Toyota integrates recycled battery material from Redwood

Toyota and Redwood Materials already work together. The supply of battery components made from recycled material is the core of an extended cooperation agreement now concluded by the two companies, which builds on a collaboration announced in 2022 for collecting and recycling used batteries from Toyota hybrid cars. The goal is to establish a circular, domestic supply chain to produce batteries for Toyota’s electric and hybrid cars.

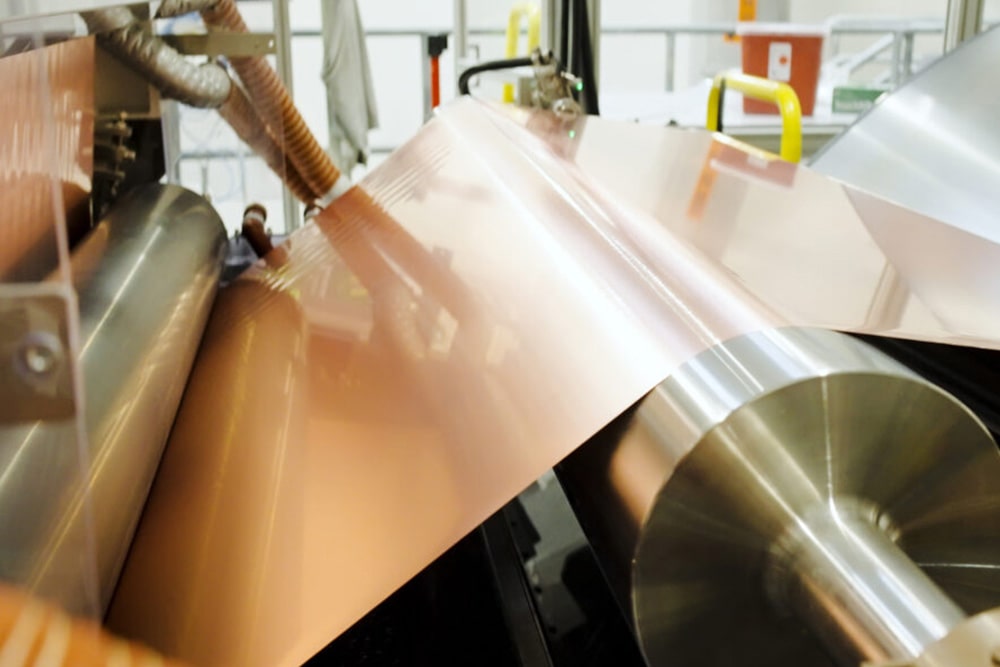

According to Redwood, the company hopes to recycle at least 20 per cent of the cathode material for Toyota from nickel and lithium and 50 per cent from cobalt. The foil for the anodes will consist of 100 per cent recycled copper. Absolute delivery quantities or delivery periods are not specified. However, both sides are talking about a “long-term agreement.”

“Today, in collaboration with Redwood Materials, Toyota is making a decisive move toward a sustainable future,” says Cal Lankton, Redwood Materials’ Chief Commercial Officer. “They’re not only working to ensure responsible end-of-life management for their electric vehicles but also planning to build their next generation of EVs, in part, by using sustainable and domestically manufactured battery components.”

Christopher Yang, Group Vice President, Business Development at Toyota Motor North America, adds: “Accelerating our recycling efforts and domestic component procurement gets us closer to our ultimate goal of creating a closed-loop battery ecosystem that will become increasingly important as we add more vehicles with batteries to roads across North America.”

Toyota recently announced a massive increase in investment in its North Carolina battery plant by 8 billion to 13.9 billion US dollars. The factory is scheduled to go into operation in 2025.

The money will be used to create eight additional production lines for BEV and PHEV batteries. According to Toyota, there will still be only four production lines for batteries for hybrid vehicles. By 2030, Toyota aims to achieve a battery production volume of more than 30 GWh per year in North Carolina.

“With today’s announcement, Toyota North Carolina solidifies its position as the company’s epicentre of lithium-ion battery production in North America. Overall, the campus will boast seven million square feet, equating to 121 football fields of battery production,” the automaker wrote in a press release earlier this month.

Toyota Motor North America recently announced that it has secured cathode materials from LG Chem for the plant in North Carolina. Deliveries are expected to start in 2025. In addition to the batteries it produces itself, Toyota will also purchase batteries from LGES. From 2025, LGES will supply battery modules with a total capacity of 20 gigawatt hours per year, which contain NCMA pouch cells with a high nickel content and will be installed by Toyota in new electric cars manufactured in the USA. Toyota will also produce its first BEV model in the USA from 2025: An SUV with three rows of seats that will roll off the production line in Kentucky.

0 Comments