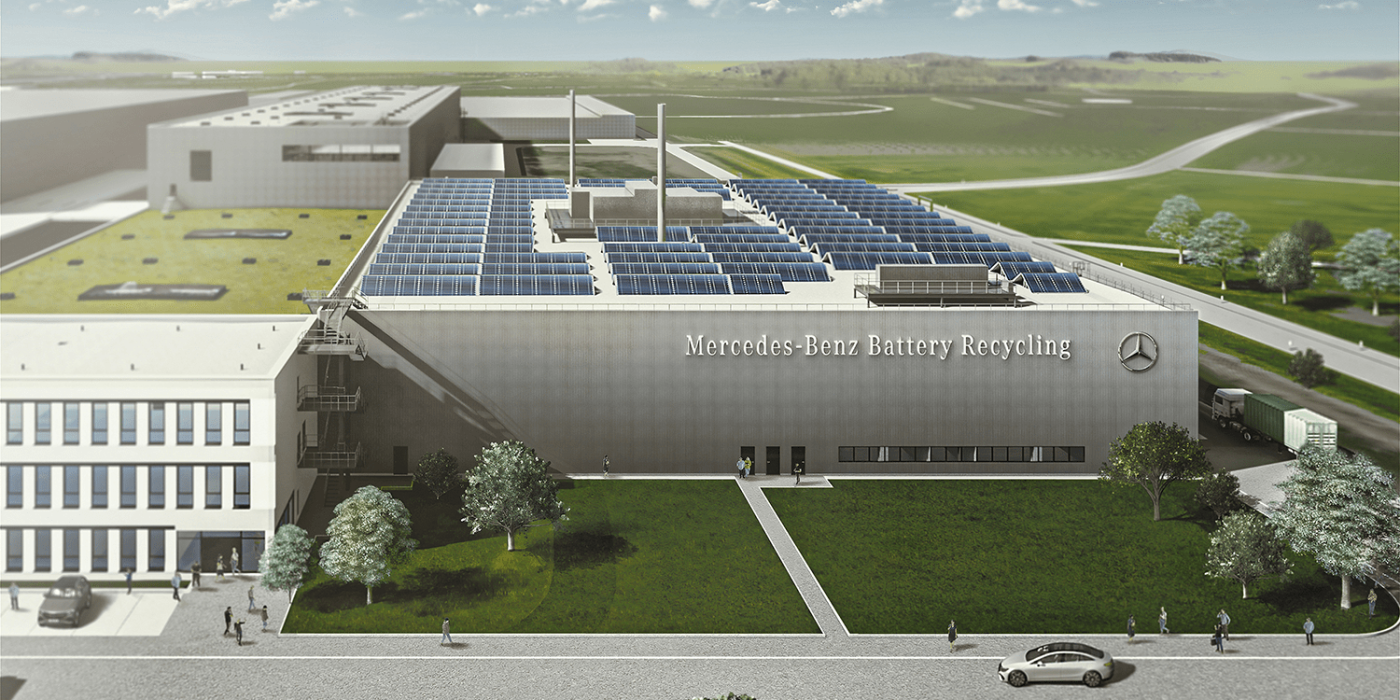

Mercedes lays foundation stone at battery recycling plant

Mercedes-Benz has laid the symbolic foundation stone for the announced battery recycling factory in Kuppenheim. For the first stage of the plant – mechanical dismantling – commissioning is to start at the end of this year. Talks with the public sector about further expansion are still ongoing.

According to the Mercedes release, these talks are “promising” thus far. The plan is to supplement the mechanical dismantling with hydrometallurgy a few months later. This would allow Mercedes to map the entire chain in its pilot plant, from the discarded battery packs to the extraction of the individual raw materials in Kuppenheim.

“This innovative approach for an integrated recycling concept within a single factory is currently unique in Europe,” the carmaker writes. Although Volkswagen Group Components has had its pilot recycling plant in Salzgitter in operation for just over two years, not all steps are carried out there. VWGC only carries out the mechanical processing, at the end of which the so-called black mass with the valuable battery materials is produced. In the case of the VW plant, the hydrometallurgical processing itself is separated into individual components by “specialised partners” – Mercedes wants to be able to do this in-house in Kuppenheim in future.

In total, the Stuttgart-based carmaker is investing an unspecified amount in the double-digit millions in the construction of the “balance sheet CO2-neutral plant”, as it says in the press release. However, the recycling factory is also being funded by the Federal Ministry of Economics and Climate Protection as part of a scientific research project. In this project, called ‘LiBinfinity’, Mercedes, together with partners such as Primobius, the SMS Group and research institutes, wants to develop a hydrometallurgical process that should achieve a recovery rate of 96 per cent. This will make “a true circular economy of battery materials possible”, according to Mercedes.

Later plant expansion is possible, but not confirmed

The first reports about a pilot recycling plant in Kuppenheim came out two years ago. Later still, the then Daimler group confirmed such plans for the Gaggenau plant, to which Kuppenheim belongs. Later, the Kuppenheim site was confirmed and an annual capacity of 2,500 tonnes was also mentioned. “Based on the findings of the pilot factory, production volumes could be scaled up in the medium to long term,” Mercedes writes carefully outlining plans for the future.

However, since there will not be enough batteries in recyclable condition from retired e-cars in the foreseeable future, Mercedes wants to recycle mainly batteries from test vehicles and “start-up batteries” in Kuppenheim – i.e. rejects from production and its own test facilities that do not meet the quality standards for series-production vehicles but still contain valuable materials. “If necessary”, batteries from “field returns” will also be processed in Kuppenheim, i.e. batteries that have to be removed from the vehicles prematurely. However, Mercedes does not expect high quantities here.

“This foundation symbolises the decisive step towards closing the material cycle for batteries from Mercedes-Benz,” says Jörg Burzer, the board member responsible for production and supply chain management. “With a recycling rate of more than 96 per cent, a ‘mine of tomorrow’ is being created here in Kuppenheim. The innovative technology approach enables us to incorporate the valuable raw materials into new Mercedes-EQ vehicles.”

Baden-Württemberg’s Environment Minister Thekla Walter, who had also come to Kuppenheim for the laying of the foundation stone, emphasised the political dimension of such recycling projects. “Crises such as the corona pandemic or the brutal Russian war of aggression against Ukraine have clearly demonstrated our dependence on supply chains and primary raw materials,” said the state minister from the Green Party. “Increased recycling can help to reduce this dependence on critical raw materials and thus strengthen the resilience of the economy. In this respect, the topic of battery recycling is highly topical and also of strategic interest.”

0 Comments