Coronavirus: Carmakers shut down plants across the globe

First carmakers announce closures of factories in Europe due to the Coronavirus crisis unfolding on the continent. PSA will lockdown all vehicle production plants in Europe by 27 March and the French carmaker is not the only one.

++ This article is being continuously updated below. ++

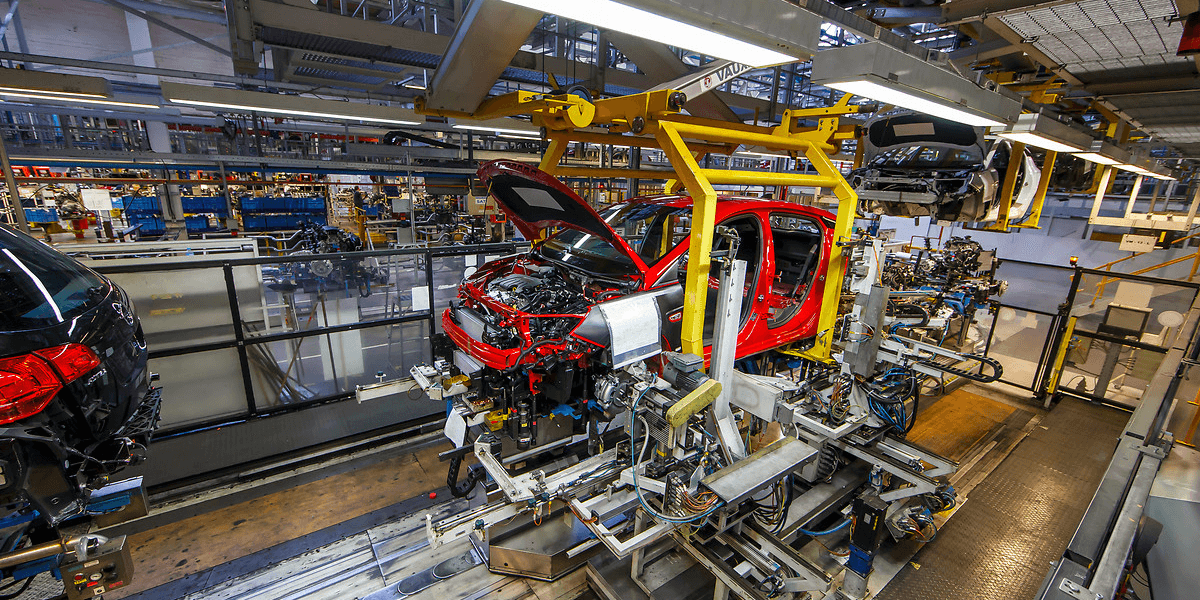

In case of PSA, the closure that started on 17 March affects the Zaragoza plant in Spain, both Opel plants in Rüsselsheim and Eisenach and most of the French plants as well as Gliwice in Poland and Ellesmere Port in the UK. Three more plants were shut down on Wednesday followed by Luton (UK) and Trnava in Slovakia on Thursday. Trnava is to build the Peugeot e-208, the Opel Corsa-e is made in Zaragoza, the PHEV versions of the Opel Grandland X in Eisenach to name a few.

FCA has also announced a production stop at most of its plants in Europe by the end of March. The plant closures also affect the production of electrified models. Fiat will close its Melfi plant near Rome, where the new PHEV version of the Jeep Renegade is being built. Series production of the new electric Fiat 500, which was presented at the beginning of March, is to take place in Mirafiori but has not yet begun. It is unclear whether the planned production start will be delayed by the plant closures.

Fiat Chrysler cited the sharp drop in demand as the reason for the production break. Therefore, not only the six Italian plants but also the production facilities in Poland and Serbia are affected. PSA, for its part, cited the “significantly accelerated rate of infection” as the reason, but also “delivery difficulties with several important suppliers”. However, the French group did not disclose the names of the suppliers.

PSA’s French competitor Renault has also closed all its French plants with immediate effect. According to the announcement, this affects 18,000 employees at twelve locations. Among them is the Flins plant, where Renault builds the Zoe. Production of the Kangoo Z.E. and Master Z.E. e-commercial vehicles is also suspended. In contrast to PSA and FCA, however, Renault does not specify a date to resume production but only states “as soon as conditions permit”. Production in other countries depends on the situation. According to French media reports, Renault has already closed its Spanish plants for the time being because of supply issues. Production of the PHEV models Captur (Valladolid) and Mégane (Palencia) has not yet started. Similar to the Fiat 500, delays are not yet foreseeable.

Nissan and Seat have also closed their Spanish plants for a week. For Nissan, the production of the e-NV200 in Barcelona is affected.

Production of the announced PHEV models at Seat has not yet started, and the Seat Mii electric e-small car is being built at Volkswagen in Bratislava. Since Slovakia declared a state of emergency, Volkswagen is preparing to stop production there, according to a report by the German public broadcaster ARD. The PHEV versions of the Porsche Cayenne and Audi Q7 are also being built in Bratislava, but the production of the recently introduced VW Touareg R has not yet started.

Besides, Magna just announced the closure of its Austrian facility in Graz until 30 March at least. The manufacturer claims not only the Covid-19 crisis as a reason but also resulting uncertainties in the supply chain that makes production planning nearly impossible. While production is suspended, the engineering team will continue to work in the home office, the company said. Magna in Graz will manufacture, among other things, the purely electric Jaguar I-Pace. Production of the electric Jaguar had to be suspended in February, and the plug-in hybrid version of the BMW 5 Series.

The consequences of the plant closures across Europe can hardly be estimated at present. If production starts up again as planned at the end of March, the impact on customers of electrified vehicles should be relatively minor – given the months of waiting for their new cars. Things could become more critical if important suppliers have to file for bankruptcy because of the production stop. Then the supply chain would be damaged more profoundly.

German manufacturers were slow to announce closures, but according to a report in the Automobilwoche, some companies are already running through scenarios when production can no longer be maintained. At Daimler, for example, personal shift handovers have been cancelled and sanitary measures taken in the canteens. Volkswagen has already closed the Autostadt in Wolfsburg, and on Wednesday the Transparent Factory in Dresden will also close for visitors. However, vehicle production is to continue for the time being.

Update 17 March: As of today, VW has also decided on far-reaching measures. In the morning, the media had reported on a letter from the works council, that the company would announce that Friday would be the last shift for the time being. Then production is to be suspended in “most European plants”.

In his digitally transmitted speech on the business figures for 2019, VW boss Herbert Diess confirmed the information. “In view of the significant current deterioration in the sales situation and the emerging uncertainty in the supply of parts to our plants, there will also be immediate interruptions in production at our brands’ sites,” Diess said. “This already applies to our Spanish plants, Setubal in Portugal, Bratislava in Slovakia and the Lamborghini and Ducati plants in Italy. Most of the Group’s other German and European plants are preparing for a production interruption, probably for two to three weeks. The primary goal is to slow down the spread of the coronavirus as much as possible.”

This also affects plants for components. Production plants in Wolfsburg, Emden, Dresden, Osnabrück, Zwickau, Bratislava (Slovakia), Pamplona (Spain), Palmela (Portugal) as well as the component plants in Braunschweig, Chemnitz, Hanover, Kassel, Salzgitter and SITECH come first.

The e-Golf, for example, is manufactured in Dresden, while the PHEV versions are produced in Wolfsburg. The Passat with plug-in hybrid is produced in Emden. As described above, numerous BEV and PHEV models are affected at the Slovakian plant in Bratislava.

According to VW CEO Diess, most of the plants in China are up and running again with 31 of 33 production facilities having resumed production, albeit in some cases still with reduced capacity. Only the plants in Changsha in the central Chinese province of Hunan and Urumqi, the capital of the disputed Uyghur autonomous region of Xinjiang, have not yet reopened.

Shortly after the Volkswagen Group, Audi announced to stop its plants worldwide to slow down the spread of the coronavirus but not until Monday. According to the VW subsidiary, production is to be shut down “in a controlled and orderly manner until the end of the week” and in the plants in Ingolstadt, Neckarsulm, Belgium, Mexico and Hungary. This affects the e-tron production in Brussels as well as the various PHEV variants at the respective factory.

In the afternoon there was also information from Ford: From Thursday onwards, Ford was to hold the lines in all European plants. This affects the German factories in Cologne and Saarlouis. For the electrified models, the plant in Valencia is also worth mentioning: This is where Ford manufactures its European hybrid vehicles and is also setting up two lines for the assembly of lithium-ion batteries. Incidentally, production in Valencia was already stopped on Monday due to national regulations. It is unclear how long the production break is to last – the communication only mentions a few weeks.

Daimler also reacted towards the evening: Due to the worsening Covid-19 pandemic, the German company has decided to suspend most of its production and work in selected administrative departments in Europe for an initial period of two weeks. The interruption affects Daimler’s European passenger car, van and commercial vehicle plants.

Update 18 March 2020: In the meantime, Tesla has also been affected, although production at Fremont continued with a special permit until now. Electric vehicle production must be suspended for the next three weeks. This was not decided by Tesla, but by the responsible sheriff of Alameda County. During this time, Tesla may only carry out minimal operational activities, such as payroll accounting.

Some counties in Silicon Valley had imposed extensive curfews, a so-called “shelter-in-place” order. Only employees working in “essential business” such as the health sector or food-related industries were exempt and electric car production does not qualify. Tesla manufactures the Model S, X, 3 and now Y in Fremont. However, Gigafactory 3 near Shanghai continues to produce Model 3 for the Chinese market.

Back to Europe: After closing its Spanish plant in Barcelona at the beginning of the week, Nissan has now also stopped production in Sunderland in the north of England. Among other things, Nissan builds the Leaf for the European market there. So far, the interruption is scheduled to last until the end of the week, and Nissan says it intends to continue monitoring the situation.

On Wednesday Toyota also decided to close its European plants “until further notice” – in some cases on the same day, but no later than Monday, 23. The plants in France, the Czech Republic, two in the United Kingdom, two in Poland and one factory in Turkey are affected. At Toyota, this naturally affects the CH-R and Corolla hybrid models (Turkey plant) and Yaris (France). The RAV4 and Camry hybrid are built in Russia, and the plant is not affected by the closure, according to the Toyota announcement. The Prius is made in Japan.

MAN Truck & Bus has also announced to close its factories for the time being. The MAN eTGE is produced in the Polish plant Września – but as a model identical in construction to the VW e-Crafter, the eTGE uses the drives from Kassel. This plant, however, is affected by the VW measures. It is unclear what effects this will have on the eTGE and the combustion engine variants. In Starachowice (also Poland), production of the MAN Lion’s City E is to start this year. The MAN plant in Steyr, Austria, will also produce a small series of all-electric trucks.

As another brand from the VW group, sports car manufacturer Porsche also announced that it would close its plants in Zuffenhausen and Leipzig for two weeks from Saturday, 21 March 2020. “In addition to the primary protection of the workforce, bottlenecks in global supply chains currently no longer permit orderly production,” Porsche stated in a press release. This affects the Taycan production in Zuffenhausen and also the PHEV variants of the Panamera in Leipzig. The Cayenne with its PHEV versions is built at the VW plant in Bratislava and thus also affected.

Volvo Cars have stopped production in Ghent, Belgium, a spokesperson, told Automobilwoche. The reasons given were a lack of employees and increasing problems in the supply chain. Only recently, Volvo had put a battery assembly line for the upcoming BEV XC40 P8 Recharge into operation at the Ghent site. It also makes the PHEV version of the XC40 there. Volvo did not say how long it will close the plant in Ghent. However, the facility in Gothenburg, Sweden, will continue production for the time being.

Lastly, during his speech on the annual figures, BMW CEO Oliver Zipse also announced closures. “As of today we are shutting down our European car plants and the Rosslyn plant in South Africa,” he said. “The interruption in production is expected to last until 19 April.” This is longer than with most other OEMs, who previously planned a production break of usually two to three weeks.

This then affects the i3 production in Leipzig and the electric Mini Cooper SE, which Mini makes in England, as well as the numerous PHEV models that BMW produces in Germany. Despite the temporary plant closures, Zipse is cautiously confident: “There is a period during Corona. And there will be a time after Corona.”

Update 19 March 2020: There had been some confusion around Tesla Fremont it appears. A spokesman for the Alameda County Sheriff’s Office said Tesla had agreed to reduce its workforce: “They assured me in a phone call to do a step-down reduction from about 10,000 to 2,500 people.” However, Alameda County later stated that the limited operation of the Tesla factory could not include the production of vehicles and announced they would take action if Tesla does not comply.

Staying in the US, General Motors, Ford and FCA now also temporarily closed their North American plants, initially until the end of March. The only relevant electric model affected is the Chevrolet Bolt.

Then back to Europe, where Hyundai ordered a two-week break at its plant in the Czech Republic to slow down the spread of the coronavirus, a spokesperson told the German Press Agency DPA. The plant in Nošovice in the Czech Republic had just started European production of the Kona Electric.

Update 20 March 2020: In agreement with the VW group, Škoda has now also stopped production at its Czech plants in Kvasiny, Vrchlabí and Mladá Boleslav. As is well known, the latter plant produces high-voltage batteries for the VW Group’s PHEV models. The closure is “initially” scheduled for two weeks, Škoda said in the announcement. The coordination team is continuously monitoring and assessing the current situation. In China, however, with the exception of Changsha, all locations where Škoda vehicles are built have resumed production.

After Volvo has already stopped production in Ghent, Belgium (including the XC40 PHEV and battery assembly for the upcoming BEV), the Swedish car manufacturer has now announced that the plants in Sweden and the US plant in South Carolina will be closed from 26 March to 14 April. Among other things, the Gothenburg plant will assemble the PHEV version of the V60. Office employees are to move to the home office from March 26 at the latest – but unlike the plants, no details are given here as to how long this measure is to take. Meanwhile, the Chinese plants (where the S90 PHEV is built, among other things) are open again.

Update 21 March 2020: In Aachen, e.GO Mobile is following suit and due to the effects of the pandemic, production of e.GO Life will be temporarily interrupted – starting Monday, March 23, initially for four weeks. The manufacturer states that this “also anticipates production bottlenecks that are expected in the supply chain in the coming weeks due to the production stops of the major car manufacturers”. The management is reassessing the situation daily on the basis of the current information situation. “We have now solved many of the problems of a capital-intensive start-up. But we are still in the middle of the ramp-up. The measures are hitting us at a sensitive phase. We will probably need help from the federal or state governments to survive the corona crisis,” says CEO Günther Schuh.

US startup Rivian is also interrupting production preparations for its debut electric vehicle, the R1T electric pickup. As the company announces on Twitter, all US locations will be closed for the safety of the more than 2,000 employees. This affects the headquarters in Plymouth, Michigan, as well as branches in Normal, Illinois, San Jose and Irvine, California. The company has no comment on how long the closure is to last.

While General Motors announced two days ago that it will also temporarily close its North American plants, the conversion work on the production lines of the Hamtramck plant in Detroit will apparently start as planned despite the virus threat. As reported, GM plans to convert the production facility into a pure electric car plant.

Also in the US, BMW has decided to stop the lines at their plant in Spartanburg, South Carolina. Among other things, the Munich carmaker produces batteries for its PHEV models on site. The production stop is to be effective starting from April 3 for an estimated two weeks.

Update 23 March 2020: Tesla has confirmed that the Fremont plant will be closed as of today. Gigafactory 2 in New York State for solar roofs will also be temporarily closed. In both cases, a minimum operation is to be maintained, for example to ensure the supply of parts and supplies, but also the operation of the networked Tesla vehicles and the charging and energy infrastructure – “in accordance with the instructions of the local, state and federal authorities”.

The company is also working on implementing “contactless deliveries” at many locations, the company writes in an investor letter. For example, this should make it possible to unlock the trunk so that a delivery service can deliver the ordered goods to the car without having to contact the Tesla driver.

In the letter to the investors, Tesla also states that production is to continue at Gigafactory 1 in Nevada. However, this presents a new challenge for the electric car manufacturer: Battery partner Panasonic has withdrawn its 3,500 employees working there from the Nevada plant. According to the Japanese, the workforce should not be put at risk in the corona crisis. The measure is to apply for 14 days initially. Without the Panasonic battery cells, it is questionable how Tesla and its employees will be able to maintain parts of the production there. In the Gigafactory 1, the Tesla staff will assemble the battery cells (from Panasonic employees), as well as electric motors and the energy storage units Powerwall and Powerpack.

Like Tesla, BYD is also closing its Californian plant. In a statement, the Chinese company states that production will be “temporarily suspended for the next two weeks” – “or until we receive further instructions or information that will allow us to resume operations safely”. BYD also refers to the suppliers “who are also facing these unprecedented challenges”. At the Lancaster plant, BYD manufactures electric buses for the American market, among other things.

Update 26 March 2020: Reports are coming in that the production stoppages caused by the coronavirus pandemic will last longer than initially announced by some manufacturers. “A ramp-up before the end of the Easter holidays is not expected”, said Hildegard Mueller, President of the German Manufacturers Association VDA. This would mean that production would not resume before mid-April.

VW CEO Herbert Diess had also already indicated that the production break would last longer than the two to three weeks mentioned so far. “It is likely that the measures will last longer”, Diess said.

There are similar plans at Ford: The US manufacturer has now announced that production, at least at the North American plants, will not restart on 30 March as originally planned. How long the break will last is something the Board of Directors will probably keep open – Ford has not yet given a new date for the production restart.

Update 27 March 2020: VW has named concrete measures for the indicated production pause. Production at the German plants of the Volkswagen Passenger Cars brand, Volkswagen Commercial Vehicles and Volkswagen Group Components will be suspended for a further four working days until 9 April. The plants in Dresden, Emden, Osnabrück, Wolfsburg, Zwickau and Volkswagen Commercial Vehicles in Hanover are affected, as are the Volkswagen Group component plants in Brunswick, Kassel, Salzgitter, Chemnitz, Hanover component plants and the German plants of SITECH.

Tesla announced plans to temporarily shut down most of the operations in Gigafactory 1 in Nevada due to the Corona pandemic. After Tesla’s battery partner Panasonic had already withdrawn its 3,500 employees working there, Tesla is now planning to reduce its on-site personnel by around 75 per cent in the coming days.

Update 31 March 2020: Porsche is extending the production break at its plants in Stuttgart-Zuffenhausen and Leipzig, initially set at two weeks, by at least another week. There are still bottlenecks in the global supply chains planned, a spokesperson said. This affects the Taycan production in Zuffenhausen and also the production of the PHEV variants of the Panamera in Leipzig.

Update 01 April 2020: Production at the German plants of Volkswagen Passenger Cars, Volkswagen Commercial Vehicles and Volkswagen Group Components will be suspended for a further five working days until April 19. This is mainly due to the ongoing decline in demand for vehicles and the continuing challenges in the supply chain. Furthermore, Hyundai is extending the production pause at its Czech plant in Nosovice until 14 April.

Update 07 April 2020: BMW is extending the production pause at their plants in Europe and the USA until 30 April. Previously, BMW had planned production stoppages until 19 April.

Porsche is also extending the break on the production lines. After the Stuttgart VW subsidiary had already extended the production break until Easter, it has now been decided that no cars will be built in Zuffenhausen and Leipzig in the week after Easter either. The reason is still the same: there are still bottlenecks in the global supply chains, which do not allow an orderly restart of production.

Update 08 April 2020: In an email to employees, Tesla explained that they currently expect to resume regular production at US plants next month on 4 May. The email also announced salary cuts: “30% for Vice Presidents and above, 20% for Directors and above, and 10% for everyone else.” These are expected to be in place until the end of the second quarter. Also: “Employees who cannot work at home and have not been assigned to critical work onsite will be furloughed. Under furlough, you remain an employee of Tesla (without pay) and retain your healthcare benefits.” For those working for Tesla in other parts of the world, the letter states: “For non-US employees, there will also be comparable reductions, of which the specifics will be communicated by the local leadership team in accordance with local laws and works-councils.”

Update 09 April 2020: The Kurzzeitarbeit (shortened working hours) that Daimler AG began on 6 April will continue for the majority of its production at its passenger car, van and commercial vehicle plants and administrative departments until April 30.

Škoda has continued the production stop in the three Czech plants Mlada Boleslav, Vrchlabi and Kvasiny until April 27.

>> With reporting by our staff in Germany.

groupe-psa.com, fcaemea.com, renault.com, lemonde.fr, automobilwoche.de, ard.de, steiermark.orf.at, Updates: orf.at (Magna), spiegel.de (VW), volkswagen-newsroom.de, automobilwoche.de (Audi), ford.com, volkswagen-newsroom.com, vwn-presse.de, daimler.com (most in German), wired.com, cnbc.com (Tesla), autocar.co.uk, nissannews.com (Nissan), toyota.eu (Toyota), mantruckandbus.com (MAN), porsche.com (Porsche), automobilwoche.de (Volvo, in German), bmwgroup.com (BMW), electrek.co (Tesla, update 19 March), greencarcongress.com (GM, Ford, FCA), automobilwoche.de (Hyundai, in German), skoda-storyboard.com (Skoda), volvocars.com, pressebox.de (e.GO Mobile in German), twitter.com, techcrunch.com (Rivian), electrek.co (GM), bmwblog.com (BMW), tesla.com, techcrunch.com, byd.com, handelsblatt.com (VDA), ford.com, volkswagen-newsroom.com, reuters.com (Tesla), theverge.com (Tesla), automobilwoche.de (Porsche in German), volkswagen-newsroom.com, automobilwoche.de (Hyundai in German), automobilwoche.de (BMW in German), automobilwoche.de (Porsche in German) electrek.co, cnbc.com (Tesla plans), daimler.com (in German), kfz-betrieb.vogel.de (about Skoda, in German)

0 Comments