Hyvia to deliver fuel cell architecture for the Renault Master

This new architecture adds the two smaller variants L2H2 (10.4 cubic meters) and L3H2 (12.6 cubic meters) to the current Renault Master H2-Tech L3H3 series with 14.4 cubic meters of load space. The “current Renault Master series” refers to the familiar model. Renault also presented the next generation of the Master at Solutrans, which will also have two BEV versions – more on this model in a moment.

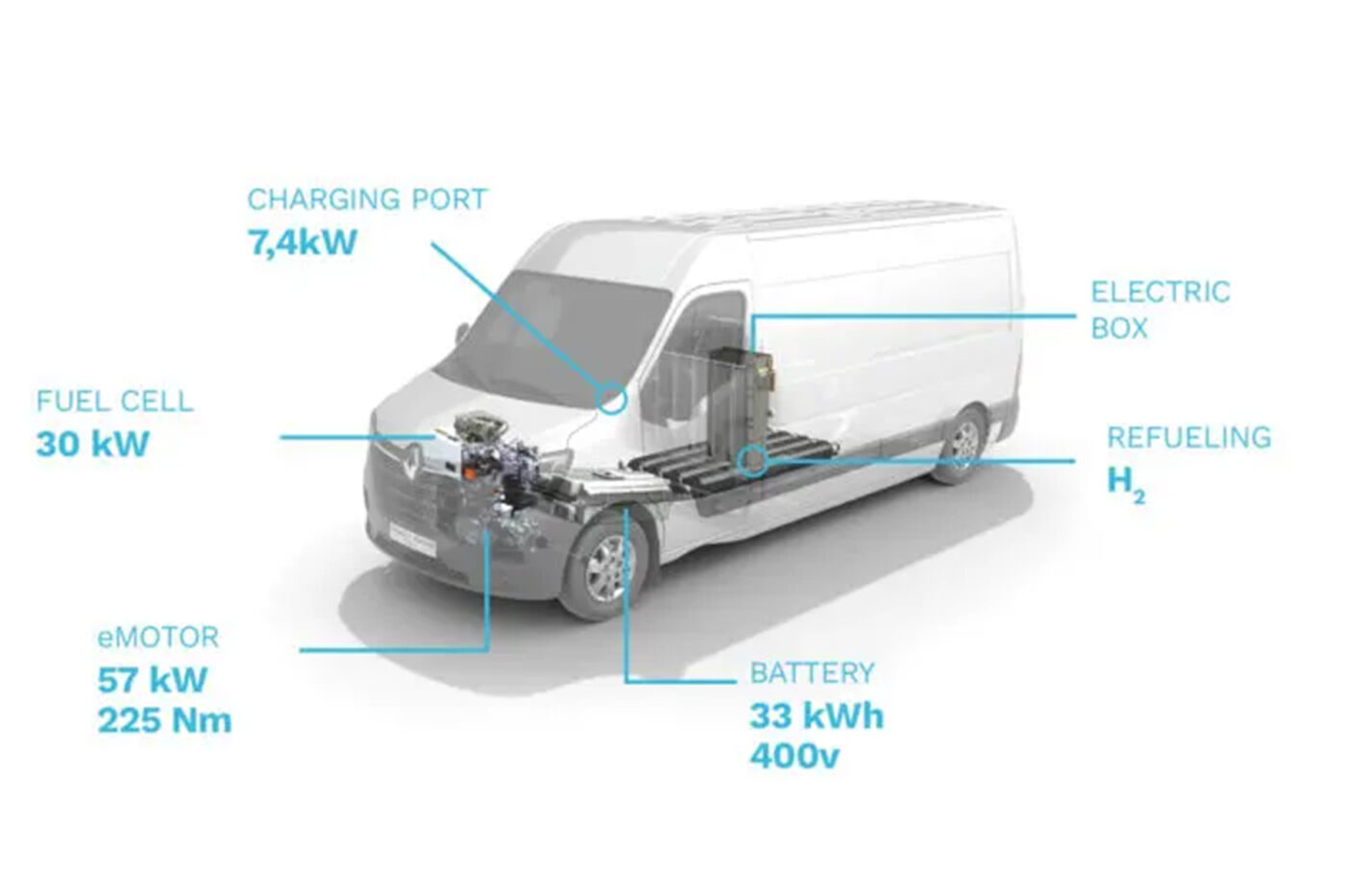

The biggest change concerns the position of the hydrogen tanks: in the panel van that Hyvia presented in October 2021, the four H2 tanks with a total capacity of six kilograms were located on the vehicle roof. In future, the hydrogen tanks will be located in the underbody. The electric drive continues to deliver 57 kW, while the fuel cell, which is also installed in the engine compartment, delivers 30 kW. It works together with the 33 kWh battery, which is located under the driver’s cab, to supply the engine with power. The 400-volt battery can also be charged externally (via a charging port on the passenger side) with 7.4 kW. The filler neck for the hydrogen is installed on the driver’s side. There is an additional electric storage unit in the load compartment, which takes up 0.4 cubic meters of the load compartment.

For the current generation, the payload increases to up to 1,389 kilograms with the new FC architecture, according to Hyvia. The company promises refuelling times of less than five minutes and WLTC ranges of up to 320 kilometres. The new architecture of the Renault Master H2-Tech should also enable further conversions – for example as a workshop vehicle, ambulance or refrigerated vehicle. As the installation space for the H2 tanks on the roof is no longer required, there are new possibilities for the bodywork. An L3H3+ with Sortimo bodywork was also on display at Solutrans.

In addition, Hyvia is developing a new generation of hydrogen-powered vans based on the new Master presented by Renault at Solutrans, which are to be launched on the market in several versions from 2025 – although no technical data has yet been provided. The new generation will then be manufactured completely in the regular production process at the Batilly plant with the other drive types – subsequent conversions should no longer be necessary. According to Hyvia, this will make it possible to increase the number of units produced. The fuel cell system will be built by Hyvia in Flins.

0 Comments