticism of the production of batteries for electric cars by publishing important factors in the seal in a uniform manner.

A prototype is to be produced by the end of 2020 and the first version in 2021, as GBA member BASF told the German Press Agency (DPA). According to this, “full functionality” is not to be achieved until the end of 2022. BASF CEO Martin Brudermüller hopes that the battery pass will make “social, ecological and economic criteria transparent”. “The value-adding chain of batteries offers great opportunities to contribute to sustainable development,” Brudermüller said.

However, the GBA did not announce the scope (and thus the significance for the end customer) of the prototype and the first version. According to Audi, the aim is to “create a comprehensive and internationally recognised sustainability seal for batteries”. This should also include concrete limit values “in the individual stages of the value chain” – for example for water consumption or CO2 emissions. However, it remains to be seen which values will then be classified as “good” or “bad” in the seal. According to BASF, representatives of consumer groups, civil society organizations and governments would also be involved in the JCC’s discussions.

Uncertainties surrounding the 2022 target

Within the JCC, however, there are obviously different views on the timetable. As Volkswagen informed the DPA, the project is still in the conception phase. The VW subsidiary Audi is becoming a little more specific: “It can be assumed that no less than three years will be necessary to adequately process the – technologically – extensive value-added branches,” the Ingolstadt-based carmaker said in a statement.

BASF’s CEO Brudermüller heads the GBA together with Benedikt Sobotka, head of the Luxembourg-based raw materials group Eurasian Resources Group. Eurasian can then set a good example straight away: According to the group, it is considering building a plant to manufacture NCM battery materials for electric vehicles. After a two-year construction period, the first phase is expected to produce 90,000 tonnes of NCM per year. A later expansion is to be determined depending on market conditions.

With reporting by Sebastian Schaal, Germany.

heise.de, automobilwoche.de (both in German), eurasianresources.lu

0 Comments