Stellantis to invest €30 billion in e-mobility

Stellantis has presented its new electrification strategy. The multi-brand group wants to achieve 70 per cent of its sales in Europe and 40 per cent in the USA with “low emission vehicles” by 2030. In Europe, Opel is to become an electric brand by 2028.

By 2025, Stellantis wants to invest more than 30 billion euros in electrification and software, as CEO Carlos Tavares announced at the ‘Stellantis EV Day’. The company wants to “continue to be a pioneer in the efficiency of automobiles”, said Tavares, and achieve an investment efficiency that is 30 per cent better than the industry average.

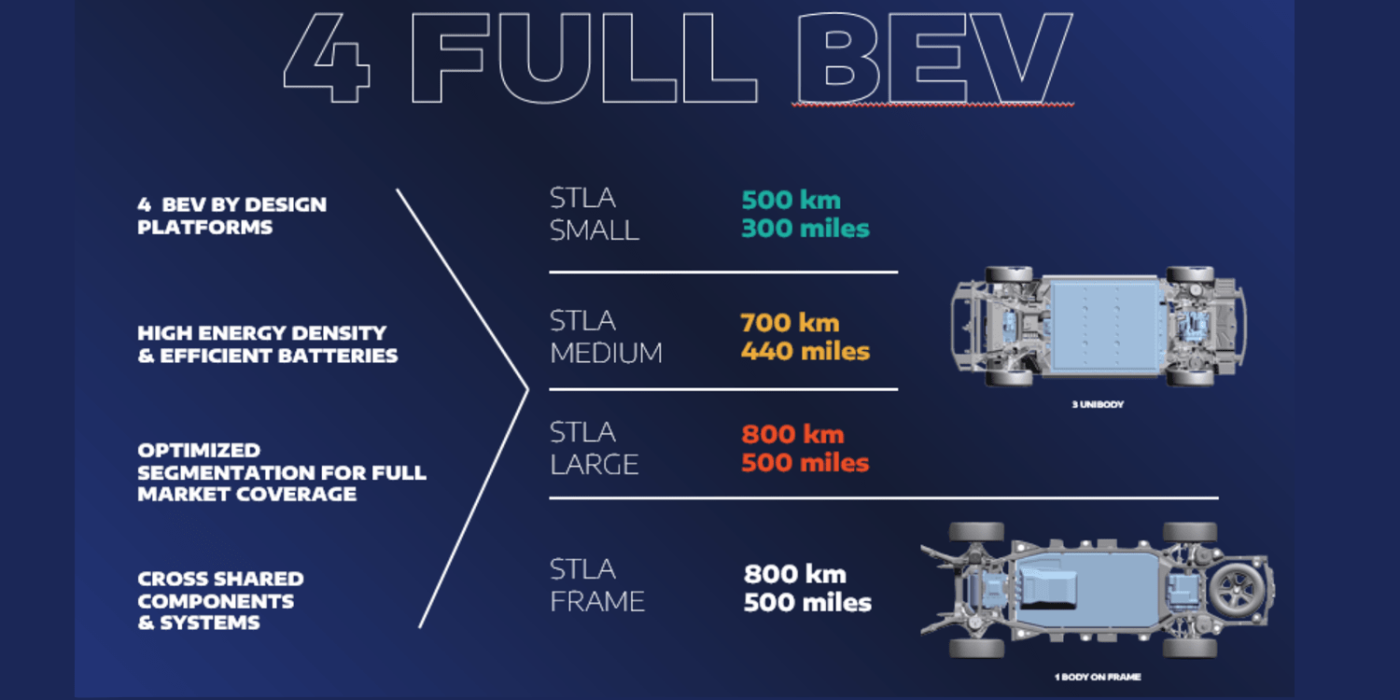

This money is to be used to drive forward the electrification of the 14 Group brands – 98 per cent of models in Europe and North America are to be electrified. This is to be achieved with four purely electric platforms. According to Tavares, even the platform for the smallest vehicles should be able to achieve ranges of 500 kilometres, with up to 800 kilometres possible for larger vehicles. “This will allow us to serve customers’ range requirements in most segments – without them having to change the way they use their vehicle,” Tavares said.

The Stellantis CEO estimates that 260 GWh of batteries will be needed in 2030. This is to be covered by five gigafactories and supply contracts. After the ACC battery factories in France and Kaiserslautern, which Tavares initiated when he was still head of PSA, he was now able to confirm factory number 3 at EV Day: “We have concluded an agreement with the Italian government to develop our engine plant in Termoli into a battery factory,” he said, without revealing further details.

Tavares did mention one more important key figure: starting from 2026, he wants to achieve double-digit operating margins with the business model for electric cars.

Of course, the group’s electrification also has consequences for the brands and their vehicle ranges. As Opel boss Michael Lohscheller announced in a video clip, Opel is to become a pure electric brand in Europe by 2028. As early as 2024, every Opel model is to be electrified. By “the middle of the decade”, the Manta-e is to be launched on the market, which was announced after the reactions to the Manta GSe ElektroMOD. Opel also wants to enter the Chinese market – exclusively with electric models.

Fiat will also become an EV brand sometime between 2025 and 2030. “As soon as we can offer e-cars at the cost of a combustion engine, we will become purely electric,” said Fiat brand CEO Olivier Francois. For Abarth, this step should take place as early as 2024 – as a sporty offshoot, Abarth is not as dependent on affordable prices as Fiat.

Four platforms, three powertrains, two cell chemistries

In the US, performance brand Dodge plans to launch its first electric muscle car in 2024, Ram will sell an electric version the 1500 in 2024. Jeep wants to offer plug-in hybrids in all SUV segments by 2024, the Wrangler 4xe is already sold out for this year. The Jeep Wagoneer is to be targeted as an all-electric premium SUV primarily for the US market.

To cover the range between affordable small cars, family cars, sports cars and large pickups, the four platforms are meant to be STLA Small, STLA Medium, STLA Large and STLA Frame. “The platforms are designed around the battery pack. This is how we achieve the best efficiency,” says Patrice Lucas, the manager in charge. “Each platform is designed for specific vehicle lengths and widths.” To reduce costs, key components are shared across all platforms. Each of the platforms will be scaled up to two million units per year to realise the cost benefits.

In more detail, Lucas cites the Large platform that is intended for vehicles between 4.70 and 5.40 metres in length; they can be between 1.90 and 2.03 metres wide, so a business sedan, a Dodge muscle car or even a family SUV would be feasible. Eight models based on this platform are already in development and are expected to be launched in three to five years.

Solid-state battery to debut in 2026

The STLA Small is made for battery sizes between 37 and 82 kWh – the latter should be enough for the 500 kilometres mentioned. The range is somewhat smaller for the other platforms: STLA Medium is designed for 87 to 104 kWh, STLA Large for 101 to 118 kWh. The batteries are significantly larger in the STLA Frame, the ladder-frame platform for the large pickups. Since the range should remain sufficient even with heavy loads, batteries between 159 kWh and 200 kWh are planned here.

For the batteries, Stellantis relies on two cell chemistries across the Group: The cheaper version is to do without nickel and cobalt, but will probably not be an LFP chemistry. In addition to lithium, Stellantis specifies iron and manganese as materials. These will have an energy density of 400 to 500 Wh/l at cell level and will be integrated into the vehicles using the cell-to-pack approach, meaning they will not require modules.

The second cell chemistry is nickel-based, with a nickel-manganese cathode. At cell level, the target is 600 to 700 Wh/l, but modules are still to be used here initially. The step to cell-to-pack has been announced for 2026. Stellantis is also aiming for the first use of a solid-state battery in vehicles in 2026. However, the company did not give any details on this at the EV Day – it only stated that it would rely on existing production facilities for the manufacture of these batteries.

Battery contracts for the USA about to be signed

Stellantis hopes to gain decisive cost advantages from the batteries. The cobalt-free version is to be 20 per cent cheaper than the nickel-based cell. Overall, the batteries are expected to be 40 per cent cheaper at module and pack level by 2024 than they were in 2020.

For 2025, Stellantis assumes a global demand of 130 GWh for the group, 80 GWh of which will be in Europe. In addition to the gigafactories of ACC (the joint venture together with Total subsidiary Saft), the cells are to be sourced from CATL, BYD, SVOLT, Samsung and LG Energy Solution, preferably from their European plants. The 50 GWh for the USA are to be procured from partners, while names are not yet mentioned since final negotiations are reportedly still underway.

In 2030, the demand will be the 260 GWh mentioned above, of which more than 170 GWh will be in Europe. Half of this – 85 GWh – is to be covered by ACC. Either ACC will have to expand the factories in Douvrai, Kaiserslautern and Termoli or build further gigafactories.

Lithium from geothermal brine

Incidentally, Stellantis has not identified nickel or cobalt (which will soon be replaced anyway) as the critical raw material for battery needs, but lithium. To secure the supply of sustainable lithium, Stellantis says it has signed two memoranda of understanding with partners – one in Europe and one in North America. This involves lithium extraction from geothermal brine. In addition, a circular economy is to be established in order to use recycled lithium in new batteries.

For the drives for the four vehicle platforms, the company is relying on a new family of electric motors. The modular system comprises three drive units, called EDM1, EDM2 and EDM3. The EDM1 (Electric Drive Module) is designed for the STLA Small and has an output of 70 kW. This motor is therefore more likely to be used in the low-cost small cars.

The EDM2 covers the range from 125 to 180 kW. With this wider range, engines of this type are meant for the Small, Medium and Large platforms. The EDM3 offers between 150 and 330 kW per engine. As the only one of the three units, there will also be an 800-volt version of the EDM3 – EDM1 and EDM2 are pure 400-volt units. The EDM3 is to be installed in the STLA Medium and Large as well as the Frame platform for the large pickups. The EDMs are to be used for front-, rear- or all-wheel drives – and also as electric motors in plug-in hybrids.

“Class-leading” efficiency and fast-charging capability

The drives are coupled with a uniform inverter. Depending on the system voltage and cost profile, either semiconductors made of silicon or silicon carbide are to be used here. The inverter is designed for up to 350 kW (all-wheel-drive models have two inverters) and can handle currents between 350 and 750 amperes.

These drives are said to achieve class-leading efficiency – Stellantis promises consumption of up to 12.0 kWh/100km. For the likewise “class-leading fast charging performance”, Stellantis does not give any kW figures, but states that up to 32 kilometres per minute can be recharged – recharged range, however, always depends on the consumption of the vehicle and is therefore less generally valid than charging performance in kilowatts.

“The customer is always at the heart of Stellantis and our commitment with this €30 billion plus investment plan is to offer iconic vehicles that have the performance, capability, style, comfort and electric range that fit seamlessly into their daily lives,” says Tavares. “The strategy we laid out today focuses the right amount of investment on the right technology to reach the market at the right time, ensuring that Stellantis powers the freedom of movement in the most efficient, affordable and sustainable way.”

With reporting by Sebastian Schaal, Germany.

Source: ‘EV Day’ webcast, stellantis.com

0 Comments